Processing method of straw feed for promoting food intake of ruminant

A straw feed and ruminant technology, applied in the field of feed, can solve the problems of reduced nutritional value, reduced straw digestion and utilization rate, low feeding value, etc., and achieve the effect of increasing feed intake, improving palatability and digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

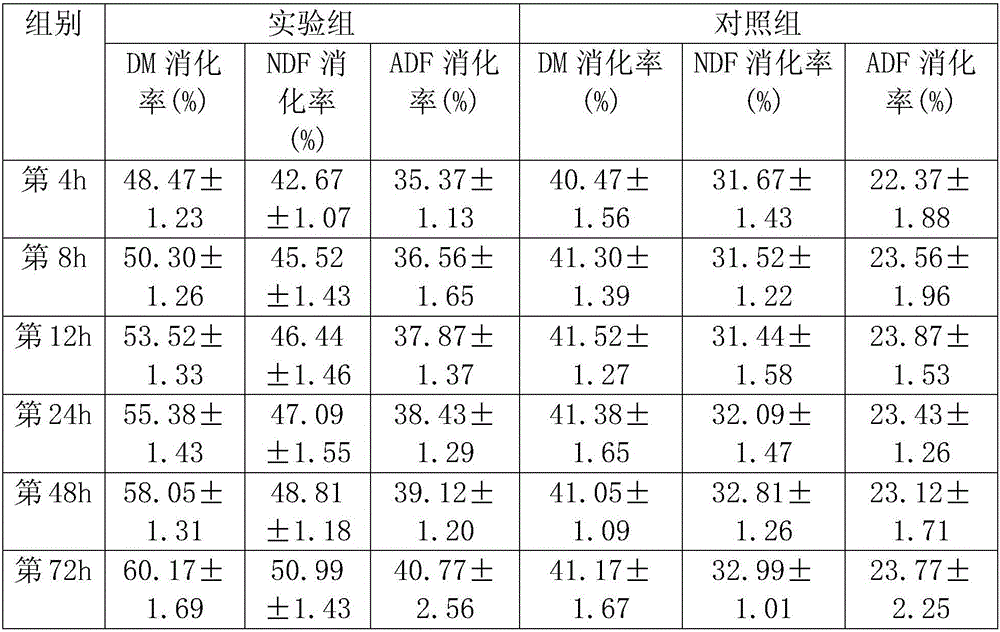

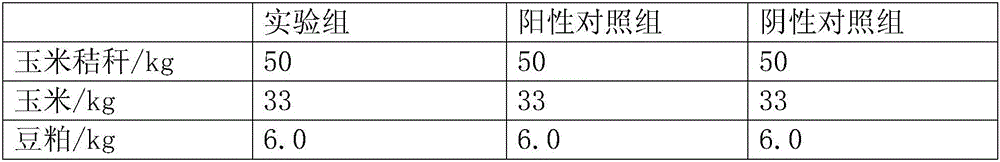

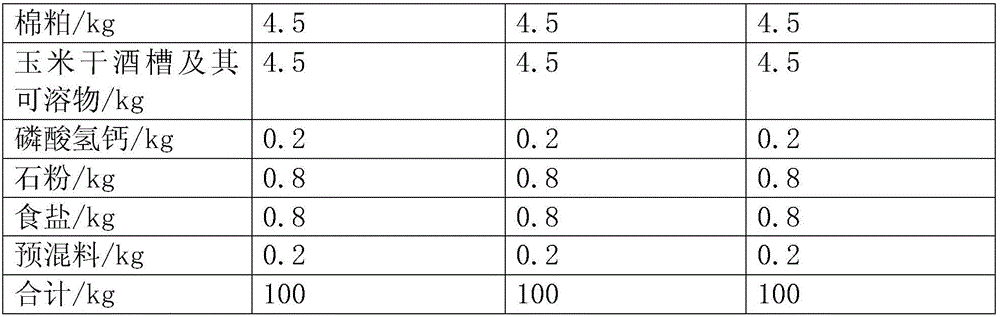

Examples

Embodiment 1

[0016] 1) crushing the straw to 20 mesh to obtain straw powder;

[0017] 2) Add a mixed solvent of ethanol, acetone and water to the straw powder, the volume ratio of ethanol, acetone and water is 10:1:1, the solid-liquid ratio of the straw powder to the mixed solvent is 1g:3ml, stir well, and use the dosage Co-60 gamma rays at a rate of 30 krad / min were irradiated for 2 minutes, ethanol and acetone were recovered under reduced pressure, and dried to obtain straw feed.

Embodiment 2

[0022] 1) crushing the straw to 100 mesh to obtain straw powder;

[0023] 2) Add a mixed solvent of ethanol, acetone and water to the straw powder, the volume ratio of ethanol, acetone and water is 3:1:1, the solid-liquid ratio of the straw powder to the mixed solvent is 1g:5ml, stir well, and use the dosage Co-60 gamma rays at a rate of 50krad / min were irradiated for 4 minutes, ethanol and acetone were recovered under reduced pressure, and dried to obtain straw feed.

Embodiment 3

[0025] 1) crushing the straw to 80 mesh to obtain straw powder;

[0026] 2) Add a mixed solvent of ethanol, acetone and water to the straw powder, the volume ratio of ethanol, acetone and water is 5:2:1.5, the solid-liquid ratio of the straw powder to the mixed solvent is 1g:4ml, stir well, and use the dosage Co-60 gamma rays at a rate of 40 krad / min were irradiated for 3 minutes, ethanol and acetone were recovered under reduced pressure, and dried to obtain straw feed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com