Method for preparing fruit vinegar from waste residues of column chromatography in momordica glycoside production

A technology of mogroside and column flow, which is applied in the field of preparing fruit vinegar from waste column liquid in the production of mogroside, can solve problems such as not existing, and achieve the effects of improving quality, improving immunity, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

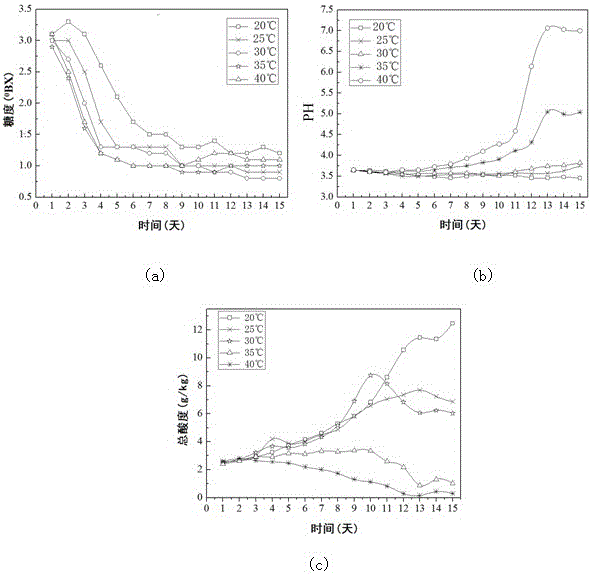

[0040] Embodiment 1: Effect of different fermentation temperatures on fermented products

[0041] Different fermentation temperatures are set, and the changes of fermentation broth at different fermentation temperatures are as follows: figure 1 shown. Depend on figure 1 (a) It can be seen that different fermentation temperatures have certain effects on the sugar content of fermented products. When the fermentation time was 0-6 days, the sugar content decreased rapidly. When the fermentation temperature was 30℃-40℃, the sugar content decreased rapidly. After the 6th day, the sugar content did not change much. Depend on figure 1 (b) It can be seen that with the change of fermentation time, the pH of the fermentation broth changes greatly. During 0-10 days of fermentation, the pH of the fermentation broth at 20°C to 30°C basically did not change, and after 10 days, the pH of the fermentation broth at 20°C to 30°C increased slowly in turn. However, the fermented liquid at 35°...

Embodiment 2

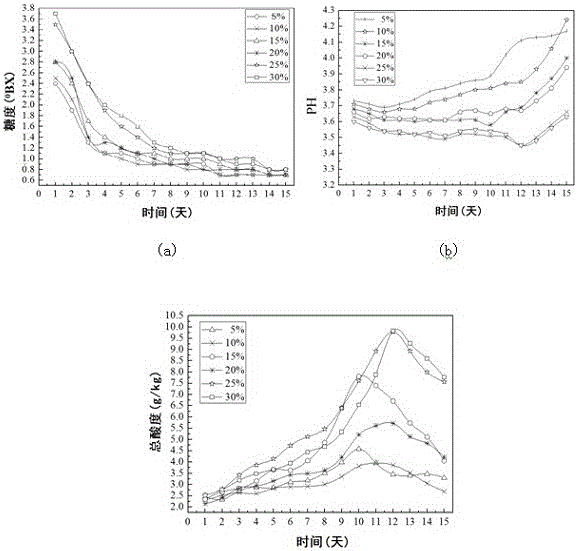

[0042] Embodiment 2: the effect of the inoculum amount of different kombucha bacteria liquids on fermented products

[0043] Inoculation of different amounts of kombucha bacteria liquid, the change of fermentation liquid is as follows: figure 2 shown. Depend on figure 2 (a) It can be seen that the sugar content of the fermentation broth with large inoculation amount is higher, and the sugar content of the fermentation broth with 15% and 20% kombucha inoculation amount drops rapidly in the early stage, and the sugar content is moderate after stabilization. Depend on figure 2 (b) It can be seen that when the inoculum size is different, the fermentation broth changes greatly with the fermentation time. The PH of the fermented liquid with inoculum amount of 5% and 10% rises faster, the pH value of the fermented liquid with inoculum amount of 25% and 30% has no obvious change in the early stage, the acidity is low, and the activity of the bacteria is not high, while the inocu...

Embodiment 3

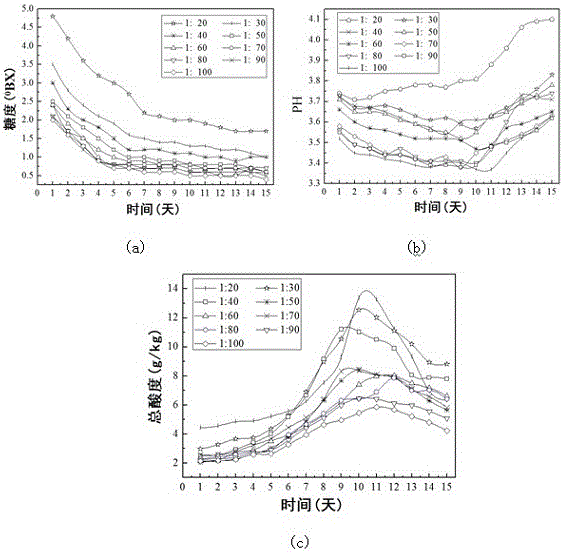

[0044] Example 3: The effect of the dilution ratio of concentrated Luo Han juice without sweet glycosides on fermented products

[0045] When the sweet glycoside-free concentrated Luo Han juice is diluted into different ratios, the changes of the fermentation broth are as follows: image 3 shown. Depend on image 3 (a) It can be seen that the lower the dilution ratio of sweet glycoside-free concentrated Luo Han juice, the higher the sugar content of the fermentation broth. When the dilution ratio of glucoside-free concentrated Luo Han juice was 1:30-1:50, the sugar content of the fermentation broth changed slowly in the early stage, and the sugar content was higher when it was flat in the later stage. Depend on image 3 (b) It can be seen that the pH value of the fermentation broth is different at different dilution ratios, and the overall trend shows a trend of first decreasing and then increasing. When the dilution ratio of glucoside-free concentrated Luo Han juice is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com