Preparation method of armor material

An armor material, copper alloy technology, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of large specific surface area, easy agglomeration, small size, etc., to achieve simple process operation, avoid uneven distribution, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing an armor material, and the specific steps are as follows:

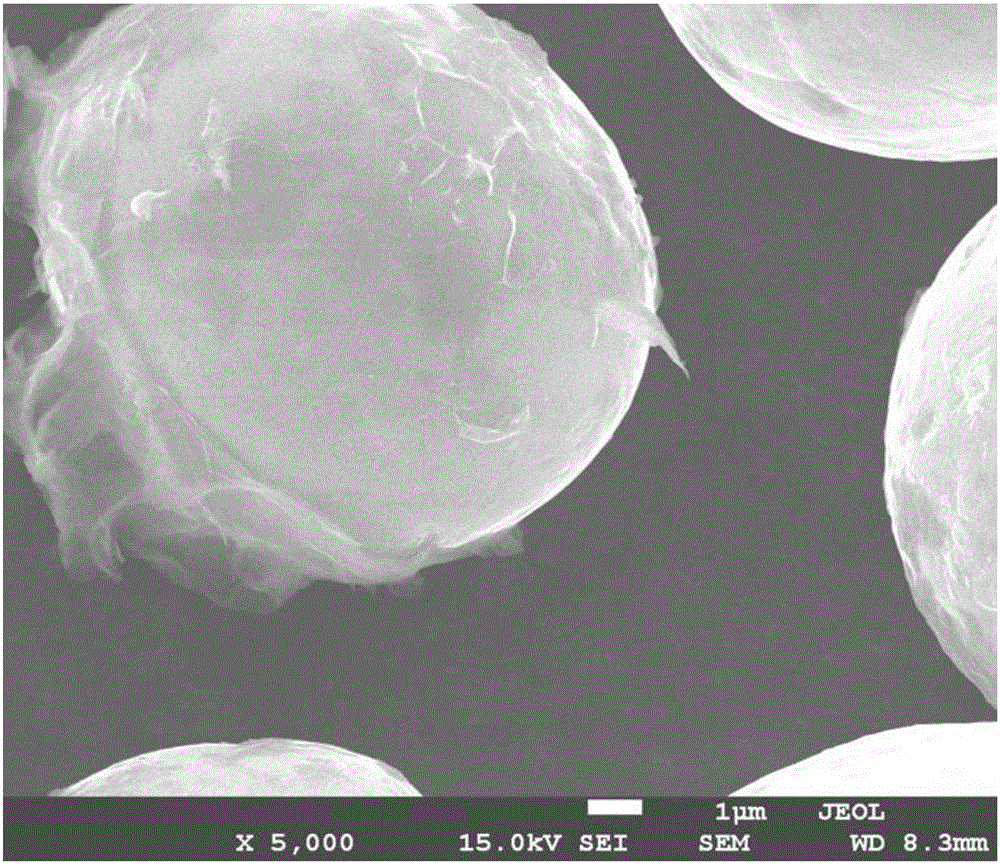

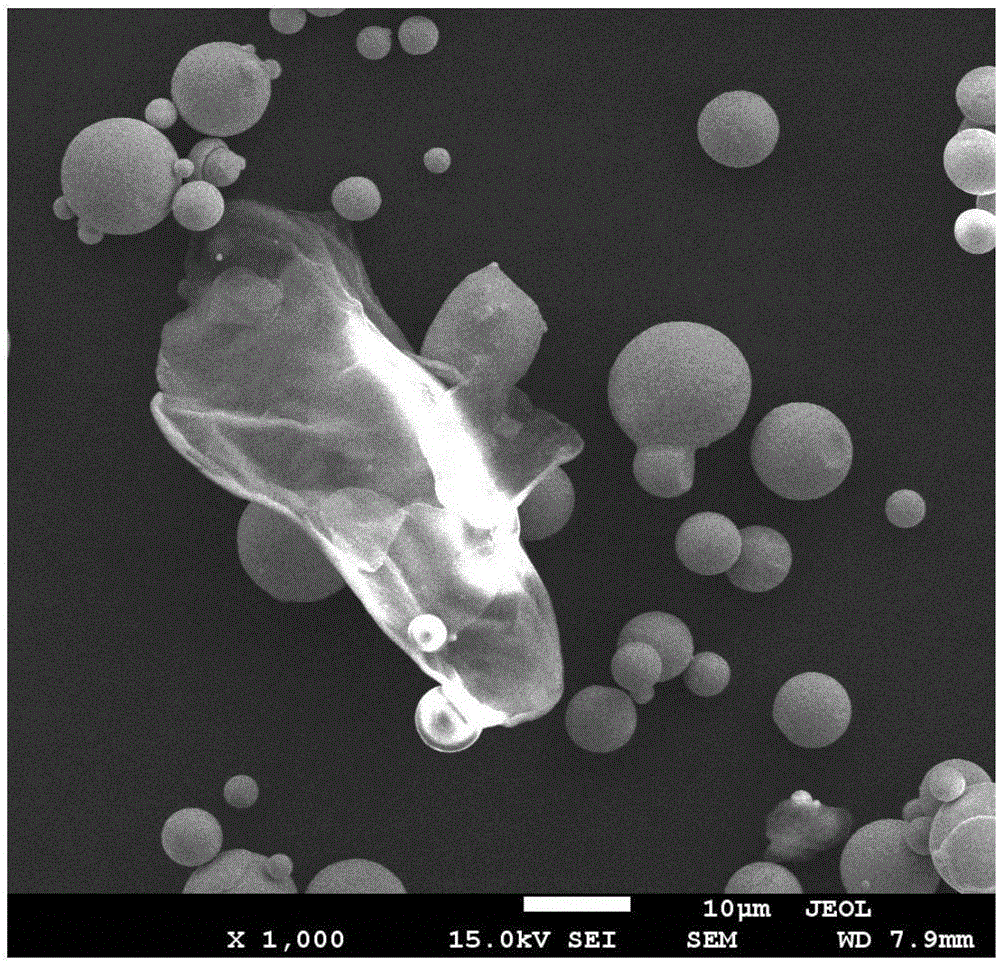

[0035] The graphene-coated copper alloy powder includes the following components in parts by weight: 0.05% of graphene and 99.95% of copper alloy. Graphene can be prepared by Hummer's method. The copper alloy has the following components by mass percentage: Pb: 0.003%; O: 0.02%; the balance is Cu and unavoidable impurities; the particle size of the copper alloy powder is 60 μm.

[0036] 1) after the graphene is ultrasonically dispersed in the alcohol solution of 95% by concentration, then it is 9000rpm to place the rotating speed, and the linear speed is in the centrifugal nano-disperser of 115m / s to obtain the graphene alcohol solution after the centrifugal dispersion, the In the graphene alcohol solution, graphene nanosheets with less than 10 layers account for more than 90% of all graphene nanosheets;

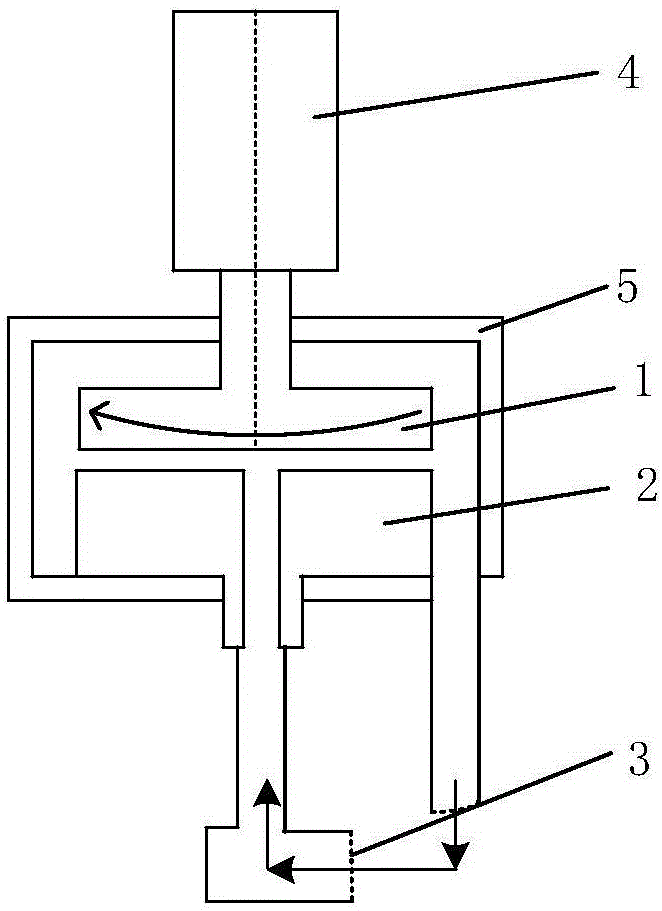

[0037] 2) The graphene nanosheet organic solution is ato...

Embodiment 2

[0041] The graphene-coated copper alloy powder includes the following components in parts by weight: 9% graphene and 91% copper alloy. The copper alloy has the following components by mass percentage: Bi: 0.01%; O: 0.04%; the balance is Cu and unavoidable impurities. The particle size of the copper alloy powder was 10 μm.

[0042] 1) after the graphene is ultrasonically dispersed in the alcohol solution of 95% concentration, then it is 8000rpm to place the rotating speed, and the linear speed is in the centrifugal nano-disperser of 100m / s to obtain the graphene alcohol solution after the centrifugal dispersion, the In the graphene alcohol solution, graphene nanosheets with less than 10 layers account for more than 90% of all graphene nanosheets;

[0043] 2) The graphene nanosheet organic solution is atomized into small droplets through a spray device with a shower mesh size of 100 μm under pressure, and evenly sprinkled on the copper and / or copper alloy powder rotating in a h...

Embodiment 3

[0047] The graphene-coated copper alloy powder includes the following components in parts by weight: 5% graphene and 95% copper alloy. The copper alloy has the following components by mass percentage: Bi≤0.005%; Pb: 0.003%; the balance is Cu and unavoidable impurities. The particle diameter of the copper alloy powder was 100 μm.

[0048]1) After graphene is ultrasonically dispersed in an organic solvent (concentration is 20% alcohol solution), then it is placed in a centrifugal nano-disperser with a speed of 7000rpm and a line speed of 85m / s to obtain the centrifugally dispersed graphene nanometer. Sheet organic solution, in the graphene nanosheet organic solution, the number of graphene nanosheet layers below 10 accounts for more than 90% of all graphene nanosheets;

[0049] 2) The graphene nanosheet organic solution is atomized into small droplets through a spray device with a shower mesh size of 180 μm under pressure, and evenly sprinkled on the copper and / or copper alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com