Microwave thermogravimetric analysis device and combined system

A thermogravimetric analysis and analysis system technology, which is applied in the direction of removing certain components and weighing, can solve the problems that the combination of analysis equipment is rarely involved, and achieve the effects of enriching material composition information, high degree of automation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

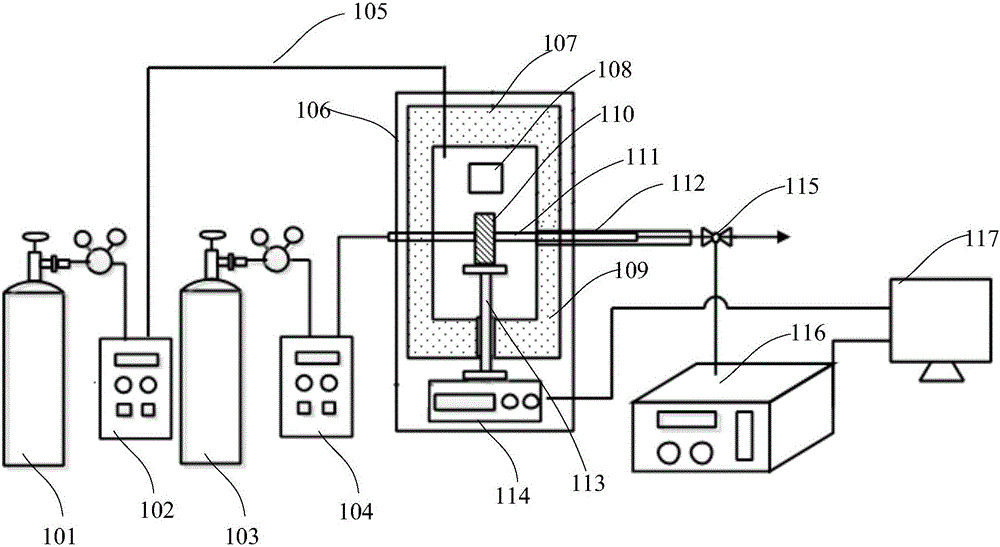

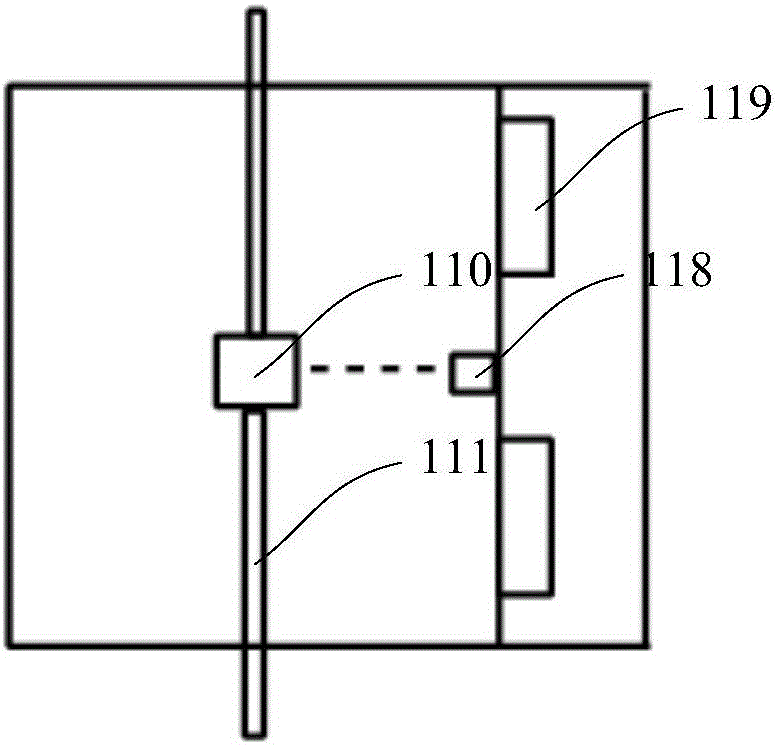

[0047] figure 1 It is a schematic structural diagram of the microwave thermogravimetric analysis device and the combined system of the present invention. figure 2 Shown is a top view of the microwave thermogravimetric analysis device used in the microwave thermogravimetric analysis device and the combined system of the present invention. Specifically, 101 is a protective gas cylinder, 102 is a gas flowmeter, 103 is a reaction gas cylinder, 104 is a gas flowmeter, 105 is a protective gas channel, 106 is the outer shell of the microwave resonance cavity, 107 is the microwave resonance cavity, 108 For the waveguide outlet, 109 is a high-temperature heat-resistant insulation material 109, 110 is a reactor (quartz reaction bottle), 111 is a reaction gas pipeline, 112 is an outlet pipe insulation tube, 113 is a support (quartz support), 114 is a precision electronic balance, 115 116 is a combined analysis system, 117 is a computer, 118 is an infrared thermometer, and 119 is a micr...

Embodiment 2

[0062] This embodiment provides a microwave thermogravimetric analysis device and a combined system, which uses microwave heating to conduct thermal analysis on materials, and uses an electronic balance 114 to record real-time mass changes in the heating process of materials, and at the same time conduct online analysis on the escaped gas during thermal analysis , to obtain more material composition information.

[0063] Specifically, the microwave thermogravimetric analysis device and the combined system include: a microwave generator 119 is installed on the back of the device, and microwaves are transmitted to the stainless steel microwave resonant cavity 107 through a waveguide. The waveguide outlet 108 is slightly higher than the center of the material, and adopts The quartz glass or polytetrafluoroethylene plate is connected and sealed with the stainless steel microwave resonant cavity 107 . The microwave input power is 0-5kW, controlled by PLC, the microwave output power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com