Mercaptoacetone oxime cleaner production method and system

A technology for methylthioacetaldoxime and clean production, which is applied in the field of clean production methods and systems of methylthioacetaldoxime, can solve problems such as a large amount of waste salt, pollute the environment, etc. The effect of salty wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

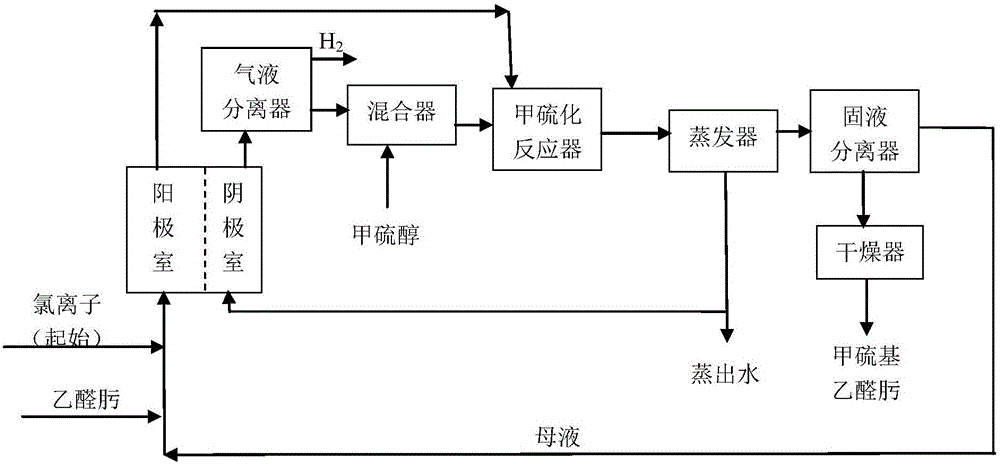

[0038] Such as figure 1As shown, a clean production system of methylthioacetaldoxime includes an electrolytic cell, a mixer, a methyl sulfide reactor, an evaporator, a solid-liquid separator, and a dryer connected in sequence, and the electrolytic cell is separated by a cation exchange membrane. In the anode chamber and the cathode chamber, cations can freely pass through the cation exchange membrane, but anions cannot pass through the exchange membrane, so that the cations in the anode chamber can enter the cathode chamber and combine with the hydroxide ions in the cathode chamber to form an alkaline solution, which is convenient for the subsequent preparation of formazan Sodium mercaptide, the liquid outlet of the anode chamber of the electrolytic cell is connected to the liquid inlet of the methyl sulfide reactor, the liquid outlet of the cathodic chamber of the electrolytic cell is connected to the liquid inlet of the mixer, and the liquid outlet of the mixer is connected t...

Embodiment 2

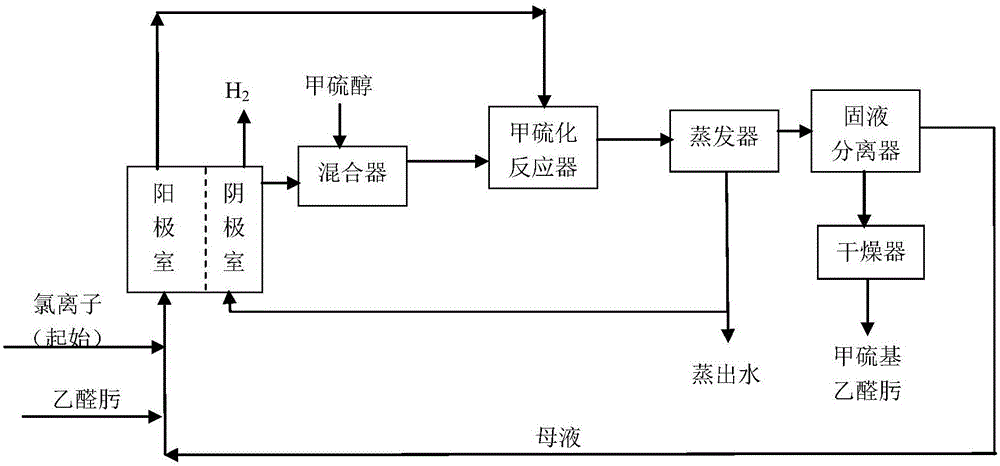

[0053] The production system of this embodiment is as figure 2 As shown, the rest of the devices are the same as in Example 1, only the cathode chamber of the electrolyzer has a separate liquid outlet and gas outlet, and the cathode chamber liquid outlet is connected to the liquid inlet of the mixer through a pipeline, so that the alkaline solution of the cathode flows into the mixer , after adding methyl mercaptan in the mixer, sodium hydroxide reacts with methyl mercaptan to make sodium methyl mercaptide, which enters the methyl sulfide reactor, and the liquid outlet of the anode chamber is connected to the liquid inlet of the methyl sulfide reactor, so that chlorine Reaction of acetaldehyde oxime with sodium methyl mercaptide to prepare methyl thio acetaldehyde oxime. The gas generated in the cathode chamber flows out from the gas outlet, and can be collected and purified for use as other raw materials.

[0054] Specifically, 20wt% sodium chloride aqueous solution and 25w...

Embodiment 3

[0056] The flow chart of the device is the same as in Example 2. Add 12wt% potassium chloride aqueous solution and 30wt% acetaldehyde oxime to the anode chamber respectively, and add 6wt% potassium chloride aqueous solution to the cathode chamber, and the molar ratio of acetaldehyde oxime to methyl mercaptan is 1:1.05; The cell voltage is 3.8V, and the current density of the anode and cathode is 3200A / m 2 The electrolysis temperature is 45°C; the yield of methylthio acetaldoxime is 94.3% (calculated as acetaldehyde oxime), the product purity reaches 98.0%, and the salt content of waste water is 0.05wt%. The electricity consumption for producing methylthioacetaldoxime is 2900kWh / t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power consumption | aaaaa | aaaaa |

| Power consumption | aaaaa | aaaaa |

| Power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com