Deep ultraviolet LED packaging device and preparation method thereof

A technology of LED packaging and deep ultraviolet, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as aging, short service life, and complex packaging structure, so as to prevent the aging of intermediate insulating layer materials, improve reliability and The effect of service life and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

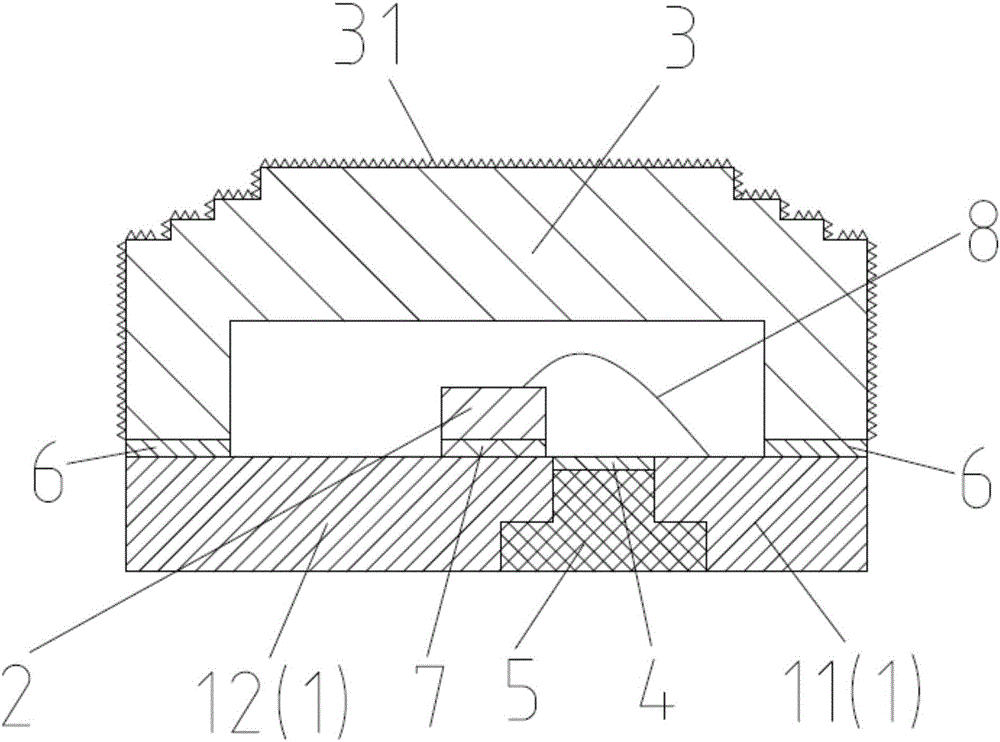

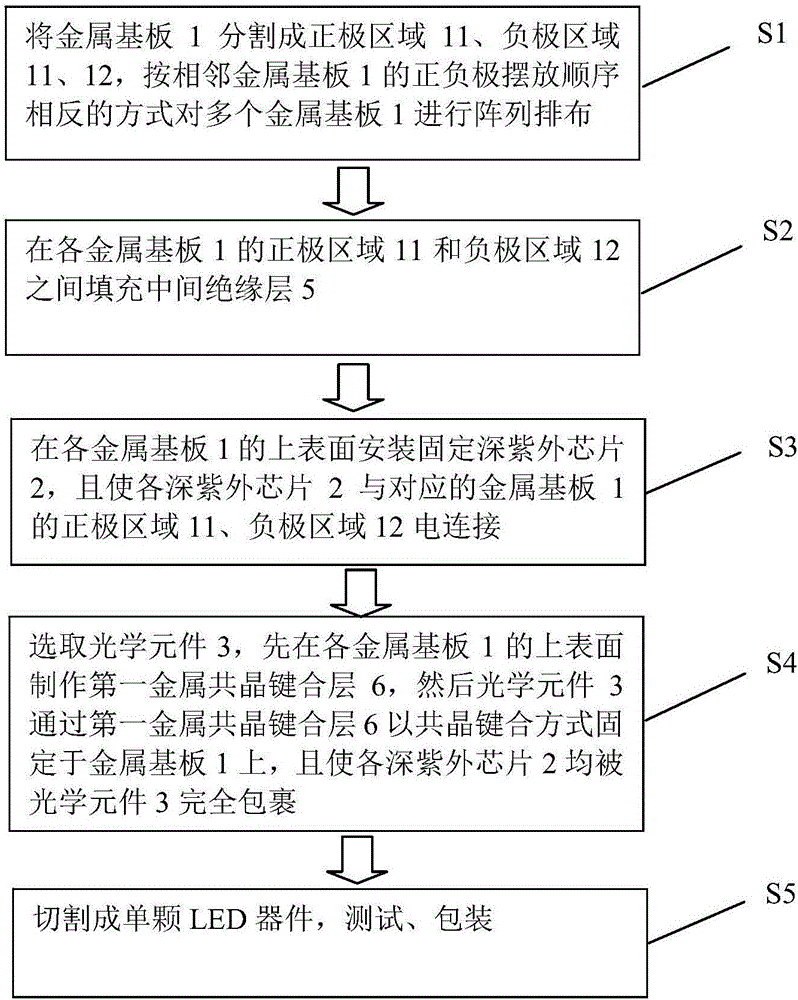

[0038] This embodiment discloses a deep ultraviolet LED packaging device, such as figure 1 As shown, it includes a metal substrate 1 , a deep ultraviolet chip 2 , an optical element 3 , an intermediate insulating layer 5 and a first metal eutectic bonding layer 6 .

[0039] Wherein, the positive electrode region 11 and the negative electrode region 12 of the metal substrate 1 are separated by the intermediate insulating layer 5; the deep ultraviolet chip 2 is fixed on the metal substrate 1, and the deep ultraviolet chip 2 is electrically connected with the positive electrode region 11 and the negative electrode region 12 of the metal substrate 1 .

[0040] Wherein, the optical element 3 is fixed on the metal substrate 1 through the first metal eutectic bonding layer 6 , and the optical element 3 completely wraps the deep ultraviolet chip 2 . In other words, in the present invention, the optical element 3 and the metal substrate 1 are combined by the metal eutectic bonding met...

Embodiment 2

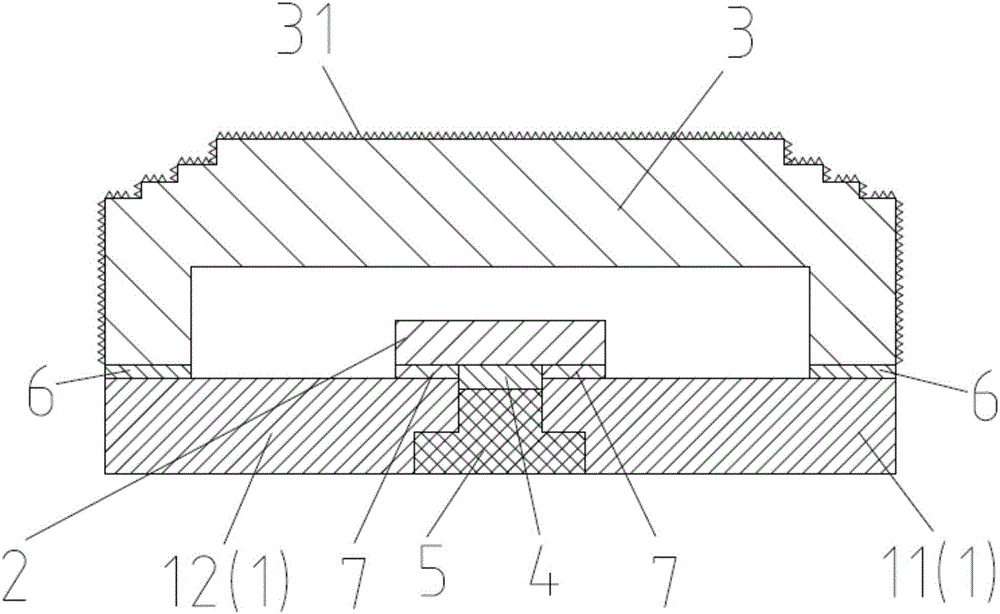

[0070] This embodiment discloses another deep-ultraviolet LED packaging device. In terms of structure, the difference between it and the deep-ultraviolet LED packaging device described in Embodiment 1 lies in:

[0071] Such as figure 2 As shown, the deep ultraviolet chip 2 is a flip chip, and the positive electrode region 11 and the negative electrode region 12 of the metal substrate 1 are provided with a second metal eutectic bonding layer 7, and the deep ultraviolet chip 2 (specifically, a flip chip) passes through the second metal eutectic bonding layer 7. The metal eutectic bonding layer 7 is electrically connected to the positive electrode region 11 and the negative electrode region 12 of the metal substrate 1 .

[0072] For the preparation method of deep ultraviolet LED packaging device, the difference between this embodiment and embodiment 1 lies in:

[0073] In step S4, the DUV chip 2 is selected as a flip chip, and the positive electrode region 11 and the negative e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com