Synthesis technology of tetrasodium iminodisuccinate

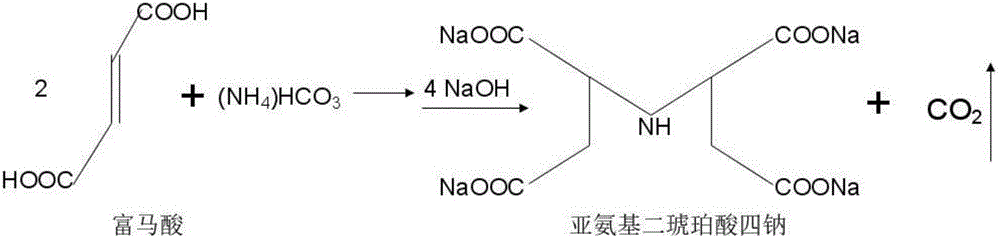

A technology of tetrasodium iminodisuccinate and synthesis process, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry and other directions, can solve problems such as environmental pollution, achieve simple equipment, safe and convenient operation, and rich product types Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The fumaric acid that adopts in this implementation is food grade, and ammonium bicarbonate, water, alkali are industrial grade.

[0034] The fertilizer synergistic chelating agent-tetrasodium iminodisuccinate was prepared by the following process.

[0035] (1) In the 5 square enamel kettle, add 1587kg water successively, 1032kg fumaric acid, 352kg ammonium bicarbonate, stir;

[0036] (2) heat preservation at 50° C., and stir at 22 rpm for 10 h to obtain an iminodisuccinic acid solution;

[0037] (3) Add 32% (mass concentration) of liquid caustic soda 2225kg in the iminodisuccinic acid solution, obtain the tetrasodium iminodisuccinate solution of 5000kg30% (mass concentration). The finally obtained solid tetrasodium iminodisuccinate with a purity of 98% after removing water contains 1% unreacted fumaric acid and 1% malic acid.

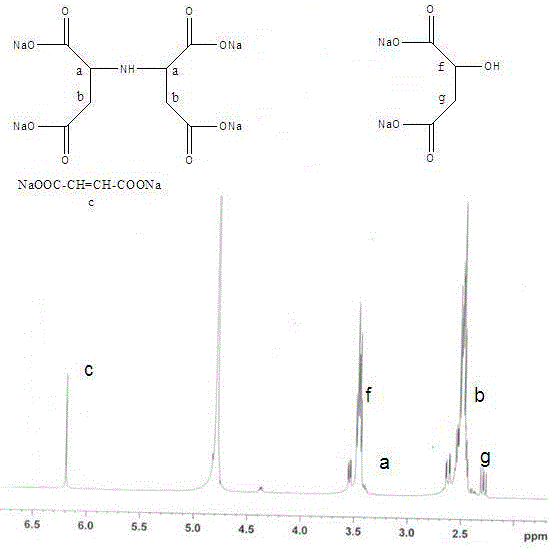

[0038] The product that this embodiment obtains is carried out 1 H-NMR (D 2 O), the results please see the accompanying drawings figure 1 ...

Embodiment 2

[0040] (1) In the 5 square enamel kettle, add 1587kg water successively, 1032kg fumaric acid, 352kg ammonium bicarbonate;

[0041] (2) Stirring at a rate of 40 rpm for 7 hours at 60° C. under heat preservation to obtain an iminodisuccinic acid solution.

[0042] (3) Add 32% (mass concentration) of liquid caustic soda 2225kg in the iminodisuccinic acid solution, obtain the tetrasodium iminodisuccinate solution of 5000kg30% (mass concentration). The finally obtained solid tetrasodium iminodisuccinate after removing water has a purity of 95%, contains 1% unreacted fumaric acid and 4% malic acid.

[0043] The difference between this embodiment and Example 1 is: 1) In step a, the reaction temperature is increased by 60°C, the corresponding reaction rate is accelerated, and the reaction time is shortened to 6h; when the reaction temperature is increased, although the reaction rate is increased, the corresponding The side reaction also increases, and correspondingly in step b, produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com