Synthesis method of broad-spectrum and high-efficiency crude oil demulsifier

A crude oil demulsifier and a synthesis method technology are applied in the field of chemical treatment agent for oilfield development and production fluid, which can solve the problems of large amount of demulsifier, difficulty in taking into account oil and water, poor adaptability, etc., and achieves good demulsification effect and strong wetting and penetrating ability. , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

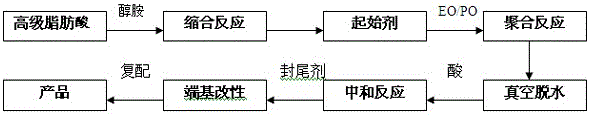

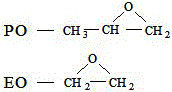

Method used

Image

Examples

Embodiment 1

[0021] ⑴. Put 100kg of lauric acid and 160kg of monoethanolamine into the reaction equipment. After vacuuming for 15 minutes, replace it with nitrogen twice, raise the temperature to 50°C, and start stirring; continue to raise the temperature to 110-120°C, keep the temperature for 2 hours, and gradually raise the temperature (15-20°C in one stage), until the temperature reaches 170°C.

[0022] (2) Heating up and vacuum dehydration until the temperature reaches 165-170°C and no more moisture is produced to produce alkanolamides.

[0023] (3) When the temperature is lowered to 100°C, vacuum for 15 minutes until the pressure in the reactor reaches the minimum, add 15kg of potassium hydroxide (it can be a 30-50% aqueous solution of potassium hydroxide), and stir evenly; steadily raise the temperature to 110-140°C, and vacuum dehydrate until After the water is removed, the temperature is raised to 140°C; nitrogen is filled to normal pressure, and 6500kg of propylene oxide is added ...

Embodiment 2

[0029] ⑴. Throw 100kg of stearic acid and 80kg of diethanolamine into the reaction equipment, vacuum for 15 minutes, replace with nitrogen twice, raise the temperature to 50°C, start stirring; continue to heat up to 110-120°C, keep the temperature for 2h, stage Raise the temperature (15-20°C in one stage) until the temperature reaches 170°C.

[0030] (2) Heating up and vacuum dehydration until the temperature reaches 165-170°C and no more moisture is produced to produce alkanolamides.

[0031] (3) When the temperature is lowered to 100°C, vacuum for 15 minutes until the pressure in the reactor reaches the minimum, add 20kg of potassium hydroxide (it can be a 30-50% aqueous solution of potassium hydroxide), and stir evenly; steadily raise the temperature to 110-140°C, and vacuum dehydrate until After the water is removed, the temperature is raised to 140°C; nitrogen is filled to normal pressure, 8500kg of propylene oxide is added dropwise in sequence and proportion, and the rea...

Embodiment 3

[0037] (1) Throw 110kg of behenic acid and 120kg of diethanolamine into the reaction equipment, vacuum for 15 minutes, replace with nitrogen twice, raise the temperature to 50°C, start stirring; continue to raise the temperature to 110-120°C, keep the temperature for 2 hours, stage by stage Raise the temperature (15-20°C in one stage) until the temperature reaches 170°C.

[0038] (2) Heating up and vacuum dehydration until the temperature reaches 165-170°C and no more moisture is produced to produce alkanolamides.

[0039] (3) When the temperature is lowered to 100°C, vacuum for 15 minutes until the pressure in the reactor reaches the minimum, add 15kg of potassium hydroxide (it can be a 30-50% aqueous solution of potassium hydroxide), and stir evenly; steadily raise the temperature to 110-140°C, and vacuum dehydrate until After the water is removed, the temperature is raised to 140°C; nitrogen is filled to normal pressure, and 7600kg of propylene oxide is added dropwise in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com