A method for preparing high-purity fructo-oligosaccharides using molecular sieve-simulated moving bed

A technology for simulating moving bed and fructooligosaccharides, applied in the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc., to achieve the effects of preventing hydrolysis, strong adsorption capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

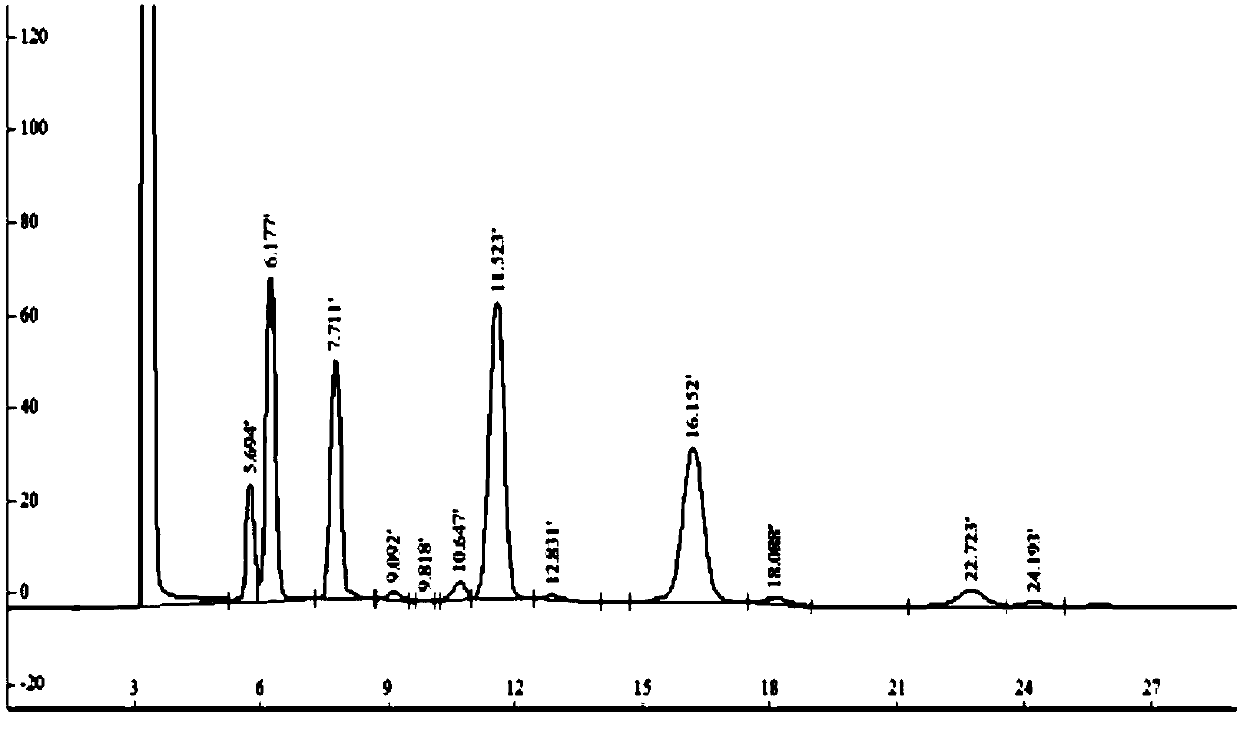

Embodiment 1

[0029] A method utilizing molecular sieve-simulated moving bed to prepare high-purity fructo-oligosaccharides, comprising the following steps:

[0030] (1) Dilution: Take the FOS60 type fructooligosaccharide mother liquor obtained after the fructosyltransferase acts on the sucrose solution, in which the total content of monosaccharide and disaccharide is 40.64%, the total content of fructooligosaccharide is 59.36%, and the hammer is 70° Ordinary grade fructooligosaccharide solution (FOS50) of Bx is used as the raw material, and the raw material is diluted with pure water to a Brix of 50°Bx to obtain dilute sugar solution;

[0031] (2) Decolorization and impurity removal: add 1.5% composite adsorbent of ordinary grade fructo-oligosaccharide liquid raw material weight to the dilute sugar solution, heat to 40°C, stir at a speed of 70r / min for 30min, filter while hot, and take the filtrate; The composite adsorbent is made up of activated carbon and polyaluminum sulfate with a weig...

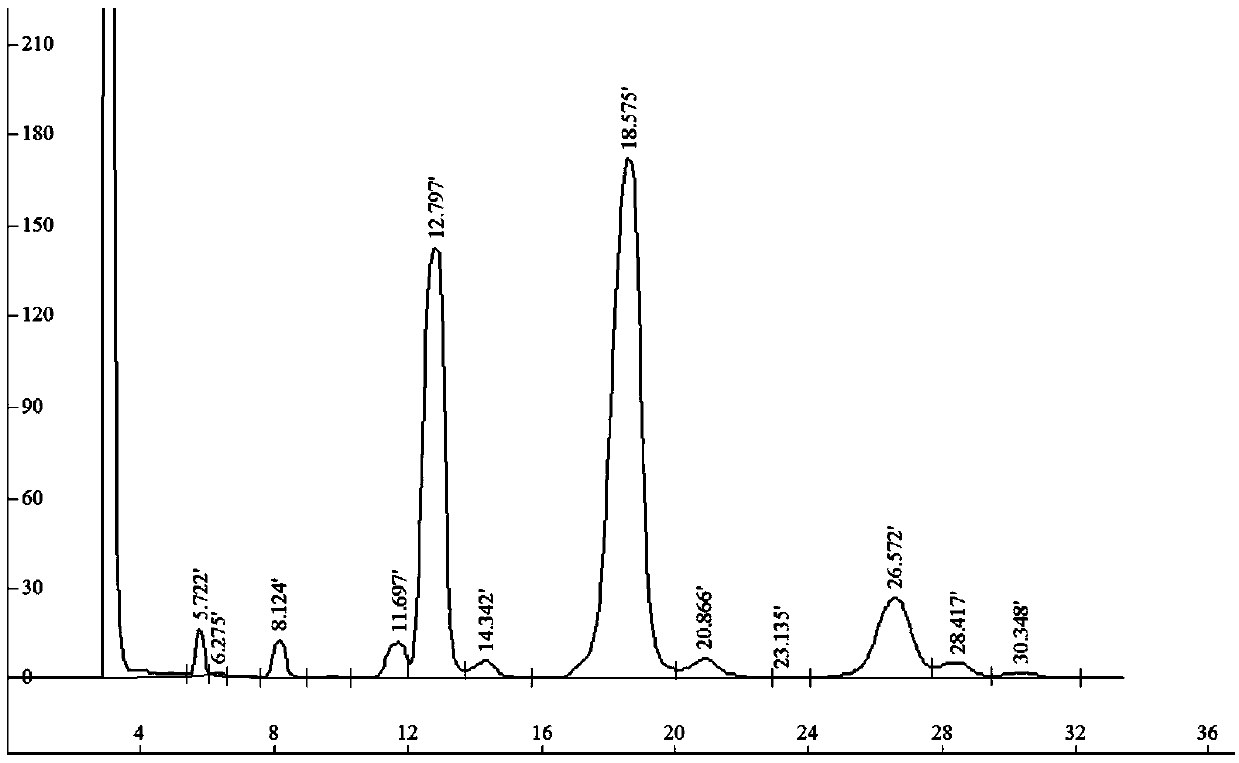

Embodiment 2

[0044] A method utilizing molecular sieve-simulated moving bed to prepare high-purity fructo-oligosaccharides, comprising the following steps:

[0045] (1) Dilution: Take the FOS55 type fructooligosaccharide mother liquor obtained after the fructosyltransferase acts on the sucrose solution, in which the total content of monosaccharide and disaccharide is 44.78%, the total content of fructooligosaccharide is 55.22%, and the hammer is 75° The ordinary grade fructo-oligosaccharide liquid of Bx is raw material, and raw material is diluted to brix with pure water and is 45 ° of Bx, obtains dilute sugar liquid;

[0046] (2) Decolorization and impurity removal: Add 2.5% composite adsorbent by weight of ordinary grade fructooligosaccharide liquid raw material to the dilute sugar solution, heat to 45°C, stir at a speed of 80r / min for 25min, filter while hot, and take the filtrate; The composite adsorbent is made up of activated carbon and polyaluminum sulfate with a weight ratio of 1:1...

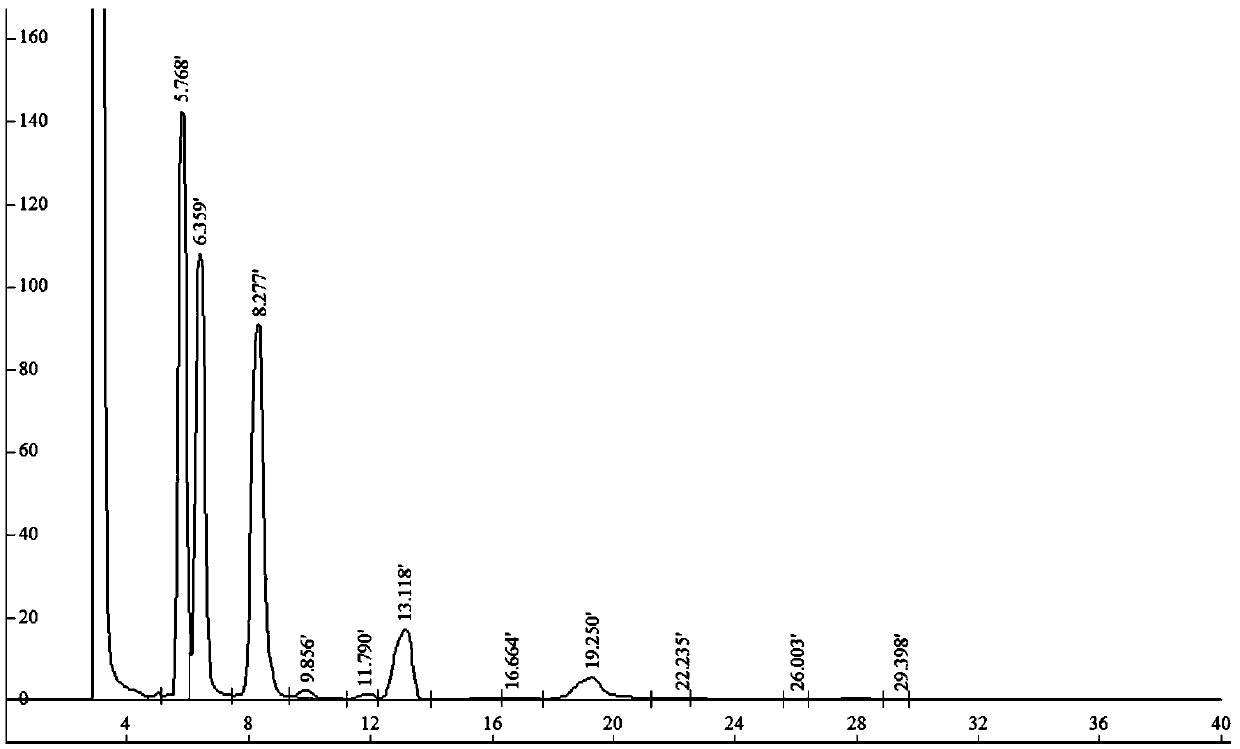

Embodiment 3

[0051] A method utilizing molecular sieve-simulated moving bed to prepare high-purity fructo-oligosaccharides, comprising the following steps:

[0052] (1) Dilution: Take the FOS60 fructooligosaccharide mother liquor obtained after the fructosyltransferase acts on the sucrose solution, in which the total content of monosaccharide and disaccharide is 41.94%, the total content of fructooligosaccharide is 59.06%, and the Brix is 78°Bx The common grade fructo-oligosaccharide liquid is raw material, and raw material is diluted to brix with pure water and is 50 ° of Bx, obtains dilute sugar liquid;

[0053] (2) Decolorization and impurity removal: Add 3.0% of the weight of ordinary grade fructooligosaccharide liquid composite adsorbent to the dilute sugar solution, heat to 45°C, stir at a speed of 75r / min for 20min, filter while it is hot, and take the filtrate; The composite adsorbent is made up of activated carbon and polyaluminum sulfate in a weight ratio of 3:1;

[0054] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com