A power grid peak regulation system and method for induction furnace iron bath coal gasification

A technology of induction furnace and coal gasification, which is applied in the direction of power network operating system integration, gasification process, AC network voltage adjustment, etc., and can solve the problems of electrolytic aluminum technology pollution and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

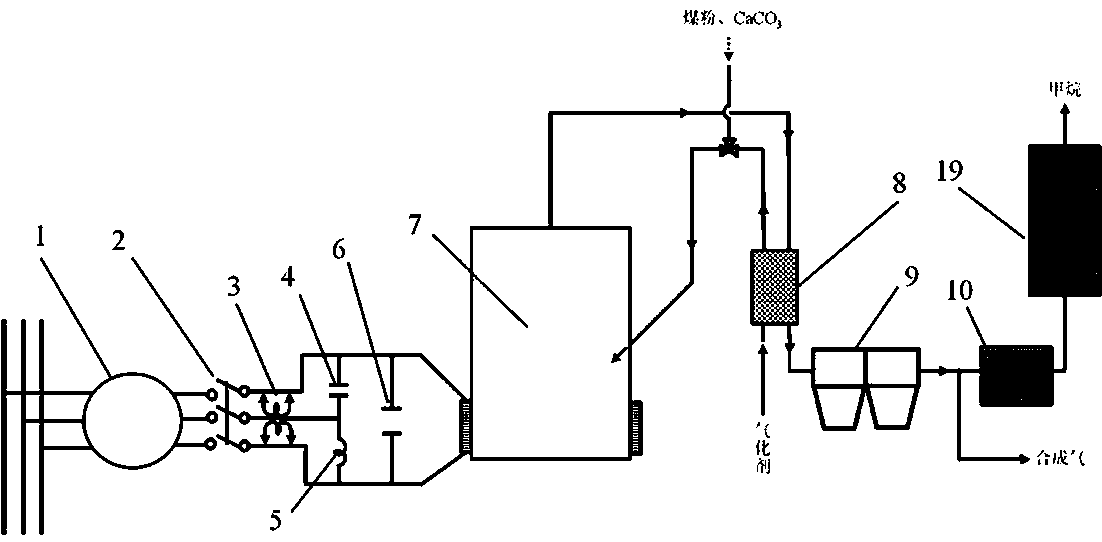

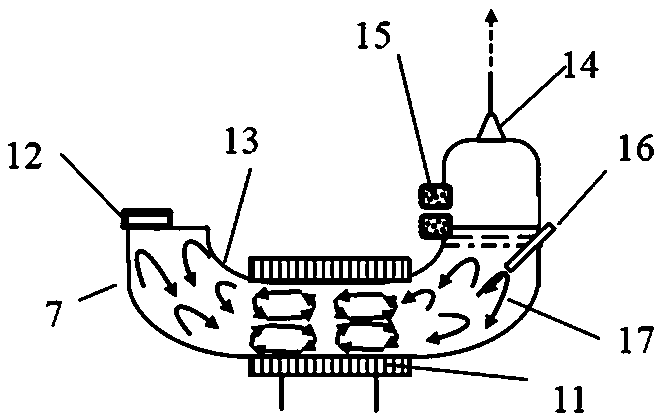

[0096] A power grid peak-shaving method for induction furnace iron-bath coal gasification is to adopt such figure 1 The power grid peak regulation system shown, the system adopts such as figure 2 The horizontal induction furnace shown: the furnace body is a U-shaped structure, the inner diameter of the horizontal part of the crucible is 1.5m, and the length is 2m; the inner diameter of the vertical part of the crucible is 2m, and the height is 3m; the power grid peak regulation method includes the following steps:

[0097] (1) According to the actual power consumption in the off-peak period, determine the peak-shaving amount of the power grid and set the power load;

[0098] (2) Put scrap iron / scrap steel into the induction furnace, and introduce electric energy into the induction furnace to heat and melt the scrap iron / scrap steel until the temperature reaches 1450°C and remains constant, the liquid level of molten iron is 2m high, and the mass is 76t;

[0099] (3) The gasi...

Embodiment 2

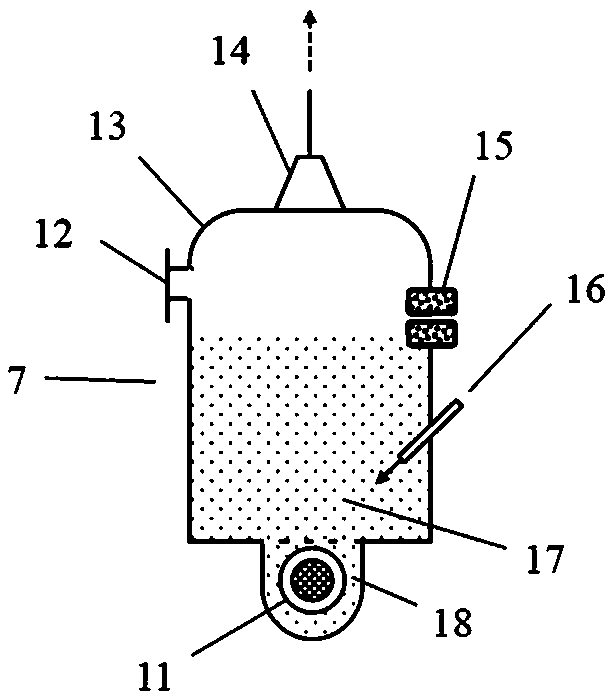

[0104] A power grid peak-shaving method for induction furnace iron-bath coal gasification is to adopt such figure 1 The power grid peak regulation system shown, the system adopts such as image 3 The shown groove type induction furnace: the furnace body is a cylindrical crucible, the diameter of the crucible is 2.16m, and the height is 4m; the power grid peak regulation method includes the following steps:

[0105] (1) According to the actual power consumption in the off-peak period, determine the peak-shaving amount of the power grid and set the power load;

[0106] (2) Put scrap iron / scrap steel into the induction furnace, and introduce electric energy into the induction furnace to heat and melt the scrap iron / scrap steel until the temperature reaches 1400°C and remains constant, the liquid level of molten iron is 3m high, and the mass is 86t;

[0107] (3) Preheat the steam of the gasification agent to 400°C, spray the mixed powder of coal powder and calcium carbonate carri...

Embodiment 3

[0112] A power grid peak-shaving method for induction furnace iron-bath coal gasification is to adopt such figure 1 The multiple sets of power grid peak regulation systems shown, the multiple sets of systems adopt such as figure 2 The horizontal induction furnace shown: the furnace body is a U-shaped structure, the inner diameter of the horizontal part of the crucible is 1.5m, and the length is 2m; the inner diameter of the vertical part of the crucible is 2m, and the height is 3m; the power grid peak regulation method includes the following steps:

[0113] (1) Determine the peaking amount of the power grid according to the actual power consumption in the off-peak period, set the power load, and connect multiple sets of power grid peaking systems in parallel;

[0114] (2) Put scrap iron / scrap steel into the induction furnace, and introduce electric energy into the parallel induction furnace through the power supply device to heat and melt the scrap iron / scrap steel until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com