Preparation method of deposited cspbbr3 nanosheet thin film photodetector

A technology of photodetectors and nanosheets, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of unsuitable large-area preparation of thin films and limited volume of centrifuge tubes, so as to ensure large-area uniformity and compactness, The method is flexible and controllable, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

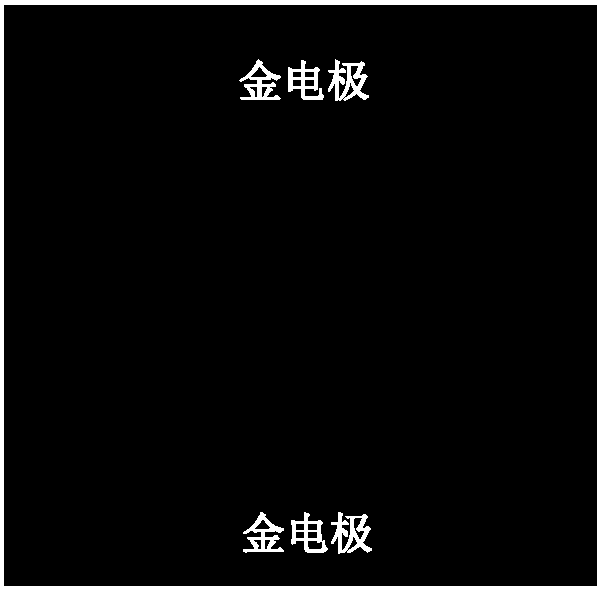

[0029] 1) Prepare patterned gold interdigitated electrodes with a pitch of 25 microns on the silicon substrate by photolithography, such as figure 1 shown;

[0030] 2) CsPbBr with a concentration of 10mg / mL 3 The nanosheet octadecene solution was centrifuged twice at 500 rpm, and finally dispersed into n-hexane to obtain CsPbBr 3 Nanosheet n-hexane dispersion, for later use;

[0031] 3) Put the container on the shock-absorbing table, then arrange 10 pieces of gold interdigitated electrodes in a circular beaker with a diameter of 2.2cm, and add 2mL of 0.05g / mL CsPbBr 3 Nanosheet n-hexane dispersion;

[0032] 4) Place the container open and keep it at 25°C until the n-hexane is completely evaporated to obtain deposited CsPbBr 3 Gold interdigitated electrodes of nanosheets;

[0033] 5) will deposit CsPbBr 3 The gold interdigitated electrode of the nanosheet is transferred to a hot stage at 90°C in air, and thermally annealed for 0.5h to obtain a chip;

[0034] 6) Connect t...

Embodiment 2

[0036] 1) Prepare patterned gold interdigitated electrodes with a spacing of 25 microns on a glass sheet by photolithography, such as figure 1 shown;

[0037] 2) CsPbBr with a concentration of 10mg / mL 3 The nanosheet octadecene solution was centrifuged at 1000rpm for 3 times, and finally dispersed in toluene to obtain CsPbBr 3 Nanosheet toluene dispersion, for subsequent use;

[0038] 3) Put the container on the shock-absorbing table, then arrange 10 pieces of gold interdigitated electrodes in a circular beaker with a diameter of 2.2cm, and add 2mL of 0.1g / mL CsPbBr 3 Nanosheet toluene dispersion;

[0039] 4) Place the container open, at 30°C until the toluene is completely evaporated, and deposit CsPbBr 3 Gold interdigitated electrodes of nanosheets;

[0040] 5) will deposit CsPbBr 3 The gold interdigitated electrode of the nanosheet is transferred to a hot stage at 50°C in air, and thermally annealed for 1 hour to obtain a chip;

[0041]6) Connect the prepared chip to...

Embodiment 3

[0043] 1) Prepare patterned gold interdigitated electrodes with a spacing of 25 microns on a quartz glass sheet by photolithography, such as figure 1 shown;

[0044] 2) CsPbBr with a concentration of 10mg / mL 3 The nanosheet octadecene solution was centrifuged at 2000 rpm for 4 times, and finally dispersed in chloroform to obtain CsPbBr 3 Nanosheet chloroform dispersion, for subsequent use;

[0045] 3) Put the container on the shock-absorbing table, then arrange 10 pieces of gold interdigitated electrodes in a circular beaker with a diameter of 2.2cm, and add 5mL of 0.02g / mL CsPbBr 3 Nanosheet chloroform dispersion;

[0046] 4) Place the container open and keep it at 40°C until the chloroform is completely evaporated to obtain deposited CsPbBr 3 Gold interdigitated electrodes of nanosheets;

[0047] 5) will deposit CsPbBr 3 The gold interdigitated electrode of the nanosheet was transferred to a hot stage at 150°C in the air, and thermally annealed for 0.5h to obtain a chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com