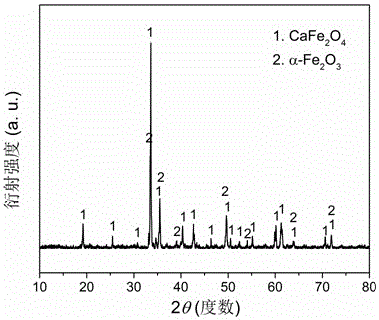

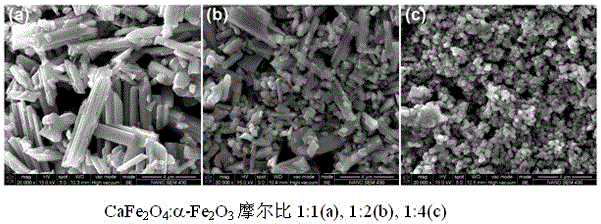

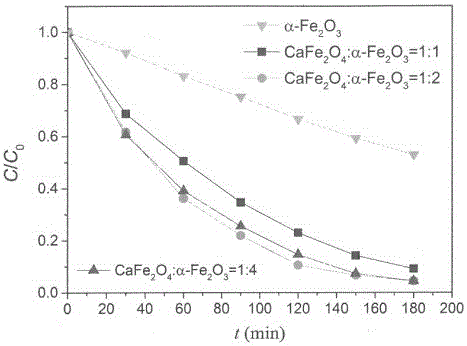

pn type CaFe2O4@alpha-Fe2O3 heterojunction compound photocatalyst and preparation method and application thereof

A heterojunction and composite light technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve low production costs, cost saving, and good recyclability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 0.4mol / L FeCl 3 and 0.1mol / L CaCl 2 Mix 10 mL each of the solutions and add 0.69 g of Na 2 C 2 o 4 , mixed and stirred for 30min to obtain a clear mixed solution.

[0031] (2) Under stirring, use 1mol / L NaOH solution to adjust the pH value of the mixed solution prepared in step (1) to 5, dilute the solution to 50mL with deionized water, and transfer it into PTFE stainless steel high-pressure water In a thermal reaction kettle, conduct a hydrothermal reaction at 160°C for 8 hours, and cool naturally to room temperature to obtain a solid-liquid system containing primary precipitates.

[0032] (3) Use 1mol / L NaOH solution to adjust the pH of the solid-liquid system obtained in step (2) to 8.5, stir for 30 minutes and then let it stand for 8 hours, then wash with deionized water and ethanol three times each, and remove the precipitate Dry at 80°C for 12 hours and grind to obtain a precursor.

[0033] (4) Heat-treat the precursor prepared in step (3) in an air...

Embodiment 2

[0037] (1) Take 0.6mol / L FeCl 3 and 0.1mol / L CaCl 2 10 mL of the solution was mixed and 0.97 g of Na 2 C 2 o 4 , mixed and stirred for 40min to obtain a clear mixed solution.

[0038] (2) While stirring, use 0.8mol / L KOH solution to adjust the pH value of the mixed solution prepared in step (1) to 4.5, use deionized water to make the solution volume up to 70mL, and transfer it into a polytetrafluoroethylene stainless steel high-pressure In a hydrothermal reaction kettle, conduct a hydrothermal reaction at 180°C for 6 hours, and cool naturally to room temperature to obtain a solid-liquid system containing primary precipitates.

[0039] (3) Use 0.8 mol / L KOH solution to adjust the pH of the solid-liquid system obtained in step (2) to 9, stir for 40 minutes and let it stand for 7 hours, wash with deionized water and ethanol three times each, and remove the precipitate The material was dried at 70°C for 20 hours and ground to obtain the precursor.

[0040] (4) Heat-treat the...

Embodiment 3

[0044] (1) Take 1mol / L FeCl 3 and 0.1mol / L CaCl 2 10 mL each of the solution was mixed, and 1.5 g of Na 2 C 2 o 4 , mixed and stirred for 50 min to obtain a clear mixed solution.

[0045] (2) Under stirring, use 0.5mol / L ammonia water to adjust the pH value of the mixed solution prepared in step (1) to 5.5, use deionized water to dilute the solution to 100mL, and transfer it into PTFE stainless steel high-pressure water In a hot reaction kettle, hydrothermally react at 170°C for 7 hours, and cool down to room temperature naturally to obtain a solid-liquid system containing primary precipitates.

[0046] (3) Use 0.5 mol / L ammonia water to adjust the pH of the solid-liquid system obtained in step (2) to 9.5, stir for 50 minutes and let it stand for 6 hours, wash with deionized water and ethanol three times each, and remove the precipitate Dry at 90°C for 10 hours and grind to obtain the precursor.

[0047] (4) Heat-treat the precursor prepared in step (3) in an air atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com