Collagen adhesive and preparation method and application thereof

A collagen and adhesive technology, applied in the direction of protein waste adhesives, adhesive additives, non-polymer adhesive additives, etc., to achieve the effects of extending the application period, slowing down the reaction rate, and good environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

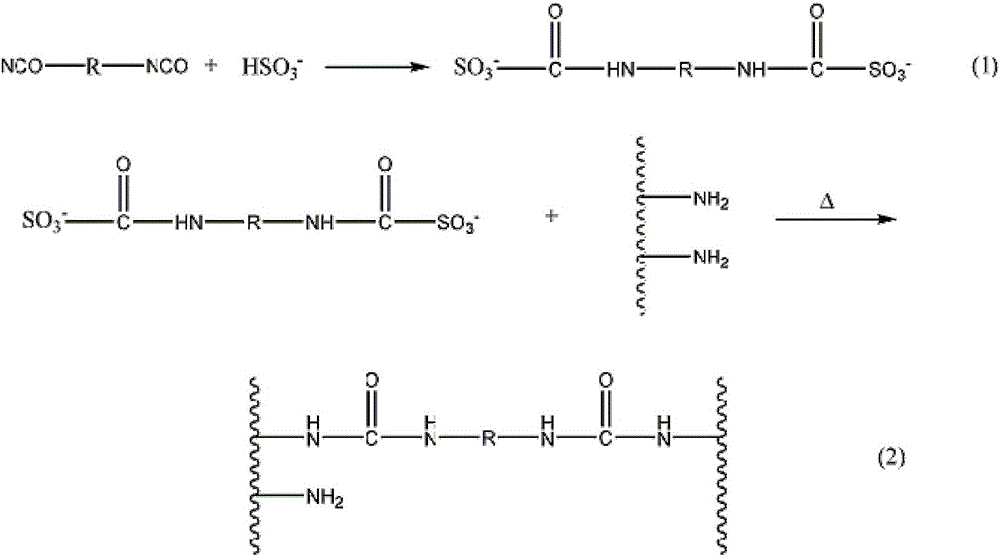

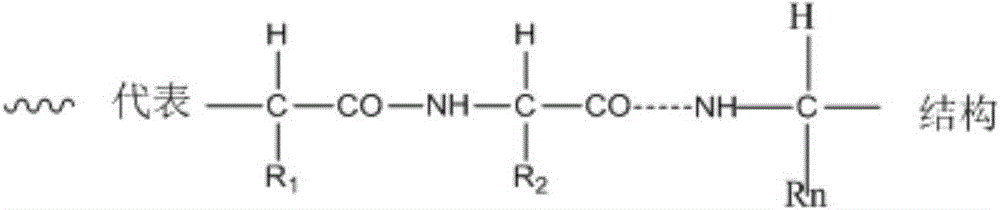

[0028] The preparation method of the collagen type adhesive involved in the present invention not only does not cause the harm of releasing free formaldehyde, but also effectively and rationally utilizes leather solid waste and realizes its high-value conversion. Material material, green and environmentally friendly, easy to biodegrade. The synthetic route is as follows:

[0029]

[0030] Wherein, reaction formula (1) is the process of sulfite blocked isocyanate group; Reaction formula

[0031] (2) It is the process of cross-linking reaction between blocked isocyanate group and amino group in gelatin,

[0032]

[0033] Specifically include the following steps:

[0034] Step 1: Preparation of gelatin aqueous solution:

[0035] Weigh 10g to 15g of gelatin, add it to deionized water, swell at room temperature for 30min, and then heat to 60°C until the gelatin is completely dissolved. After the gelatin is dissolved, add 30% of the dry weight of gelatin to sodium chloride ...

Embodiment 1

[0045] A preparation method of collagen-based wood adhesive, comprising the steps of:

[0046] Step 1: Weigh 10g of gelatin, add 100mL of deionized water, swell at room temperature for 30min, then heat to 60°C, after the gelatin is completely dissolved, add 3g of sodium chloride to obtain a gelatin aqueous solution;

[0047] Step 2: Weigh 25 g of polyisophorone diisocyanate, add 0.4% of its mass of sodium bisulfite, and stir at room temperature for 30 minutes to obtain blocked polydiphenylmethane diisocyanate;

[0048] Step 3: Add blocked polydiphenylmethane diisocyanate with 10% gelatin mass to the aqueous gelatin solution, and stir evenly at room temperature for 1 hour to obtain a gelatin solution modified with blocked isocyanate groups;

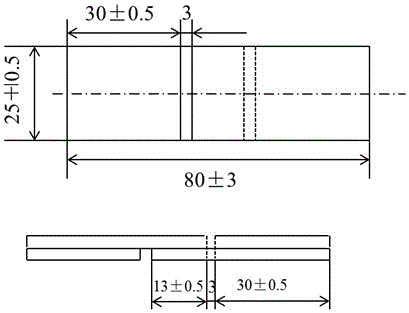

[0049] Step 4: Apply the synthetic collagen adhesive evenly on both sides of the pine veneer (the amount of double-sided glue is 300g / m 2 ), hot pressing at 120°C and 1.0Mpa for 6 minutes after embryo formation, take 3 groups of samples, ...

Embodiment 2

[0051] A preparation method of collagen-based wood adhesive, comprising the steps of:

[0052] Step 1: Weigh 10g of gelatin, add 100mL of deionized water, swell at room temperature for 30min, then heat to 60°C, after the gelatin is completely dissolved, add 3g of sodium chloride to obtain a gelatin aqueous solution;

[0053] Step 2: Weigh 25 g of polyphenyl polymethyl polyisocyanate, add 0.5% of its mass of sodium bisulfite, and stir at room temperature for 30 minutes to obtain blocked polyphenyl polymethyl polyisocyanate;

[0054] Step 3: Adding blocked polyphenyl polymethyl polyisocyanate with 15% gelatin mass to the aqueous gelatin solution, and uniformly stirring at room temperature for 1 hour to obtain a blocked isocyanate group-modified gelatin solution;

[0055] Step 4: Apply the synthetic collagen adhesive evenly on both sides of the pine veneer (the amount of double-sided glue is 300g / m 2 ), hot pressing at 120°C and 1.0Mpa for 6 minutes after embryo formation, take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com