A kind of w-ni-fe-y-zrb2 multiphase alloy material and preparation method thereof

A w-ni-fe-y-zrb2, multi-phase alloy technology, applied in the field of W-Ni-Fe-Y-ZrB2 multi-phase alloy materials and its preparation, can solve the problems of room temperature plasticity, high temperature strength and oxidation resistance Achieve good matching and other issues, achieve excellent high temperature oxidation resistance, improve high temperature strength, improve room temperature plasticity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of W-Ni-Fe-Y-ZrB 2 The preparation method of multi-phase alloy material, its preparation steps are: (1) weigh Ni, Fe, Y, ZrB by mass percentage 2 and W each raw material, and then the raw materials weighed are mixed uniformly by ball milling under the protection of argon to obtain a mixed powder;

[0024] (2) Prepare the shell, put the mixed powder described in step (1) into the shell, and seal the shell after vacuuming;

[0025] (3) Put the shell sealed with the mixed powder in step (2) into a hot isostatic pressing furnace, and sinter it for 1h-2h at a temperature of 1400°C-1600°C and a pressure of 100MPa-200MPa , the shell was removed after natural cooling to obtain W-Ni-Fe-Y-ZrB 2 multiphase alloy materials.

[0026] It is worth noting that the ball mill is a dry ball mill, the equipment of the ball mill is a planetary ball mill, the ball mill jar in the planetary ball mill is a tungsten alloy ball mill jar, the grinding balls are tungsten alloy balls, and...

Embodiment 1

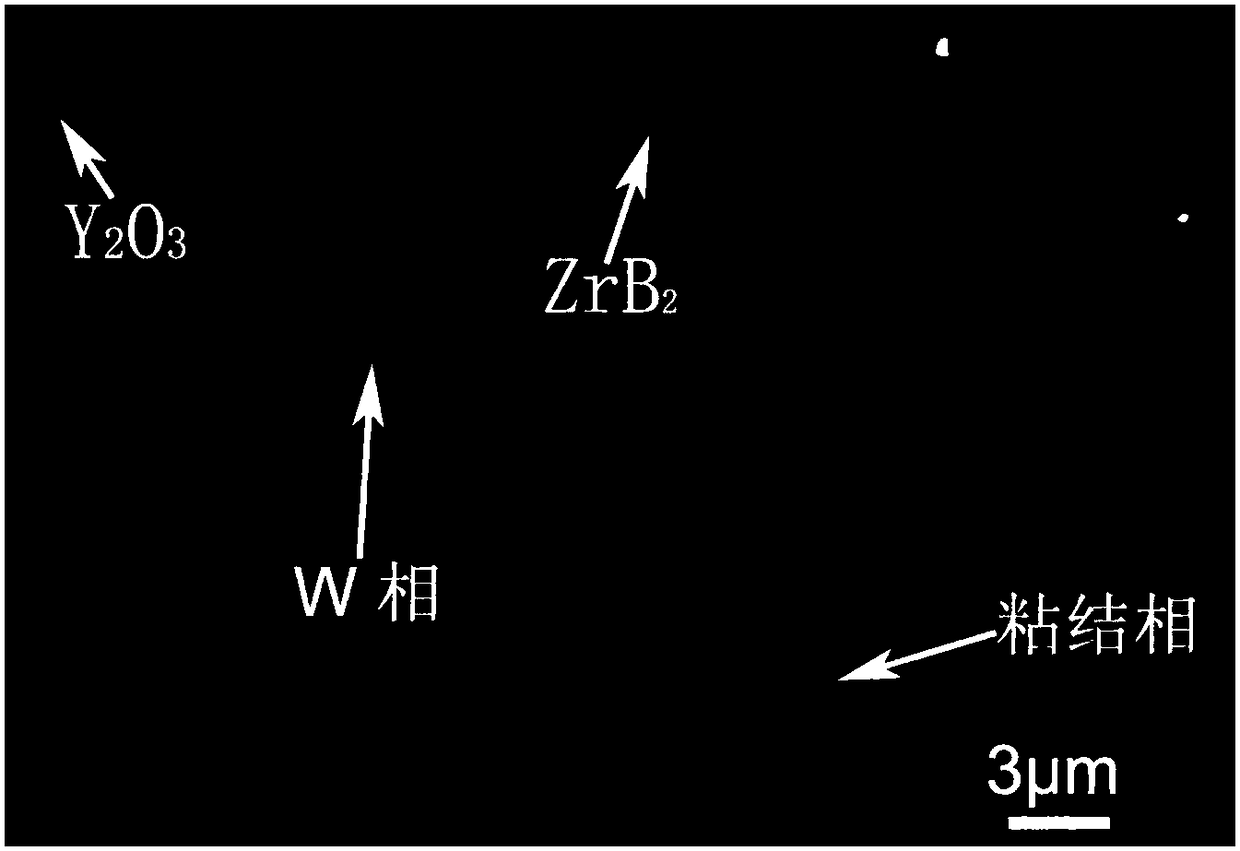

[0029] Embodiment 1: A kind of W-Ni-Fe-Y-ZrB 2 Multi-phase alloy material, made of raw materials with the following mass percentages: Ni5%, Fe 2.5%, Y 8%, ZrB 2 3%, W 81.5%; all raw materials are powder raw materials, in which the particle size of Ni powder is not greater than 3μm, the particle size of Fe powder is not greater than 6μm, ZrB 2 The particle size of the W powder is not greater than 5 μm, and the particle size of the W powder is not greater than 10 μm; the Ni powder, Fe powder, Y powder and ZrB powder 2 The mass purity of the powders is not less than 99%, and the mass purity of the W powder is not less than 99.9%.

[0030] The W-Ni-Fe-Y-ZrB2 The preparation method of multi-phase alloy material comprises the following steps:

[0031] (1) Weigh W, Ni, Fe, Y, ZrB by mass percentage 2 Each raw material is then mixed evenly by ball milling the weighed raw materials to obtain a mixed powder; the ball mill is a dry ball mill, the equipment of the ball mill is a plane...

Embodiment 2

[0037] Embodiment 2: A kind of W-Ni-Fe-Y-ZrB 2 Multi-phase alloy material, made of raw materials with the following mass percentages: Ni2%, Fe 1%, Y 5%, ZrB 2 1%, W 91%; all raw materials are powder raw materials, in which the particle size of Ni powder is not greater than 3μm, the particle size of Fe powder is not greater than 6μm, ZrB 2 The particle size of the powder is not greater than 5 μm, and the particle size of the W powder is not greater than 10 μm; the Ni powder, Fe powder, Y powder and ZrB powder 2 The mass purity of the powders is not less than 99%, and the mass purity of the W powder is not less than 99.9%.

[0038] The W-Ni-Fe-Y-ZrB 2 The preparation method of multi-phase alloy material comprises the following steps:

[0039] (1) Weigh W, Ni, Fe, Y, ZrB by mass percentage 2 Each raw material is then mixed evenly by ball milling the weighed raw materials to obtain a mixed powder; the ball mill is a dry ball mill, the equipment of the ball mill is a planetary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com