Method for modifying surface of metal cerium

A metal cerium modification technology, applied in the field of metal cerium surface modification, metal cerium surface nitriding and coating treatment to improve its anti-aging and corrosion performance, can solve the problem of easy oxidation and corrosion, affecting metal characteristics and surface appearance quality, aging and other problems, to achieve the effect of enhancing the anti-aging and corrosion performance and increasing the aesthetic effect of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

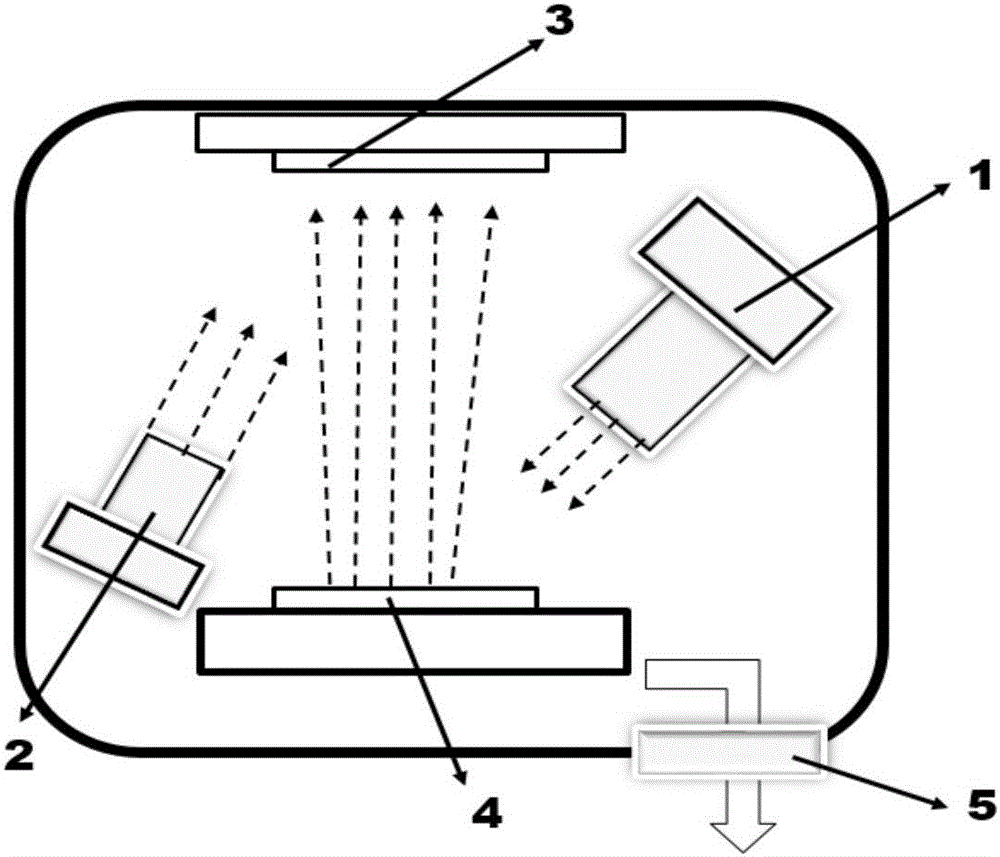

[0029] 1) The metal cerium sample (10mm×10mm×3mm) that has been polished, polished and ultrasonically cleaned is immediately placed on the substrate stage in the vacuum chamber of the dual ion beam sputtering deposition system, and the chamber is closed for vacuuming;

[0030] 2) The background vacuum reaches 8.5×10 -5 After Pa, the auxiliary source is fed with argon gas, the flow rate is 5 sccm, and the working gas pressure is 0.9×10 -2 Pa, the working parameters are auxiliary source ion energy 600eV (electron volts), beam current 35mA, the metal cerium sample is sputtered and cleaned for 15 minutes, and then the auxiliary source is stopped;

[0031] 3) The main source is connected with argon gas, the flow rate is 7sccm, and the working gas pressure is 1.5×10 -2 Pa, the working parameters are argon ion energy 2500eV, beam current 80mA, sputtering and cleaning the pre-polished and polished high-purity metal cerium target, preparing for reactive sputtering, and stopping the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com