A kind of air compressor oil composition produced by utilizing recycled oil

A technology of air compressor oil and composition, which is applied in lubricating composition, petroleum industry, etc., can solve environmental pollution and other problems, and achieve the effects of rational utilization of resources, high viscosity index, and high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

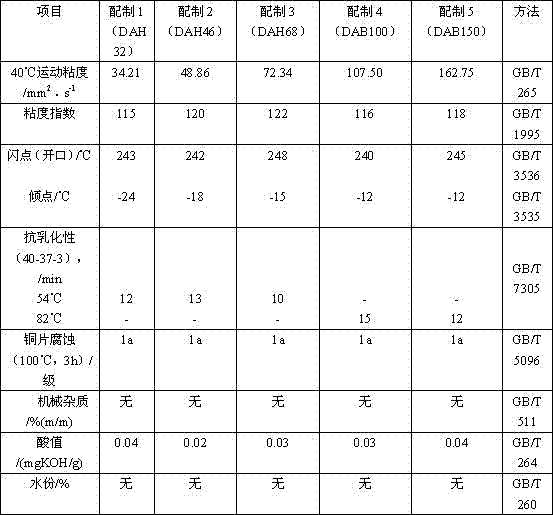

Examples

Embodiment 1

[0012] Formulated in parts by weight, air compressor oil:

[0013] Recipe 1:

[0014] 100.0 parts of regenerated base oil, 22.0 parts of 15# refined, 10.0 parts of PAO2, 2.0 parts of ethylene-propylene copolymer, 3.0 parts of low base number synthetic calcium sulfonate, 1.5 parts of polyenyl succinimide, thiophosphorus bis-octyl base 2.0 parts of zinc salt, 1.0 part of benzotriazole derivatives, 2.0 parts of sulfided isobutylene, 1.0 part of zinc naphthenate of sodium petroleum sulfonate, 0.0004 part of amine and epoxide condensate, and 0.0005 part of methyl silicone oil.

[0015] Recipe 2:

[0016] 100.0 parts of regenerated base oil, 10.5 parts of 2# sulfonated, 10.0 parts of trimethylolpropane oleate, 3.0 parts of polymethacrylate, 3.0 parts of low base number synthetic calcium sulfonate, bisalkenyl succinimide 1.0 part, 1.0 part of sulfur phosphorus primary and secondary alcohol base zinc salt, 1.5 part of 2,6-di-tert-butyl-p-cresol, 1.5 part of di-n-butyl phosphite, 1.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com