Crystal ice jelly and making method thereof

A technology of crystal ice powder and hot water, applied in the field of ice powder, which can solve the problems of non-degradability, damage to nutrients and taste, and poor visual effects, so as to reduce the load and help the formation of ice powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

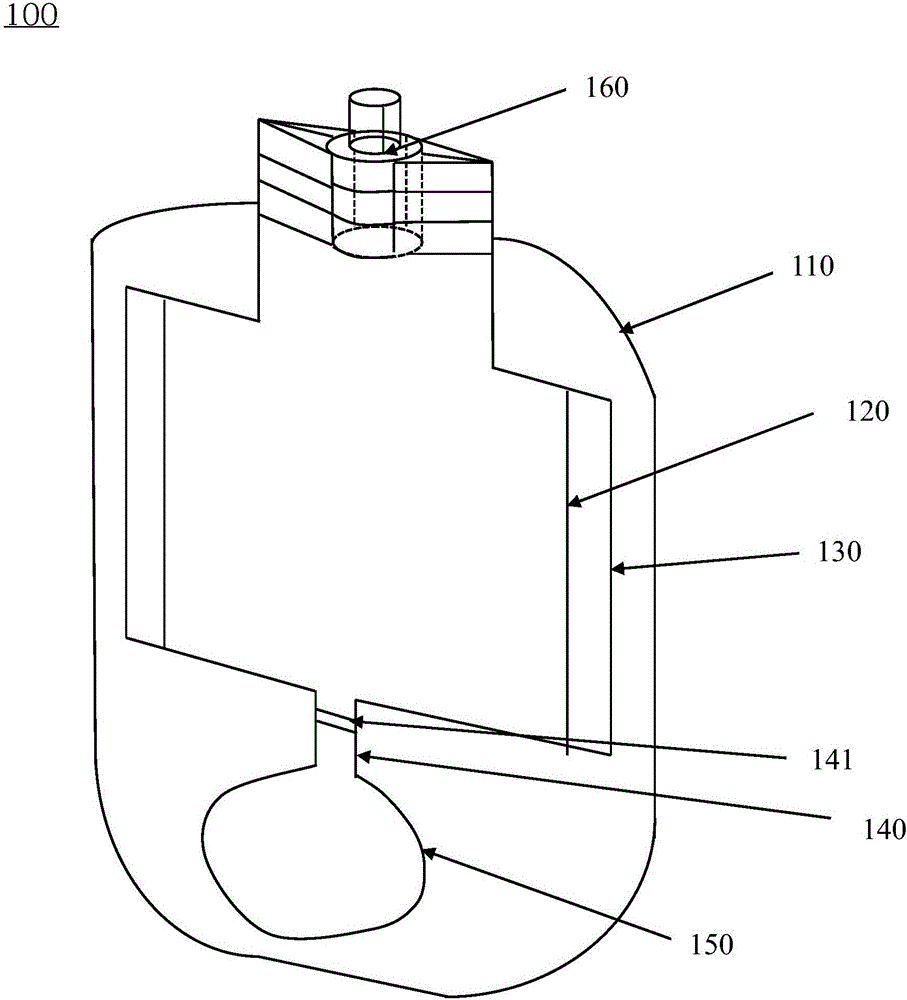

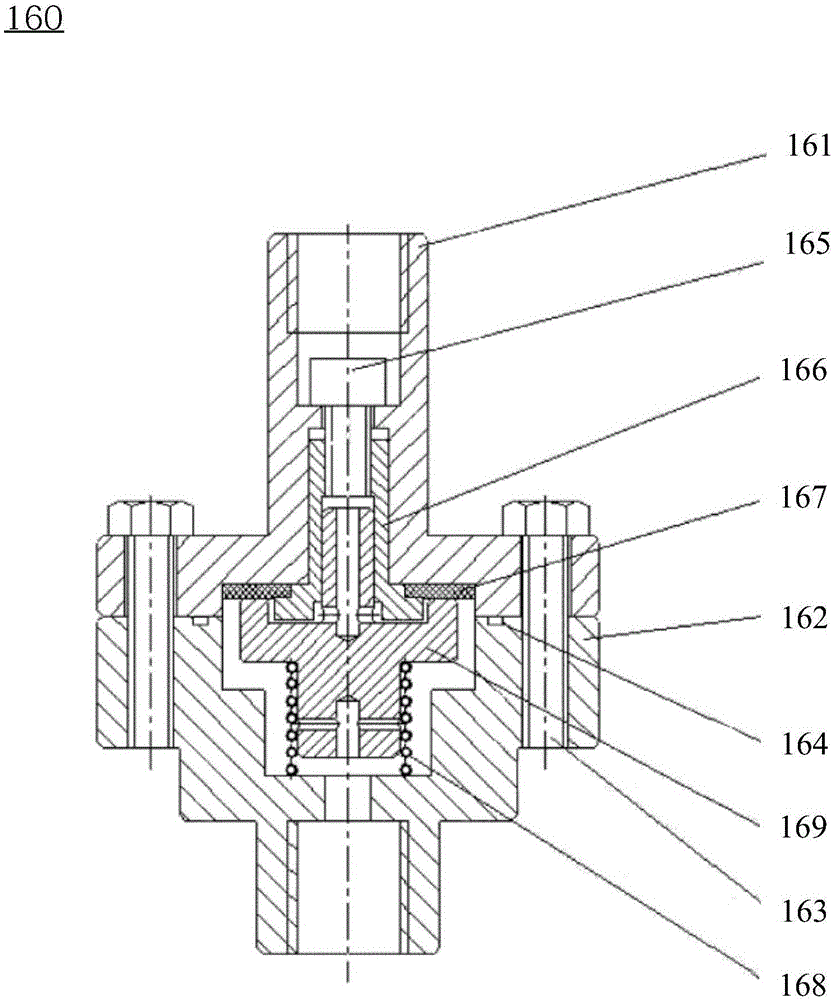

[0065] Another aspect of the present invention also provides a preparation method of crystal ice powder. This preparation method is as follows: introduce in the cavity of the inner layer container 120 of ice powder bag 100 by the hot water outlet 160 of the ice powder bag 100 that is stored with crystal ice powder powder and be 70~160 with crystal ice powder weight ratio: 1 for hot water. Squeeze the outer layer container 110 of the powdered ice bag 100 to transfer the pressure change caused by the contraction of the outer layer container 110 to the flexible powder bin 150 for storing the crystal ice powder. Furthermore, the crystal ice powder stored in the flexible powder bin 150 enters the cavity of the inner container 120 and mixes with hot water to make crystal ice powder. Preferably, the preparation method of crystal ice powder at least comprises the steps:

[0066] S1: Store crystal ice powder in the flexible powder bin 150 of the ice powder bag 100 .

[0067] S2: Int...

Embodiment 1

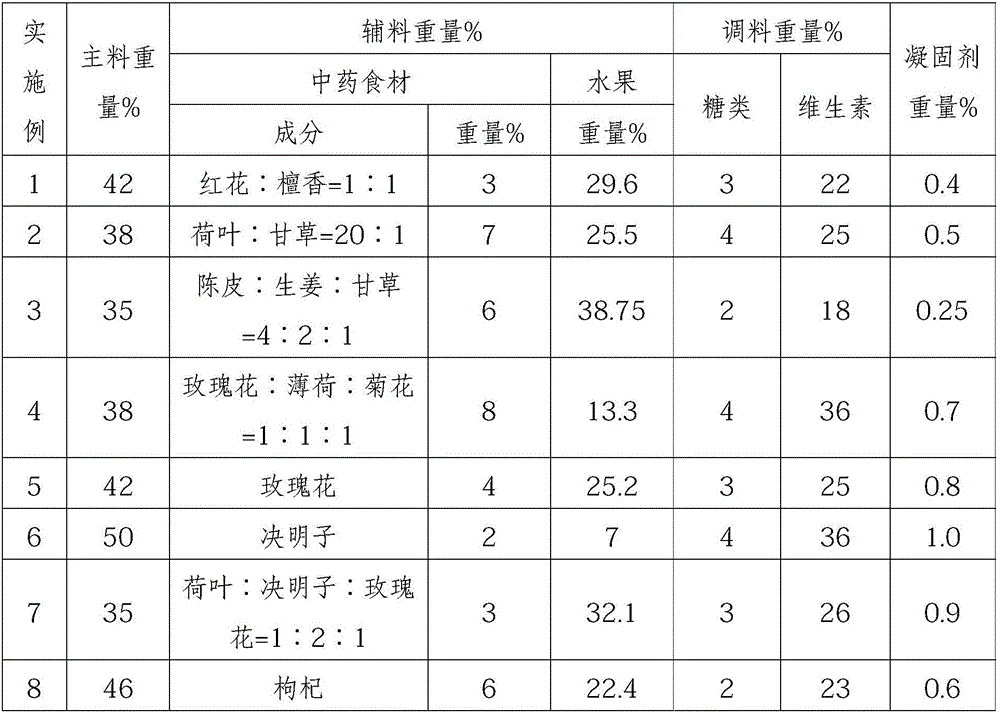

[0091]Weigh the main ingredients, auxiliary materials, spices and coagulant in Table 1. The present embodiment prepares crystal ice powder powder in the following manner:

[0092] S101: Add the main ingredient pseudophysalis seeds to pure water with a weight ratio of 1:1 to 10:1, put the purified water with pseudophysalis seeds into the ultra-high pressure treatment equipment, under the pressure of 700MPa, the temperature Keep for 3.5 minutes under low temperature and ultra-high pressure conditions below 10°C to obtain pseudophysalis seed extract. The pseudophysalis seed extract was filtered to obtain pseudophysalis.

[0093] S102: Add the auxiliary materials to the pure water with a weight ratio of 1:1 to 10:1, put the purified water with the auxiliary materials into the ultra-high pressure treatment equipment, and put them in a low-temperature ultra-high pressure with a pressure of 800 MPa and a temperature below 5°C Under the condition, keep it for 6.0min to obtain the ex...

Embodiment 2

[0104] Weigh the main ingredients, auxiliary materials, spices and coagulant in Table 1. Crystal ice powder and crystal ice powder are prepared by the same method as in Example 1, and the process conditions for preparation are shown in Table 2 and Table 3.

[0105] The crystal ice powder of this embodiment is crystal clear, cool, sweet, tender and refreshing, and can meet the needs of consumers with various physiques; the crystal ice powder of this embodiment is rich in nutrients, and the nutrients are easy to absorb and have a good taste; Crystal ice powder also has the functions of supplementing vitamin B6, clearing heat and relieving heat, diuresis and quenching thirst, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com