Composite air purifying and filtering structure and composite air purifying filter element

A technology of air purification and filtration structure, applied in the field of air purification, can solve the problems of limited HEPA filter removal function, filter clogging failure, etc., and achieve the effect of improving purification effect, improving adsorption performance, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

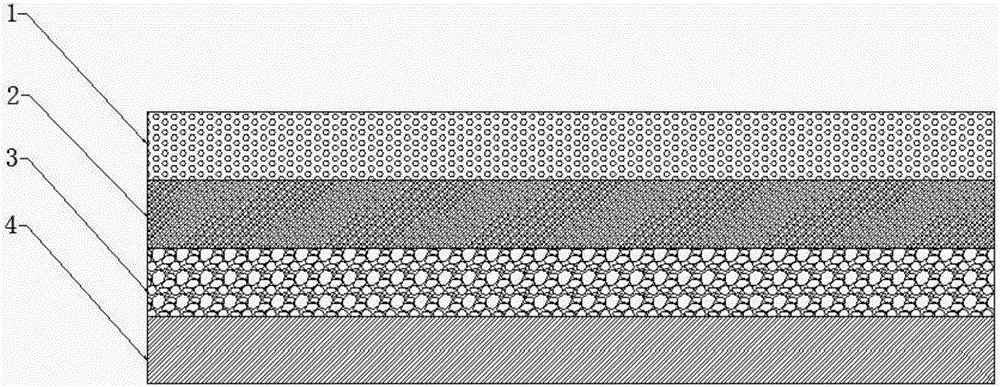

[0036] 1) According to the composite air purification filter structure of this embodiment (also referred to as "composite air purification filter paper") such as figure 1 shown.

[0037] 2) The preparation method of negative ion fiber filter layer 1 is that tourmaline powder with a certain mesh number of 6000 and PET non-woven masterbatch are blended and extruded on a twin-screw extruder, and the mass ratio of the added content of tourmaline powder is 2.0%. The obtained negative ion masterbatch is dried at 100 degrees Celsius, and finally processed into negative ion fibers by spinning.

[0038] 3) The particle filter layer 2 selects PP melt-blown filter paper with a filtration efficiency of 95%;

[0039] 4) Adsorption catalytic particle layer 3 is activated carbon supported metal oxide MnO x Mix the Mn precursor manganese nitrate solution with activated carbon, impregnate and stir, impregnate for 24 hours, and then bake at 300°C for 30 minutes to obtain catalyst particles for ...

Embodiment 2

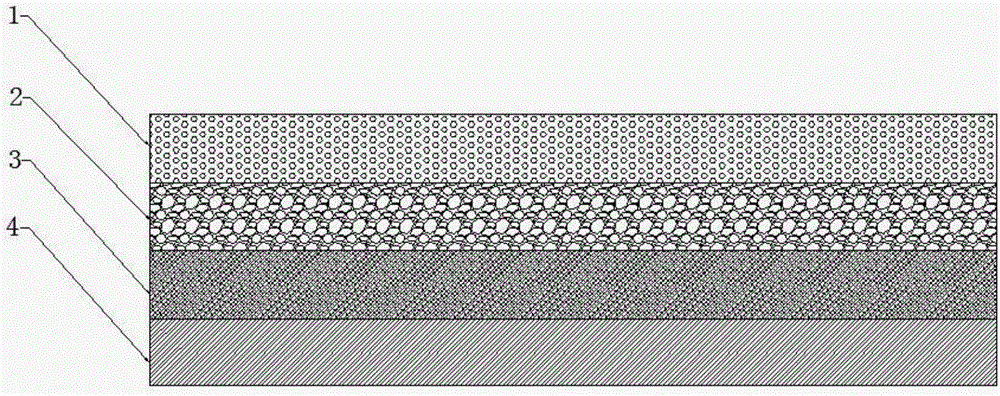

[0046] 1) According to the composite air purification filter structure of the present embodiment such as figure 2 shown.

[0047] 2) The preparation method of the negative ion fiber filter layer 1 is that tourmaline powder with a certain mesh number of 9000 and PET non-woven masterbatch are blended and extruded on a twin-screw extruder, and the mass ratio of the tourmaline powder is 3.0%. The anion masterbatch obtained is dried at 100 degrees Celsius, and finally spun into anion fibers.

[0048] 3) Adsorption catalytic particle layer 2 is activated carbon supported metal oxide MnO x Mix the Mn precursor manganese acetate tetrahydrate solution with activated carbon, impregnate and stir, impregnate for 24 hours, and then bake at 300°C for 30 minutes to obtain room temperature catalytic oxidation of formaldehyde catalyst particles, thus making adsorption catalytic particle layer 2 , wherein the activated carbon is selected to have a CTC adsorption rate of more than 60% and a p...

Embodiment 3

[0056] 1) According to the composite air purification filter structure of the present embodiment such as figure 1 shown.

[0057] 2) The preparation method of negative ion fiber filter layer 1 is that tourmaline powder with a certain mesh number of 6000 and PET non-woven masterbatch are blended and extruded on a twin-screw extruder, and the mass ratio of the added content of tourmaline powder is 2.0%. The anion masterbatch obtained is dried at 100 degrees Celsius, and finally spun into anion fibers.

[0058] 3) The particle filter layer 2 selects PP melt-blown filter paper with a filter efficiency of 95%.

[0059] 4) Adsorption catalytic particle layer 3 is activated carbon supported metal oxide MnO x Mix the Mn precursor manganese nitrate solution with activated carbon, impregnate and stir, impregnate for 24 hours, and then bake at 300°C for 30 minutes to obtain room temperature catalytic oxidation of formaldehyde catalyst particles, thus making adsorption catalytic particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com