Preparation method of rare-earth aluminoborate fluorescent powder

A boro-aluminate and phosphor technology, applied in the field of red phosphor, can solve the problems of crystalline silicon not reaching the theoretical limit, low efficiency of single-crystalline silicon solar cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

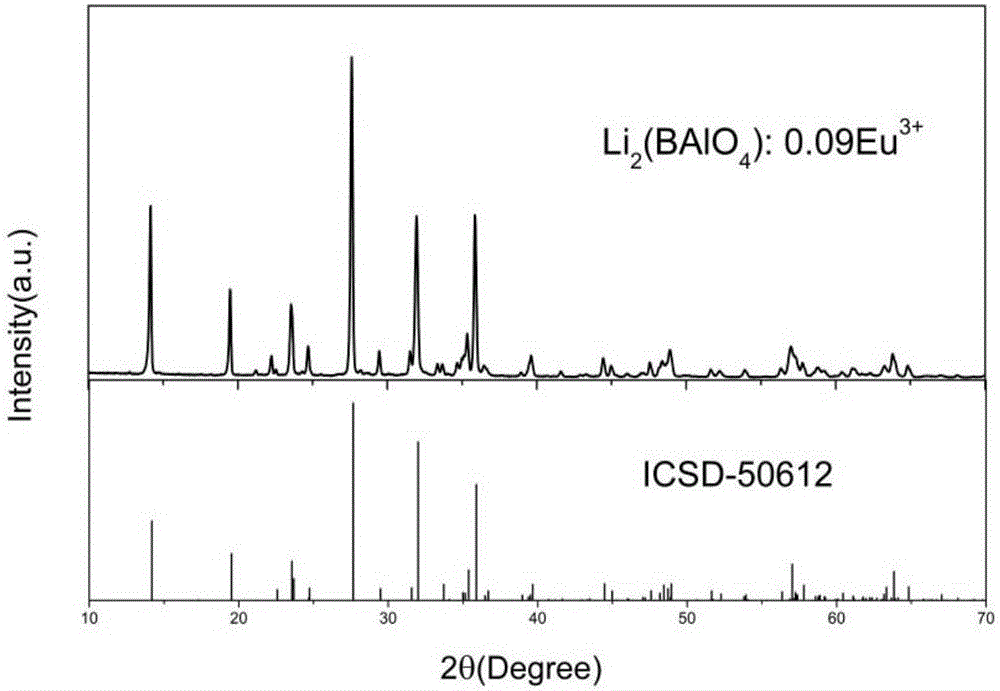

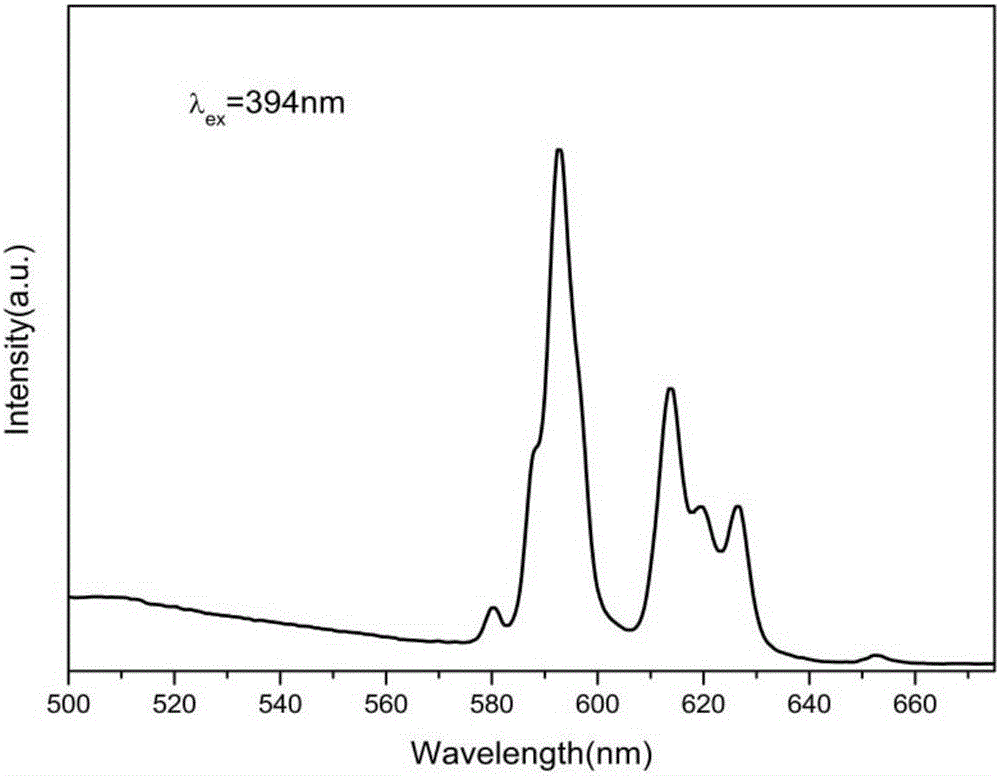

[0017] Example 1: Li 2 AlBO 4 Phosphor powder

[0018] Take analytically pure lithium carbonate Li 2 CO 3 , aluminum oxide Al 2 o 3 , boric acid H 3 BO 3 The raw materials are prepared according to the chemical formula ratio, and the raw material ratio is shown in Table 1.

[0019] Table 1

[0020] raw material Li 2 CO 3

Al 2 o 3

h 3 BO 3

Weight (g) 0.3695 0.2549 0.3092

[0021] Accurately weigh the above raw materials, fully grind them in an agate crucible, mix them evenly, and put them into a ceramic crucible.

[0022] Put the sample into the muffle furnace according to the set procedure, first rise from room temperature to 350°C for 60 minutes after 60 minutes, and then rise to 820°C for 3 hours after 180 minutes. After the calcination process, the sample is cooled to room temperature with the furnace and taken out After taking it out, grind it into powder with an agate crucible to get Li 2 AlBO 4 Material.

Embodiment 2

[0023] Example 2: Li 1.97 AlBO 4:0.03Eu 3+ Phosphor powder

[0024] Take analytically pure lithium carbonate Li 2 CO 3 , aluminum oxide Al 2 o 3 , boric acid H 3 BO 3 and europium oxide Eu 2 o 3 The raw materials are prepared according to the chemical formula ratio, and the raw material ratio is shown in Table 2.

[0025] Table 2

[0026] raw material Li 2 CO 3

al 2 o 3

h 3 BO 3

Eu 2 o 3

Weight (g) 0.3639 0.2549 0.3092 0.0264

[0027] Accurately weigh the above raw materials, fully grind them in an agate crucible, mix them evenly, and put them into a ceramic crucible.

[0028] Put the sample into the muffle furnace according to the set procedure, first rise from room temperature to 350°C for 60 minutes after 60 minutes, and then rise to 820°C for 3 hours after 180 minutes. After the calcination process, the sample is cooled to room temperature with the furnace and taken out After taking it out, grind it into p...

Embodiment 3

[0029] Example 3: Li 1.95 AlBO 4:0.05Eu 3+ Phosphor powder

[0030] Take analytically pure lithium carbonate Li 2 CO 3 , aluminum oxide Al 2 o 3 , boric acid H 3 BO 3 and europium oxide Eu 2 o 3 The raw materials are prepared according to the chemical formula ratio, and the raw material ratio is shown in Table 3.

[0031] table 3

[0032] raw material SrCO 3

al 2 o 3

h 3 BO 3

Eu 2 o 3

Weight (g) 0.3602 0.2549 0.3092 0.044

[0033] Accurately weigh the above raw materials, fully grind them in an agate crucible, mix them evenly, and put them into a ceramic crucible.

[0034] Put the sample into the muffle furnace according to the set procedure, first rise from room temperature to 350°C for 60 minutes after 60 minutes, and then rise to 820°C for 3 hours after 180 minutes. After the calcination process, the sample is cooled to room temperature with the furnace and taken out After taking it out, grind it into powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com