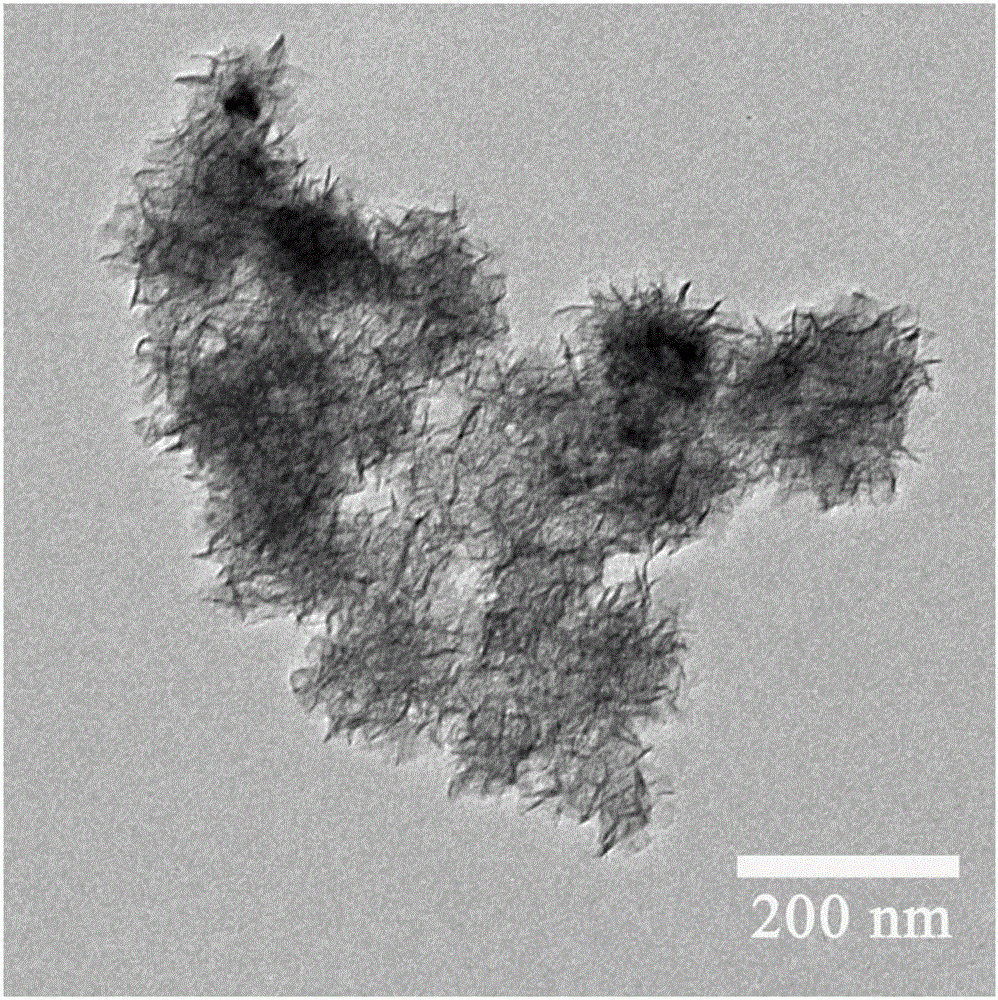

Flower-like mesoporous titanium dioxide hierarchical structure and preparation method thereof

A technology of mesoporous titanium dioxide and hierarchical structure, applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems such as thick is not conducive to lithium storage, excessive thickness of nanoparticles, and achieves easy implementation of process operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In order to overcome the deficiencies in the prior art, the present invention provides a method for preparing a novel flower-like mesoporous titanium dioxide hierarchical structure, comprising the following steps:

[0048] (1) Cetyl trimethyl ammonium bromide (CTAB) is fully dissolved in water, then add didodecyl dimethyl ammonium bromide (DDAB), continue stirring to form a transparent solution, then add a small amount of ammonia water and stir well;

[0049] Wherein, the stirring temperature is 25-40° C., and the stirring speed is 300-450 r / min.

[0050] The molar ratio of CTAB and DDAB is 1:(0.978-1.126).

[0051] The addition ratio of the CTAB, ammonia water and water is 1 g: (4-6) mL: (240-260) mL.

[0052] The mass concentration of ammonia water is 23%-25%.

[0053] (2) Tetraethyl orthosilicate (TEOS) and titanium oxysulfate (TiOSO 4 ) is dispersed in absolute ethanol solution;

[0054] Among them, TEOS and TiOSO 4 The molar ratio is 1:(0.35~0.65).

[0055] ...

Embodiment 1

[0068] Add 0.141g CTAB into a 100mL beaker and place it on a magnetic stirrer, add 35mL deionized water and raise the temperature to 35°C, adjust the rotation speed to 350r / min to dissolve completely, then add 1.174g DDAB to form a transparent solution, then add 0.7 mL ammonia, then stirred for 2h; 2g TEOS and 0.768g TiOSO 4 Disperse in 15mL ethanol solution and slowly add the mixture dropwise to the above solution with stirring, and stir for 24h. The obtained white suspension was transferred to a 100mL reaction kettle, and placed in a thermostat at 100°C for 24h. After cooling, the white precipitate was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 55° C. for 10 h, and then the precipitate was calcined in a tubular calciner at 500° C. for 4 h to obtain a silica / titania composite material. Add 80mg of silica / titanium dioxide composite material into 40mL of 0.5M NaOH solution and react for...

Embodiment 2

[0070] Add 0.141g CTAB into a 100mL beaker and place it on a magnetic stirrer, add 35mL deionized water and raise the temperature to 35°C, adjust the rotation speed to 350r / min to dissolve completely, then add 1.174g DDAB to form a transparent solution, then add 0.7 mL ammonia, then stirred for 2h; 2g TEOS and 0.768g TiOSO 4 Disperse in 15mL ethanol solution and slowly add the mixture dropwise to the above solution with stirring, and stir for 24h. The obtained white suspension was transferred to a 100mL reaction kettle, and placed in a thermostat at 130°C for 24h. After cooling, the white precipitate was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 55° C. for 10 h, and then the precipitate was calcined in a tubular calciner at 500° C. for 4 h to obtain a silica / titania composite material. Add 80 mg of silica / titania composite material into 40 mL of NaOH solution with a concentration of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com