Method for preparing guava fruit powder by vacuum freeze drying

A technology of vacuum freeze-drying and guava, which is applied in the field of fruit powder preparation and vacuum freeze-drying to prepare guava fruit powder. It can solve the problems of not maintaining the hypoglycemic effect for a long time, lowering blood sugar, and lowering the blood sugar level of white mice, so as to meet consumption desires. , easy to rehydrate, and improve the effect of dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 7

[0049] Embodiment 1~Example 7, Comparative Examples 1~7

[0050] The fruit pulp was prepared according to the method of the embodiment, the drying aid shown in Table 2 was added to the filtered fruit pulp, and the drying aid was stirred rapidly to mix the fruit pulp and the drying aid evenly. In this specification, unless otherwise specified, "%" is mass percentage.

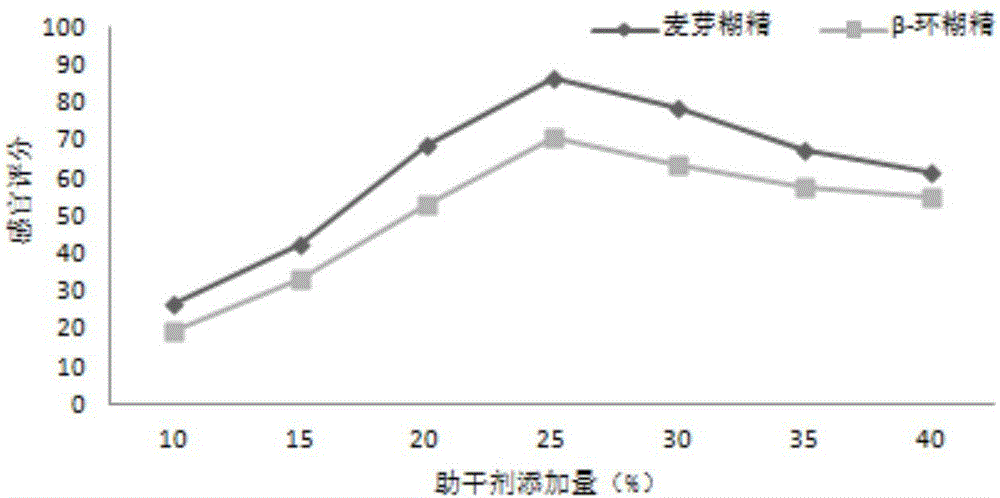

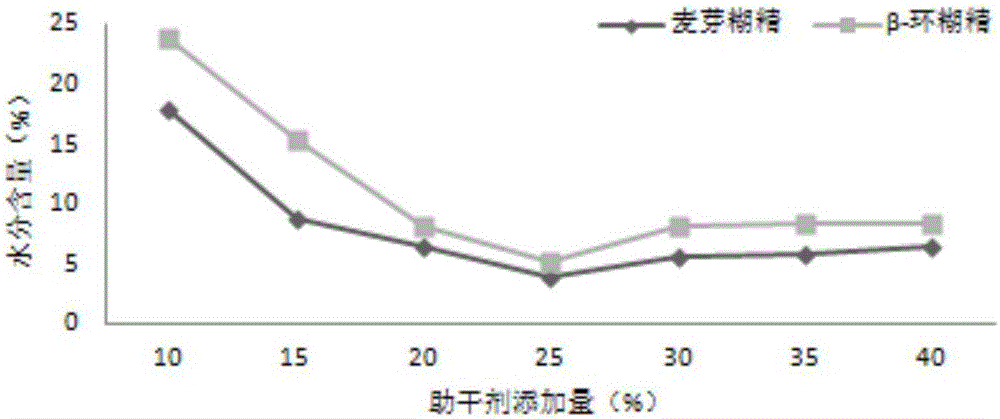

[0051] Table 2 Effects of different additions of different drying aids on the sensory evaluation of guava fruit powder

[0052] Example 1 2 3 4 5 6 7 Amount of drying aid added (%) 10 15 20 25 30 35 40 Maltodextrin 26.6 42.5 69.2 86.5 79.0 67.4 61.8 comparative example 1 2 3 4 5 6 7 Amount of drying aid added (%) 10 15 20 25 30 35 40 β-cyclodextrin 19.8 33.4 53.2 71.0 63.5 57.6 55.0

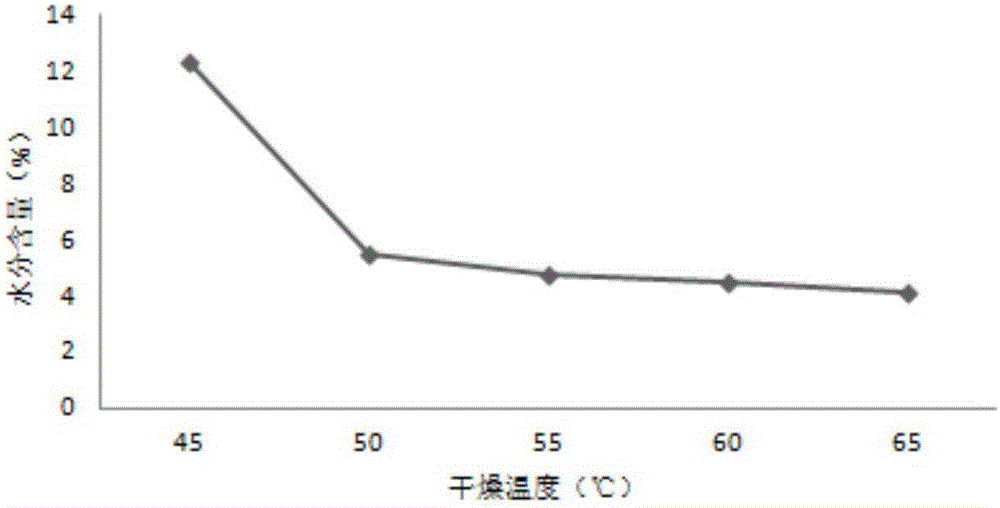

[0053] The uniformly mixed pulp has a thickness of 3 mm, and is pre-frozen at a low temperature, the pre-freezing temperature is -45°C, and the pre-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com