Energy-saving system and technique for recovering aluminum ions and sulfuric acid in oxidation tank and shortening oxidation electrode distance

An oxidation tank and aluminum ion technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., to achieve the effects of shortening oxidation time, reducing oxidation energy consumption, and reducing the amount of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

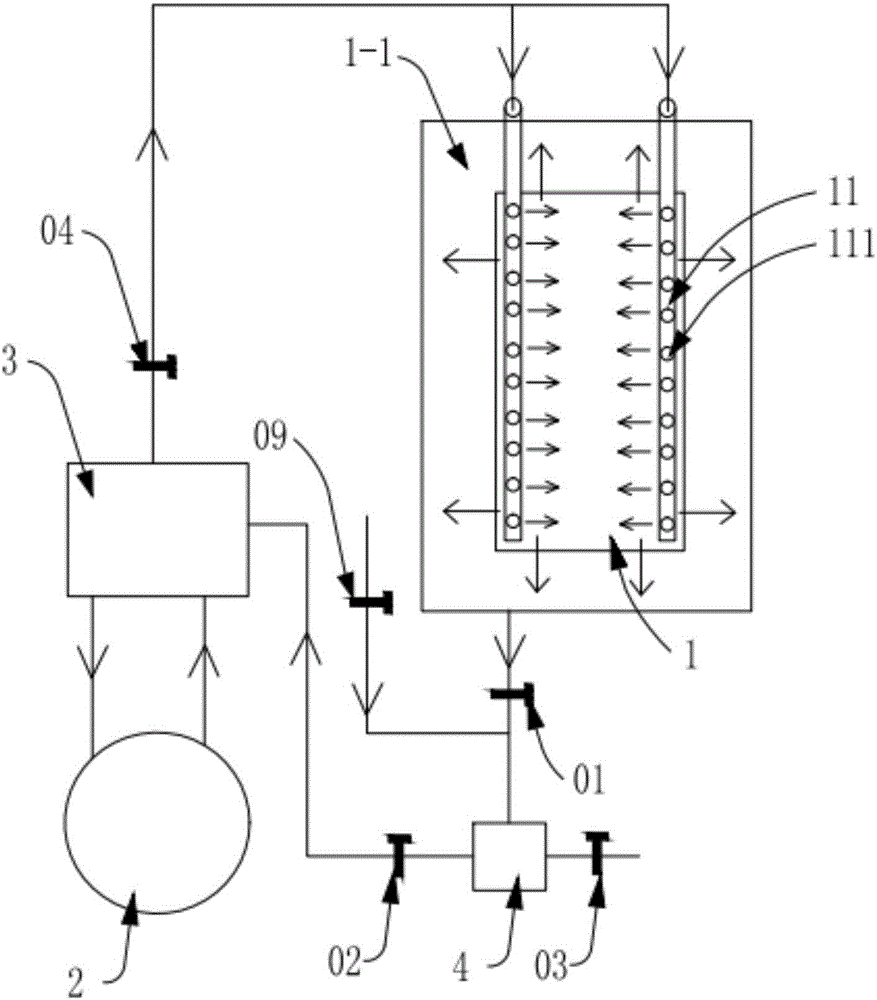

[0175] Embodiment 1 (anodizing solution cooling)

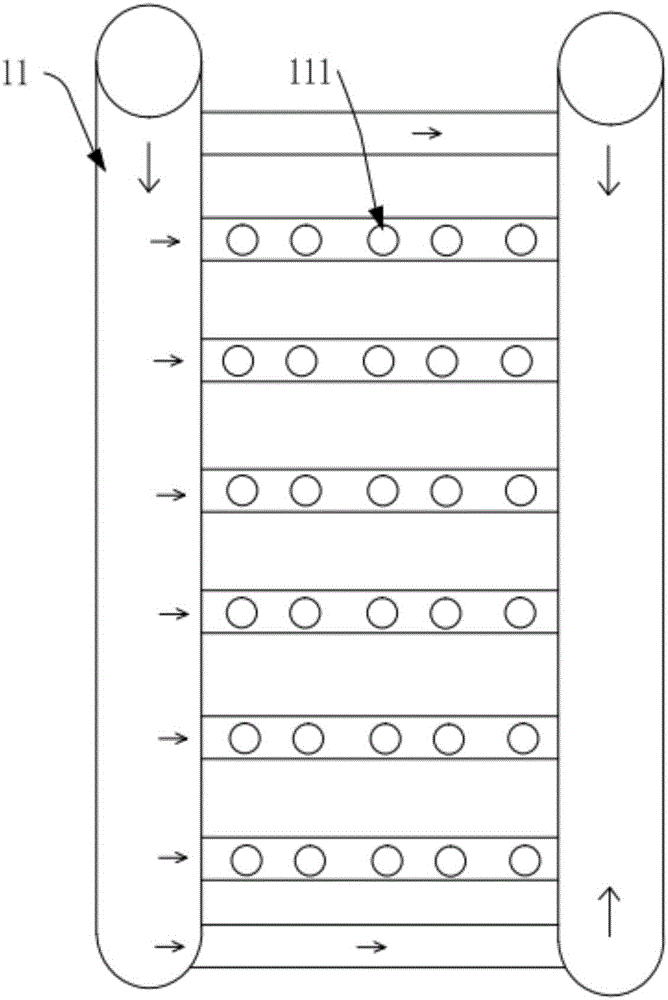

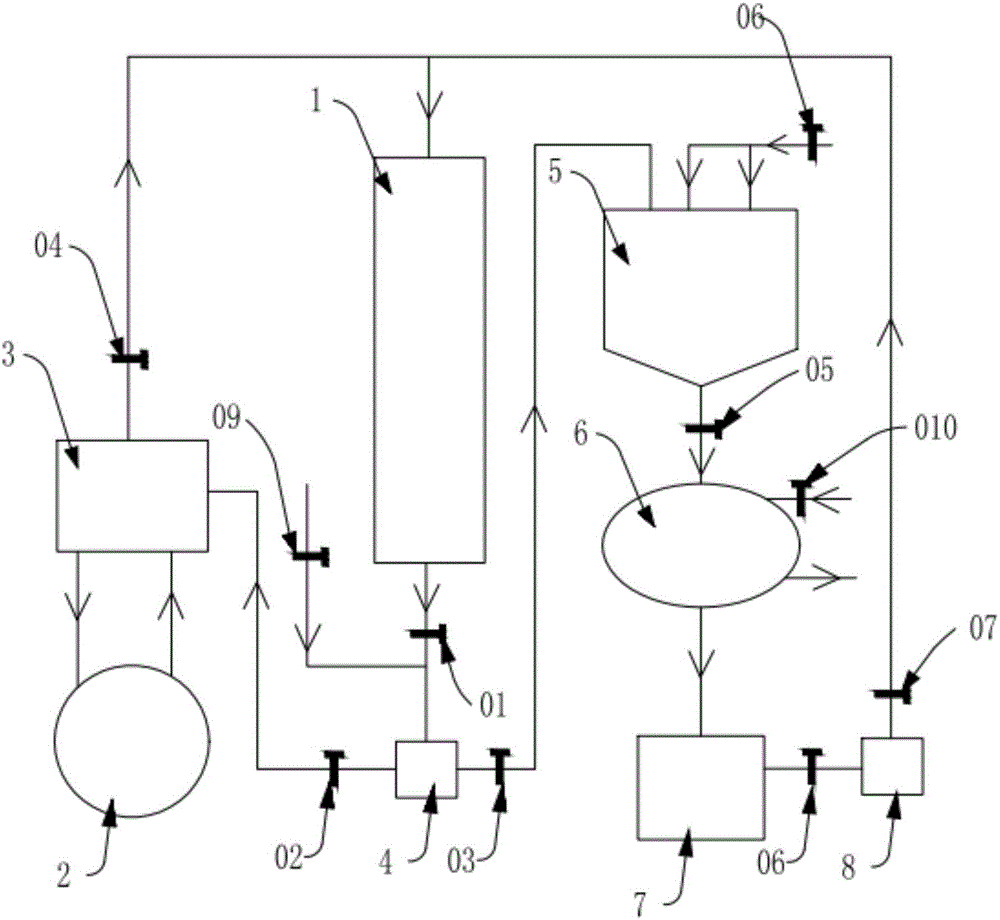

[0176] Close No. 3 valve 03, No. 9 valve 09, open No. 1 valve 01, No. 2 valve 02, No. 4 valve 04, No. 1 pump 4 and refrigerator 2, the oxidizing liquid cooled by refrigerator 2, from No. 4 valve 04 Enter the moving cathode cooling tube 11, blow directly to the surface of the aluminum alloy through the micropores of the moving cathode cooling tube 11, and quickly bring the oxidation heat at the interface of the oxide film into the oxidizing solution; the oxidizing solution carrying these heat overflows to the overflow tank 1- 1. Then, through No. 1 valve 01, No. 1 pump 4, and No. 2 valve 02, it enters the titanium exchanger 3 for refrigeration, and then passes through No. 4 valve 04 to circulate into the mobile cathode cooling pipe 11 to complete the oxidizing liquid cooling cycle.

Embodiment 2

[0177] Embodiment 2 (on-line recovery aluminum ammonium sulfate)

[0178] 1. Open No. 3 valve 03, close No. 2 valve 02, No. 9 valve 09, and turn 30M 3 After the oxidizing solution is pumped into the reaction tank 5, open the No. 2 valve 02, close the No. 3 valve 03; open the gas stirring No. 8 valve 08, and start stirring; add ammonium sulfate by 2.5 times the weight of the aluminum ion concentration, and stir while adding; After adding ammonium sulfate, continue to stir for 30 minutes and then close No. 8 valve 08, and leave standstill for 2 hours;

[0179] 2. Open the No. 5 valve 05, and the crystalline solid enters the centrifuge 6. Turn on the centrifuge 6 for solid-liquid separation; open the No. 10 valve 010 to repeatedly spray the solid in the centrifuge 6. When the pH value of the recovered liquid at the outlet of the centrifuge 6 is greater than 4.5, close the No. 10 valve 010 and stop spraying. Drench and centrifuge 6, reclaim aluminum ammonium sulfate by-product; ...

Embodiment 3

[0180] Embodiment 3 (on-line recovery oxidation solution)

[0181] Open the No. 6 valve 06, the No. 7 valve 07 and the No. 2 pump 8, and send the regenerated oxidation solution back to the oxidation tank 1 to complete the recovery of sulfuric acid;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com