Preparation method of carbonaceous adsorbent modified by nanometer cuprous oxide/copper and application in iodine removal

A technology of nano-cuprous oxide and carbon-based adsorbents, which is applied in chemical instruments and methods, radioactive purification, and other chemical processes. It can solve the problems of low adsorption performance and achieve low cost, mild preparation conditions, and simple processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

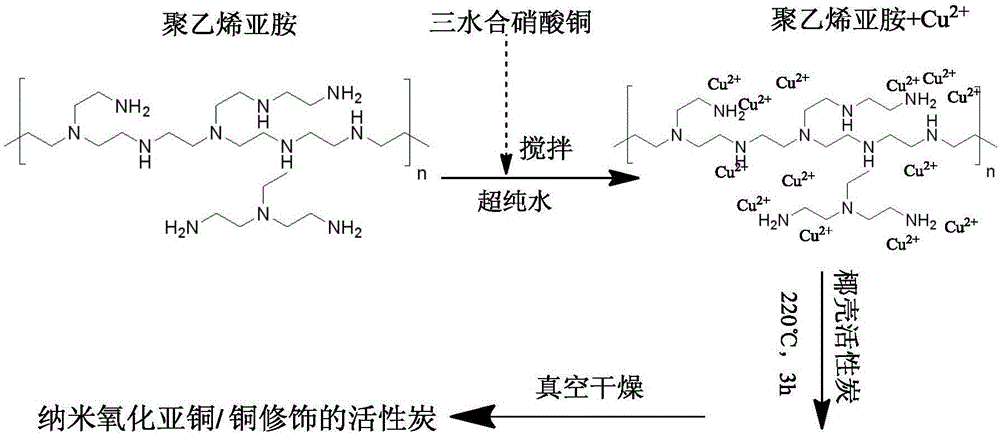

[0024] First weigh 1.32g of polyethyleneimine, add 100mL of ultrapure water, and stir magnetically until it is completely dissolved. Then add 1.97g of copper nitrate and stir magnetically to obtain a uniform blue solution. Take by weighing 2g coconut shell activated carbon again, magnetic stirring. Put it into an autoclave, seal the reactor, and keep it at 220° C. for a constant temperature hydrothermal reaction for 3 hours. After the autoclave was naturally cooled to room temperature, the obtained sample was washed with deionized water several times, and vacuum-dried at 60°C to obtain nano-cuprous oxide / copper-modified activated carbon, such as figure 1 shown.

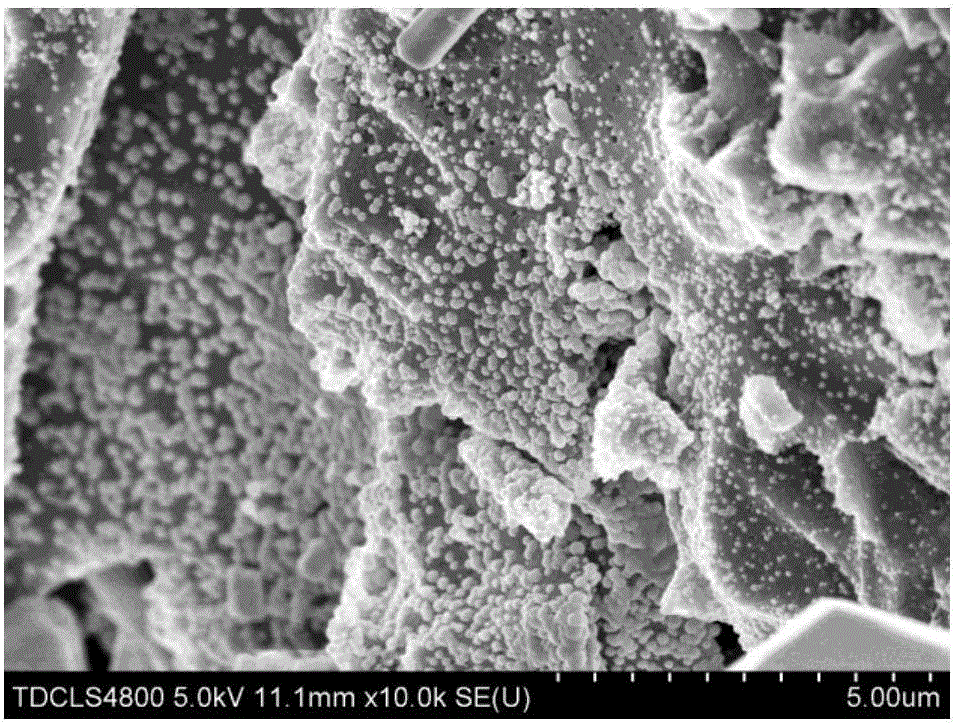

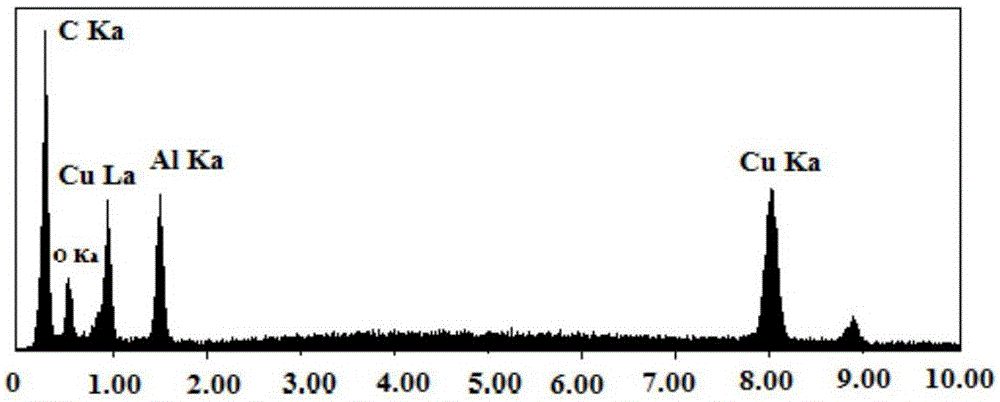

[0025] The morphology of the prepared nano-cuprous oxide / copper-modified activated carbon was observed by scanning electron microscopy (SEM), and the chemical element composition of the nano-cuprous oxide / copper-modified activated carbon was analyzed by energy dispersive spectroscopy (EDS), which was used to adsorb ...

Embodiment 2

[0027] First weigh 1.06g of polyethyleneimine, add 100mL of ultrapure water, and stir magnetically until it is completely dissolved. Then add 1.18g of copper nitrate, stir magnetically to obtain a uniform blue solution. Take by weighing 2g coconut shell activated carbon again, magnetic stirring. Put it into an autoclave, seal the reactor, and keep it at 180° C. for a constant temperature hydrothermal reaction for 3 hours. After the autoclave was naturally cooled to room temperature, the obtained sample was washed with deionized water several times, and vacuum-dried at 50° C. to obtain nano-cuprous oxide / copper-modified activated carbon.

[0028] Add 1g / L nano-cuprous oxide / copper-modified activated carbon to the water containing 2mg / L simulated radioactive iodide ions, the temperature is 25°C, and the stirring speed is 200 rpm. Compared with Example 1, the adsorption efficiency of nano cuprous oxide / copper modified activated carbon prepared in Example 2 was 95.7%.

Embodiment 3

[0030] First weigh 3.05g of polyethyleneimine, add 100mL of ultrapure water, and stir magnetically until it is completely dissolved. Then add 5.90g of copper nitrate, and magnetically stir to obtain a uniform blue solution. Take by weighing 2g coconut shell activated carbon again, magnetic stirring. Put it into an autoclave, seal the reactor, and keep it at 200° C. for a constant temperature hydrothermal reaction for 3 hours. After the autoclave was naturally cooled to room temperature, the obtained samples were washed with deionized water several times, and dried in vacuum at 80° C. to obtain nano-cuprous oxide / copper-modified activated carbon.

[0031] Add 1g / L nano-cuprous oxide / copper-modified activated carbon to the water containing 2mg / L simulated radioactive iodide ions, the temperature is 25°C, and the stirring speed is 200 rpm. Compared with Example 1, the adsorption efficiency of nano cuprous oxide / copper modified activated carbon prepared in Example 3 was 84.1%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com