Method for extracting capsicum seed oil

A technology for chili seed oil and chili seed powder, which is applied in the production of edible oil/fat, fat oil/fat, and fat production, can solve the problems of small batch production, complicated operation, low safety, etc., and achieves mature production equipment, Simple process and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

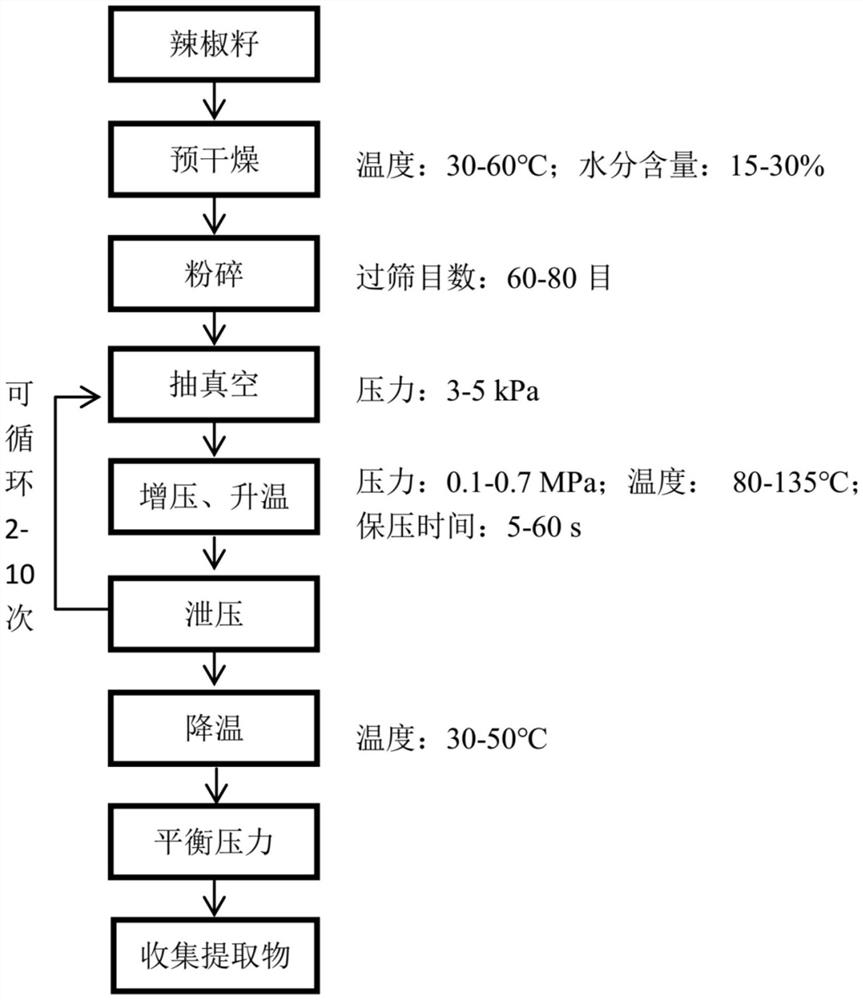

[0079] Such as figure 1 Shown, the present invention provides a kind of method that utilizes instantaneous flash processing to extract capsicum seed oil in capsicum seed, mainly comprises the steps:

[0080] (1) pre-drying the chili seeds, the drying temperature is 60°C, and the moisture content of the chili seed powder after pre-drying is 15%;

[0081] (2) sieve after pulverizing the pre-dried capsicum seeds with a pulverizer, and the sieve mesh number is 60;

[0082] (3) After the capsicum seeds after pulverizing and sieving are placed in the processing bin of the instantaneous flash evaporation equipment, the processing bin is vacuumized to reduce the vacuum to 3kPa;

[0083] (4) Pass hot steam into the processing chamber to pressurize and raise the temperature, raise the temperature to 80°C, increase the pressure to 0.1MPa, and hold the pressure for 5s;

[0084] (5) Open the pressure relief valve, and carry out instantaneous flash steaming process to the capsicum seed powd...

Embodiment 2

[0099] Such as figure 1 Shown, the present invention provides a kind of method that utilizes instantaneous flash processing to extract capsicum seed oil in capsicum seed, mainly comprises the steps:

[0100] (1) pre-drying the chili seeds, the drying temperature is 50°C, and the moisture content of the chili seed powder after pre-drying is 20%;

[0101] (2) sieve after pulverizing the pre-dried capsicum seeds with a pulverizer, and the sieve mesh number is 70;

[0102] (3) After the capsicum seeds after pulverizing and sieving are placed in the processing bin of the instantaneous flash evaporation equipment, the processing bin is vacuumized to reduce the vacuum to 4kPa;

[0103] (4) Pass hot steam into the processing chamber to pressurize and raise the temperature, raise the temperature to 100°C, increase the pressure to 0.3MPa, and hold the pressure for 30s;

[0104] (5) Open pressure relief valve, carry out instantaneous flashing process to the capsicum seed powder in proc...

Embodiment 3

[0120] Such as figure 1 Shown, the present invention provides a kind of method that utilizes instantaneous flash processing to extract capsicum seed oil in capsicum seed, mainly comprises the steps:

[0121] (1) pre-drying the chili seeds, the drying temperature is 50°C, and the moisture content of the chili seed powder after pre-drying is 20%;

[0122] (2) sieve after pulverizing the pre-dried capsicum seeds with a pulverizer, and the sieve mesh number is 70;

[0123] (3) After the capsicum seeds after pulverizing and sieving are placed in the processing bin of the instantaneous flash evaporation equipment, the processing bin is vacuumized to reduce the vacuum to 4kPa;

[0124] (4) Pass hot steam into the processing chamber to pressurize and raise the temperature, raise the temperature to 100°C, increase the pressure to 0.3MPa, and hold the pressure for 30s;

[0125] (5) Open pressure relief valve, carry out instantaneous flashing process to the capsicum seed powder in proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com