Groove type solar heat collector

A trough-type solar energy and heat collector technology, which is applied in the direction of solar heat collectors, solar heat collector heat insulation, and solar heat collector working fluids. , the heat dissipation of the heat collector and other problems, to achieve the effect of saving cost and space, long service life, and overcoming harsh requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

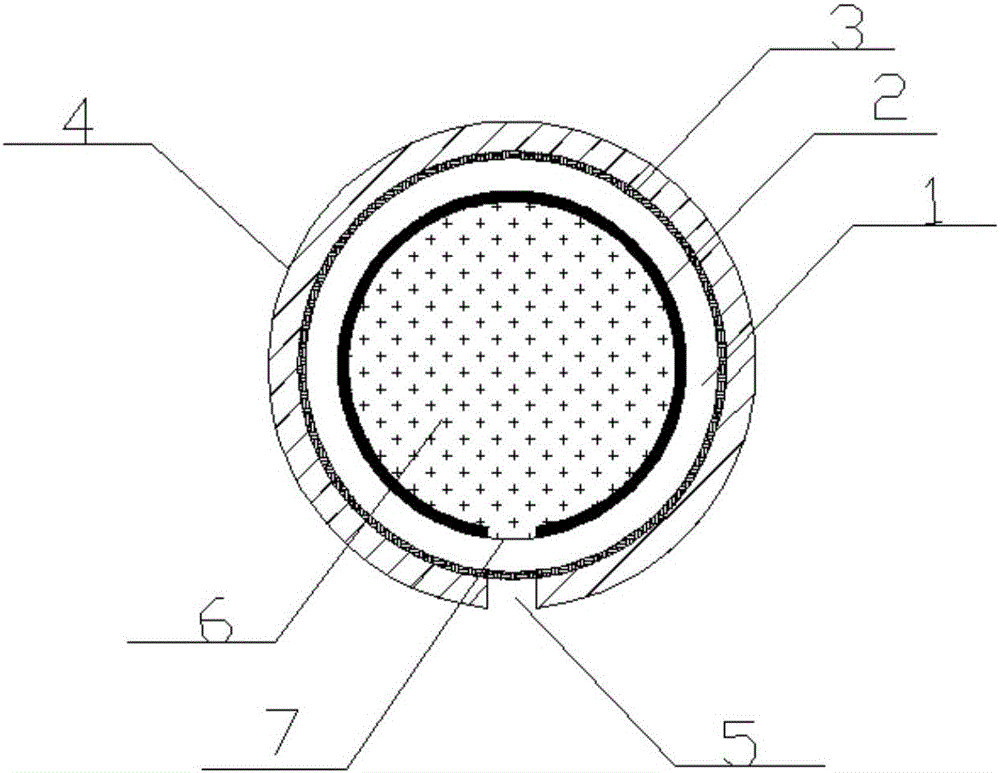

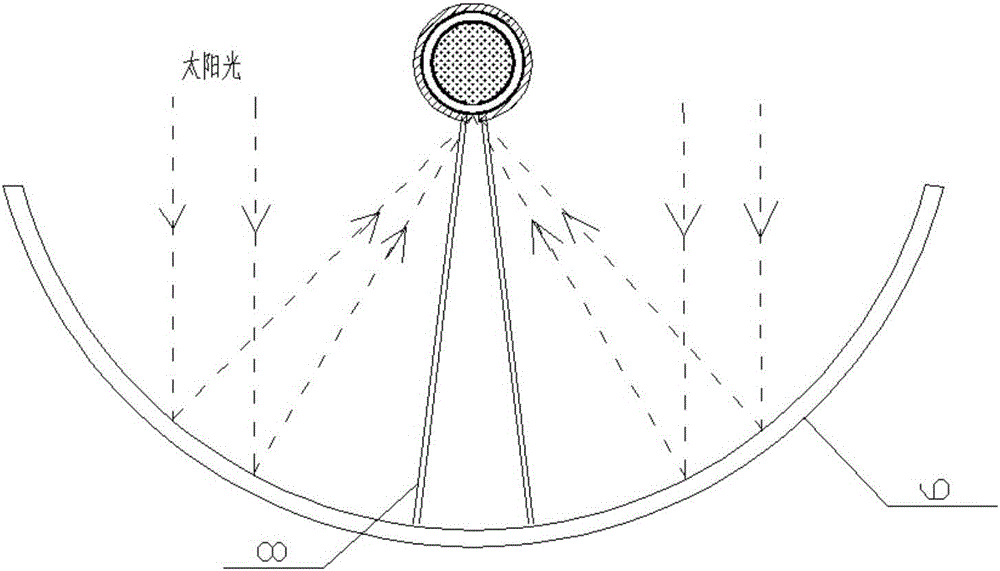

[0020] figure 1 What is shown is a schematic cross-sectional structure diagram of a heat collector of an embodiment of a trough solar heat collector disclosed in the present invention, and the heat collector includes a heat collecting tube, a concentrating paraboloid 9 and a support 7 . Wherein, the heat collecting tube includes a glass circular tube 1 , an absorbing coating 2 , a low-emissivity film 3 , an insulating layer 4 , an arc-shaped opening 5 of the insulating layer, and an arc-shaped opening 7 of the absorbing coating.

[0021] The glass tube 1 is made of high borosilicate glass with strong external impact resistance, and its linear thermal expansion coefficient is (3.3±0.1)×10-6 / K, which is a low expansion rate, high temperature resistance, high strength and high hardness. , special glass material with high light transmittance and high chemical stability. The inner surface of the glass tube 1 is attached with an absorbing coating 2, and the absorbing coating with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com