A kind of low temperature on-line electrolytic phosphating solution

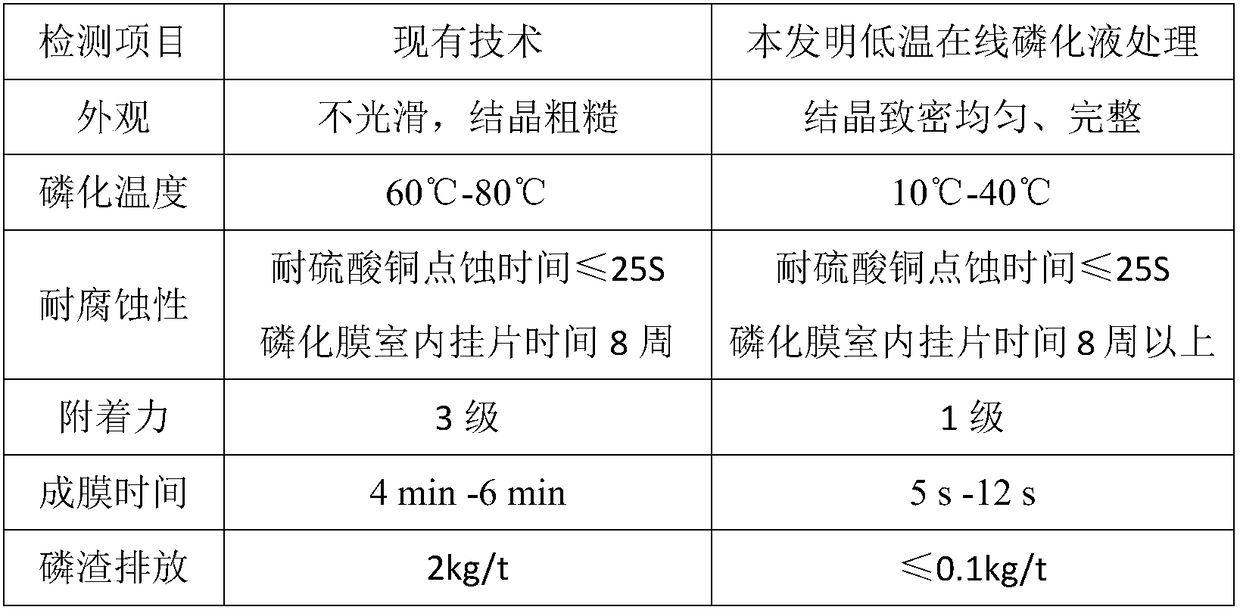

An electrolytic phosphating solution and low temperature technology, applied in phosphating and other directions, can solve the problems of long reaction time, high price, physical injury of operators, etc., and achieve short phosphating time, short film forming time and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A low-temperature online electrolytic phosphating solution, the low-temperature online electrolytic phosphating solution is a mixed solution composed of zinc oxide, phosphoric acid, nitric acid, nickel nitrate, citric acid and water, each component in the low-temperature online electrolytic phosphating solution The content is: zinc oxide 110g, phosphoric acid 160g, nitric acid 130g, nickel nitrate 1.5g, citric acid 1.5g, and the balance is water.

Embodiment 2

[0023] A low-temperature online electrolytic phosphating solution, the low-temperature online electrolytic phosphating solution is a mixed solution composed of zinc oxide, phosphoric acid, nitric acid, nickel nitrate, citric acid and water, each component in the low-temperature online electrolytic phosphating solution The content is: zinc oxide 90g, phosphoric acid 180g, nitric acid 110g, nickel nitrate 1.8g, citric acid 2g, and the balance is water. Wherein, the zinc oxide is an indirect zinc oxide with a purity of 99.7%; the phosphoric acid is a commercially available 85% phosphoric acid, and the nitric acid is a commercially available 68% phosphoric acid.

Embodiment 3

[0025] A low-temperature online electrolytic phosphating solution, the low-temperature online electrolytic phosphating solution is a mixed solution composed of zinc oxide, phosphoric acid, nitric acid, nickel nitrate, citric acid and water, each component in the low-temperature online electrolytic phosphating solution The content is: zinc oxide 75g, phosphoric acid 200g, nitric acid 100g, nickel nitrate 3g, citric acid 0.1g, and the balance is water. Wherein, the zinc oxide is an indirect zinc oxide with a purity of 99.7%; the phosphoric acid is a commercially available 85% phosphoric acid, and the nitric acid is a commercially available 68% phosphoric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com