Nanometer composite multilayer phase-change film and preparation method and application thereof

A nano-composite and thin-film technology, applied in the field of microelectronic materials, can solve the problems of slow phase transition speed, low crystallization speed, and inability to meet, and achieve the effects of reducing operating power consumption, improving heating efficiency, and reducing thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Ge prepared in this implementation 50 Te 50 / Ge 8 Sb 92 Nanocomposite multilayer phase change film, the total thickness is about 50nm, the general structure is [Ge 50 Te 50 (a) / Ge 8 Sb 92 (b)] x , Where a is Ge in a single cycle 50 Te 50 The thickness of the film, b is Ge in a single cycle 8 Sb 92 The thickness of the film, x is the total period of the nanocomposite multilayer phase change film, the specific structure is [Ge 50 Te 50 (4nm) / Ge 8 Sb 92 (8nm)) 4 .

[0036] 1. Cleaning SiO 2 / Si(100) substrate surface and back, to remove dust particles, organic and inorganic impurities:

[0037] (a) Place the substrate in an ethanol solution and clean it with ultrasonic for 20 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0038] (b) Put the substrate in an acetone solution and clean it with ultrasonic for 20 minutes to remove organic impurities on the surface of the substrate;

[0039] (c) Put the substrate in deionized water, clean it ...

Embodiment 2

[0051] A nano-composite multilayer phase change film, the preparation method adopted is roughly the same as that of Example 1, except that the specific structure of the nano-composite multilayer phase change film prepared by this embodiment is [Ge 50 Te 50 (5nm) / Ge 8 Sb 92 (5nm)) 5 .

Embodiment 3

[0053] A nano-composite multilayer phase change film, the preparation method adopted is roughly the same as that of Example 1, except that the specific structure of the nano-composite multilayer phase change film prepared by this embodiment is [Ge 50 Te 50 (8nm) / Ge 8 Sb 92 (4nm)) 4 .

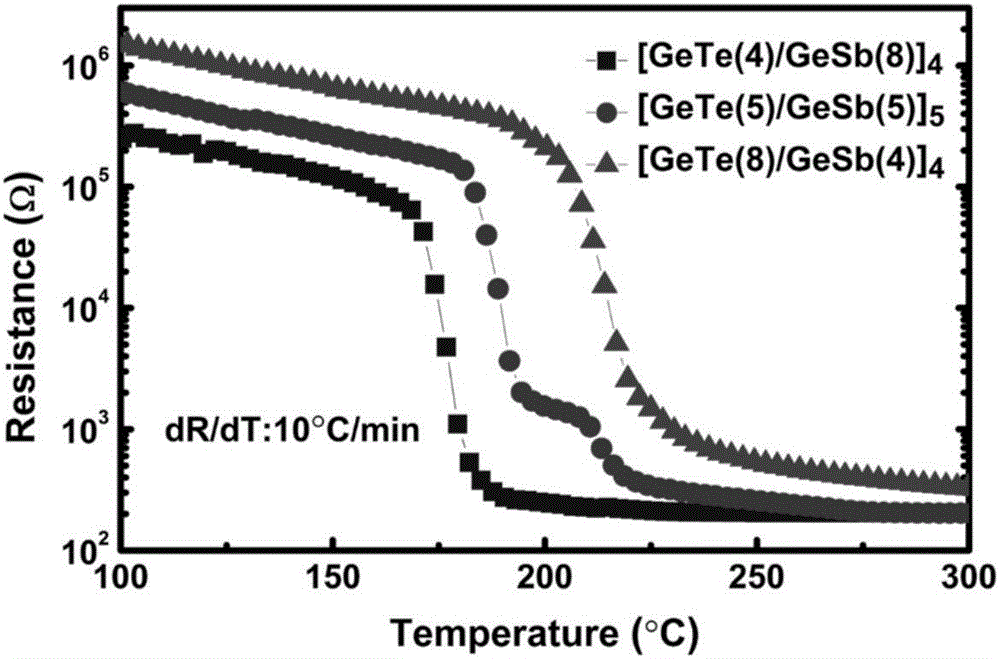

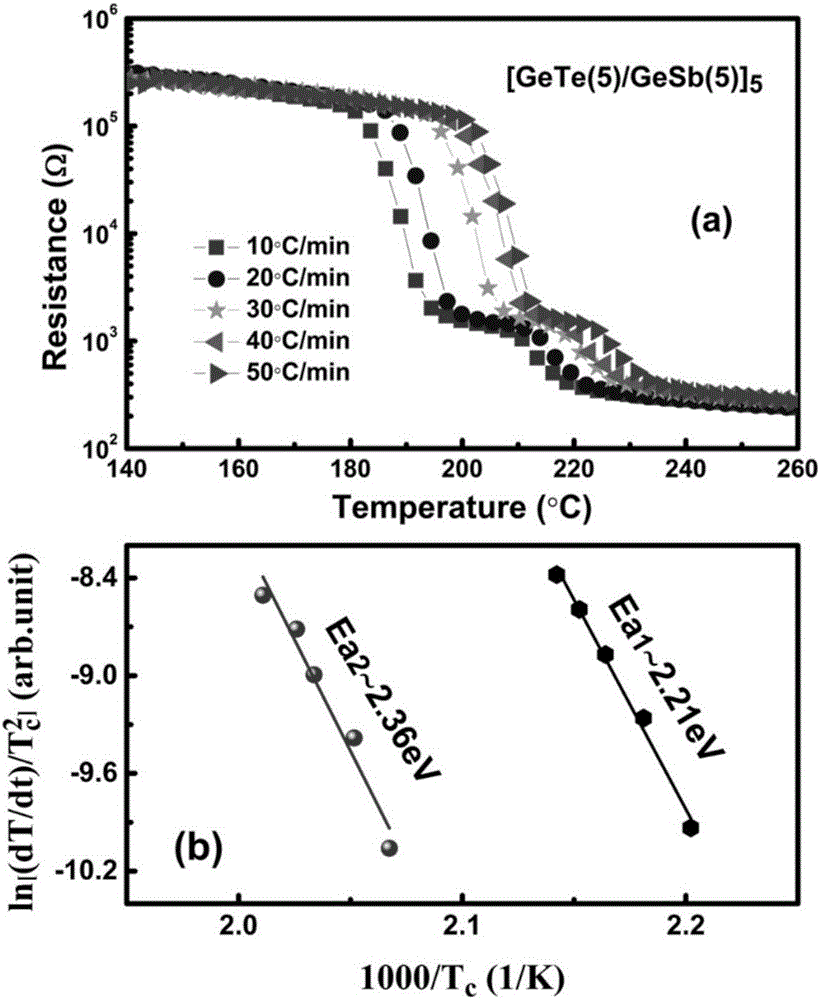

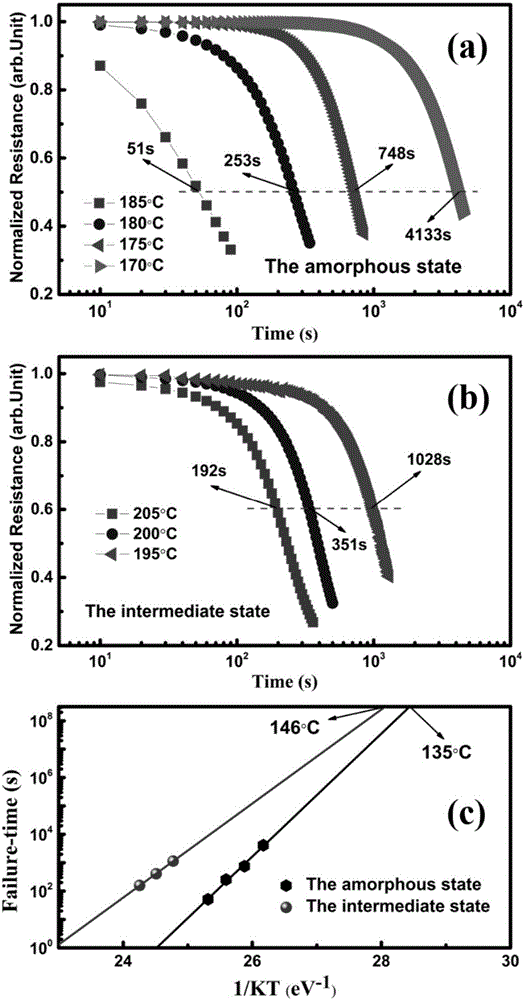

[0054] The Ge of the above embodiment 50 Te 50 / Ge 8 Sb 92 Nanocomposite multilayer phase change film materials are tested, and the in-situ resistance and temperature curves of each phase change film material are obtained, such as figure 1 Shown; the [Ge 50 Te 50 (5nm) / Ge 8 Sb 92 (5nm)) 5 The nanocomposite multilayer phase change film was tested, and the Kissinger equation was used to fit [Ge 50 Te 50 (5nm) / Ge 8 Sb 92 (5nm)) 5 The crystallization activation energy corresponding to the first phase transition and the second phase transition of the film, such as figure 2 Shown; the [Ge 50 Te 50 (5nm) / Ge 8 Sb 92 (5nm)) 5 The nanocomposite multilayer phase change film is tested, and the Arrhenius equation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com