Water-based cleaning agent and preparation method thereof

A water-based cleaning agent and preservative technology, applied in the preparation of detergent mixture composition, detergent composition, detergent compounding agent, etc., can solve a large number of foam, not in line with environmental protection and safe and harmless, cleaning workpieces Corrosion and other problems with the skin, to achieve the effect of simple operation and avoid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0028] Prepare a water-based cleaning agent, the specific components and contents are shown in Table 1, and the preparation method is as follows:

[0029] Step 1, according to the above mass percentage, take each component for subsequent use;

[0030] Step 2, mixing ethylene glycol ethers, propylene glycol ethers, alcohol amines and surfactants, fully stirring at room temperature, stirring evenly, and standing still to obtain solution A;

[0031] Step 3, adding the corrosion inhibitor and stabilizer into the reaction vessel, and stirring with a dispersing mixer for 25 to 40 minutes to fully react and dissolve to obtain solution B;

[0032] Step 4: Mix solution A and solution B, stir evenly, add deionized water, then add defoamer, make them fully mixed and dissolved, and let stand for 15-30 minutes to obtain a water-based cleaning agent.

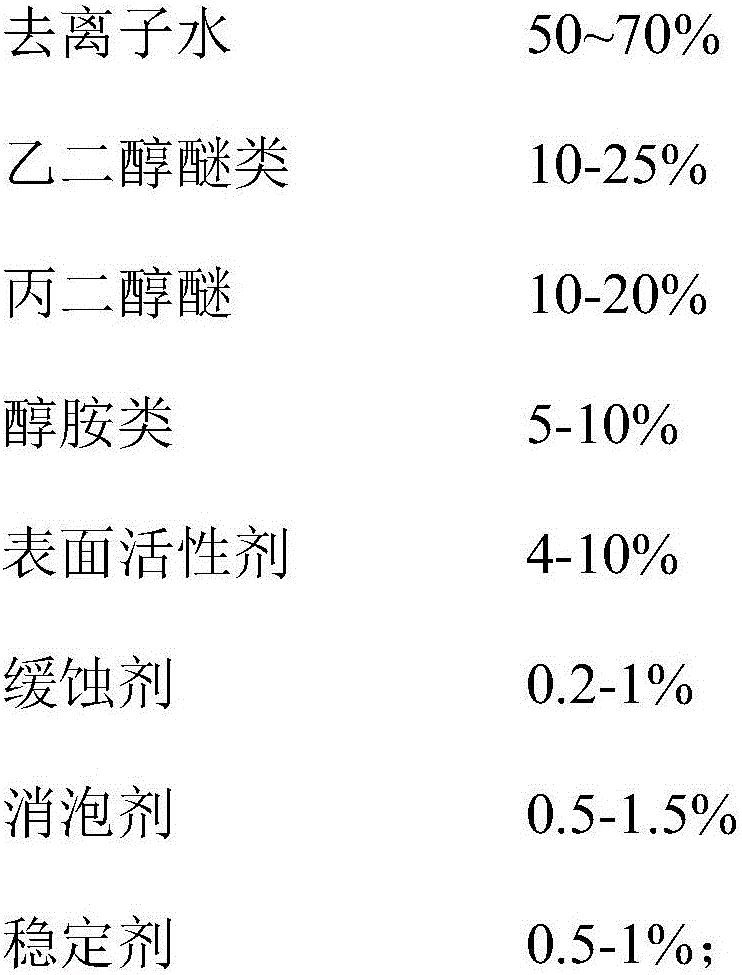

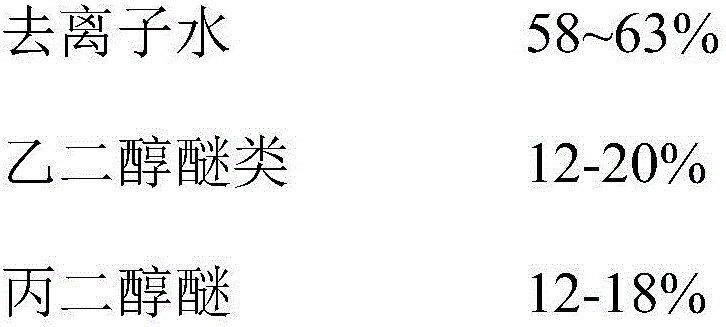

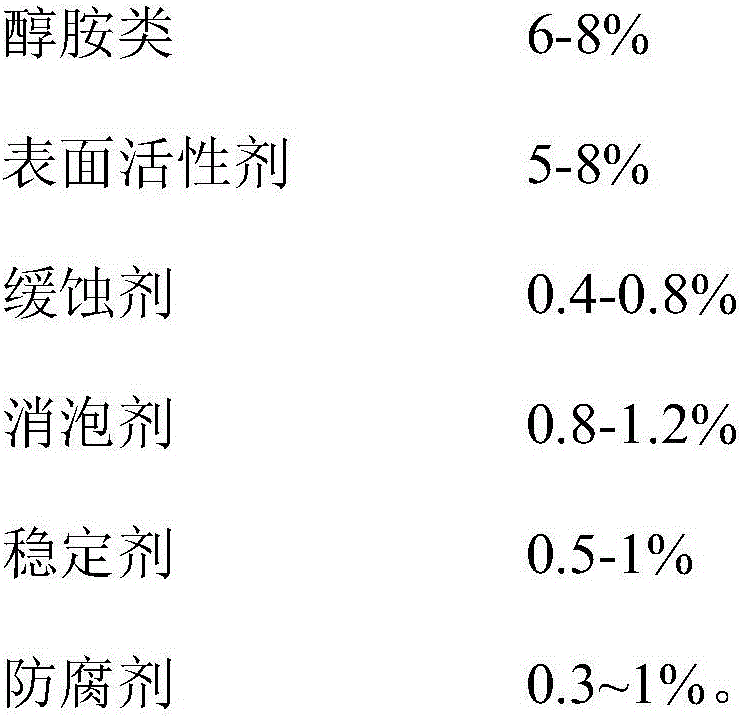

[0033] Table 1 embodiment component and content table

[0034]

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com