Coupled coating with high strength and high toughness and preparation method thereof

A high-toughness, high-strength technology, applied in the direction of coating, metal material coating process, fusion spraying, etc., to achieve the effect of simple equipment and process, improved strength and toughness, and improved bonding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

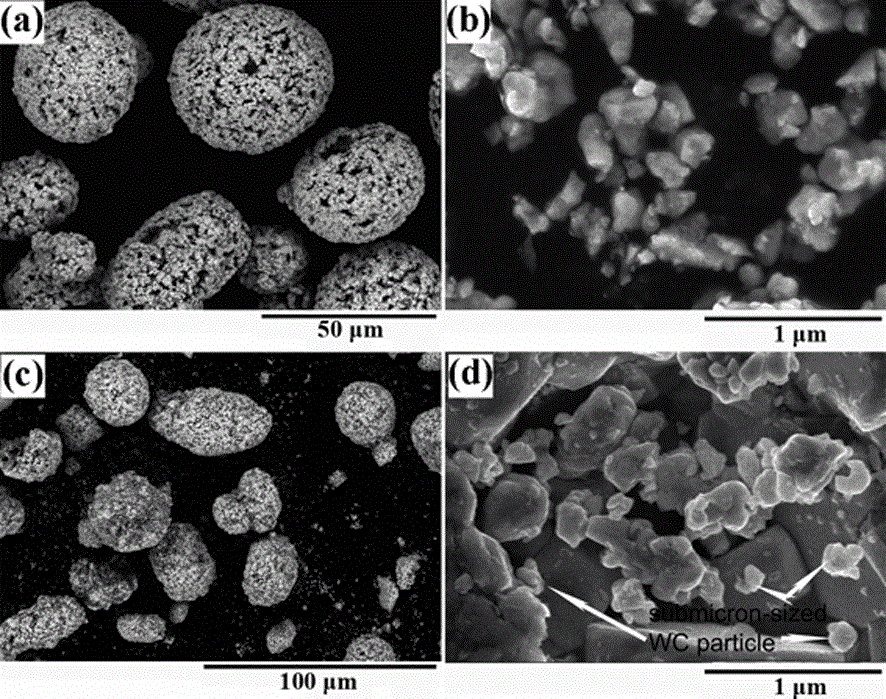

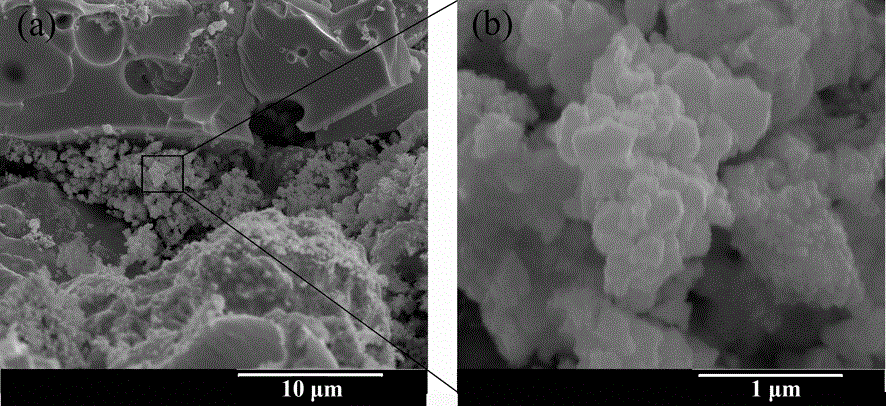

[0039] In this example, the commercially available WC-Co powder (with a particle size of about 30 μm) is used for the micron powder, and the commercially available WC powder (with a particle size of about 80 nm) is used for the nano-powder. The proportion of the nano-powder in the micro / nano coupling powder is 5wt%, the thickness of the coating is about 200 μm, and the specific preparation method of the coating is as follows:

[0040] 1. Use deionized water as a solvent, add 2wt% PVP as a binder, and add 5wt% coupling powder to configure a slurry. Add balls according to the ball-to-material ratio of 20:1. The ball milling speed is 150r / min, and the ball milling time is 4h, spray granulation within 1 hour after the completion of ball milling, the atomization gas is compressed air during granulation, the pressure is 0.3MPa, the slurry delivery rate is 15ml / min, the drying temperature is 200°C, take 150-500 mesh sieve The powder between the nets is the raw material for thermal sp...

Embodiment 2

[0047] In this example, the specific preparation method of the micro / nano coupling coating is basically the same as that in Example 1, except that the proportion of nano powder in the coupling powder is 3wt%.

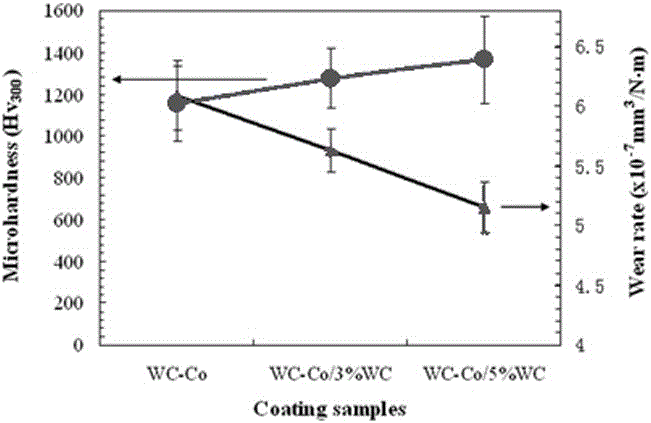

[0048] The micro / nano-coupling coating prepared above was subjected to the following performance tests:

[0049] 1. Microhardness of the coating: The average hardness of the coating measured by the coating microhardness test method is 1275.4HV (74.7HRC).

[0050] 2. Coating wear rate: using the coating friction and wear test method, the measured coating wear rate is 5.52×10 -7 mm 3 / N·m, the results show that the wear resistance of the coating is better than that of the conventional coating.

Embodiment 3

[0052] In this example, the specific preparation method of the coupling coating is basically the same as that in Example 1, the difference is that the powders used are micron Al 2 o 3 (particle size about 50μm) and nano-Al 2 o 3 (particle size about 30nm) powder.

[0053] The micro / nano-coupling coating prepared above was subjected to the following performance tests:

[0054] 1. Microhardness of the coating: The average hardness of the coating measured by the coating microhardness test method is 1075.4HV (70.7HRC).

[0055] 2. Coating wear rate: using the coating friction and wear test method, the measured coating wear rate is 6.52×10 -7 mm 3 / N·m, the results show that the wear resistance of the coating is better than that of the conventional coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com