Separation and recovery method for ferrum and manganese in electrolytic manganese residues

An electrolytic manganese slag, separation and recovery technology, applied in the field of iron and manganese phase, can solve the problems of waste of iron and manganese resources, difficulty in sorting iron and manganese roasted products, environmental pollution, etc., achieve efficient separation and recovery, reduce ecological risks, Reduce the effect of large heaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

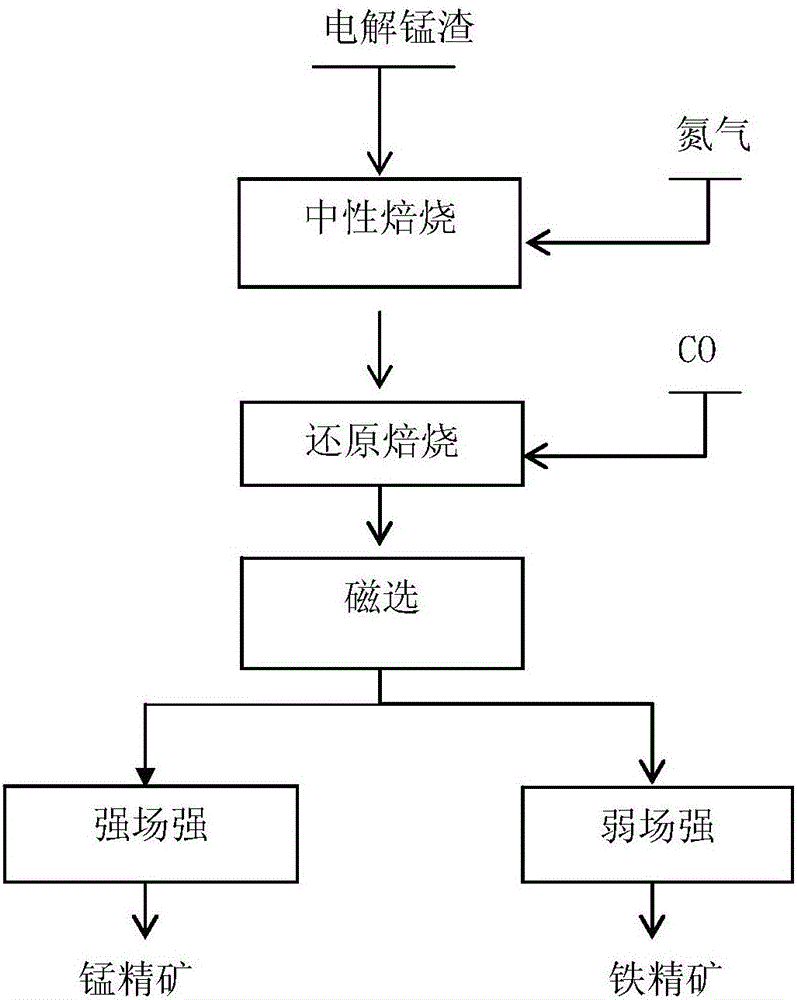

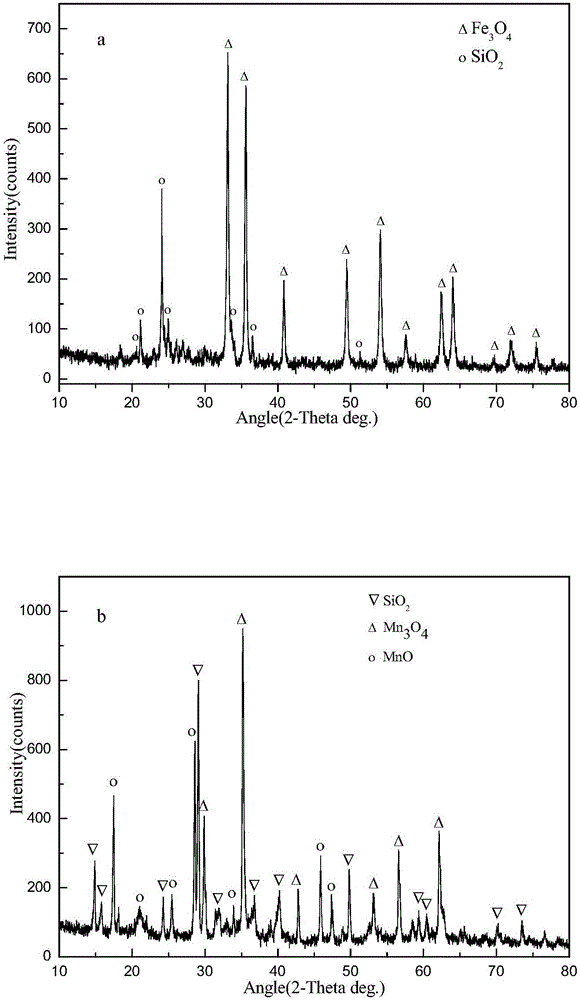

[0038] Embodiment 1: Neutral-reduction roasting-magnetic separation of electrolytic manganese slag (bixbyite)

[0039] A. According to figure 1 The technological process is that the electrolytic manganese slag is dried and crushed to a certain particle size, and then reduced and roasted. The neutral roasting conditions are controlled at a roasting temperature of 700°C, roasting time of 30 minutes, and a gas-to-material ratio of 1-10Kg / L.

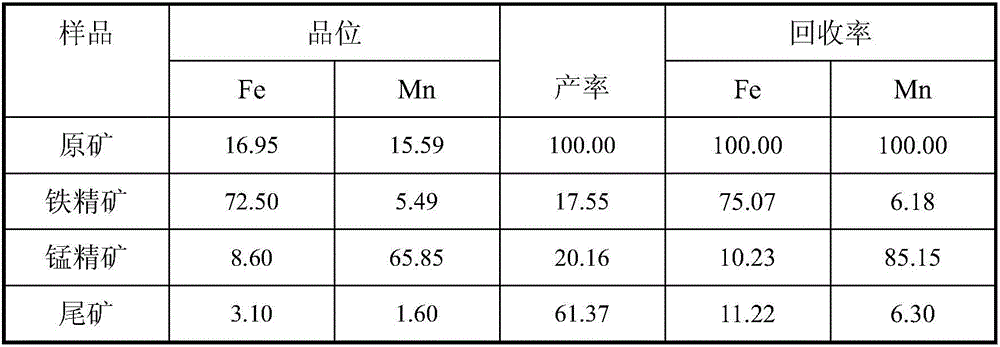

[0040] B. Carry out reduction roasting on the neutral roasted product, the roasting temperature is 750°C, the roasting time is 50min, then the roasted product is crushed and dispersed by mechanical ball milling, and then added to the magnetic separator after adding water and using PVP as the dispersant to disperse and adjust the ferromagnetic The separation intensity is 950G, and the manganese magnetic separation intensity is 12000G, and the iron and manganese concentrates are obtained under the conditions of weak field strength and strong f...

Embodiment 2

[0043] Embodiment 2: reduction roasting-magnetic separation of electrolytic manganese slag (bixbyite)

[0044] The electrolytic manganese slag with a certain particle size is directly reduced and roasted, the roasting temperature is 750 ° C, the roasting time is 50 minutes, and then the roasted product is mechanically ball milled and dispersed, and water is added to the magnetic separator to adjust the ferromagnetism. The separation intensity is 950G, and the manganese magnetic separation intensity is 12000G. Under the conditions of weak magnetic field and strong magnetic field, iron and manganese concentrates are obtained respectively. The results of magnetic separation are shown in Table 4. Compared with Example 1, it can be seen that after direct reduction and roasting of high-iron electrolytic manganese slag, the cascade magnetic separation process cannot achieve a good separation effect on iron and manganese, and the iron grade in the iron concentrate is only 31.85%. , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com