Sealing device for pipeline inner diameter welding seam

A technology of sealing device and inner diameter, which is applied to the device of coating liquid on the surface, pipeline protection, pipeline anticorrosion/rust protection, etc., which can solve the problems of pipelines being corroded by soil, poor versatility of special equipment, and no way to protect pipelines, etc. , to achieve the effect of simple and practical overall structure, convenient operation and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

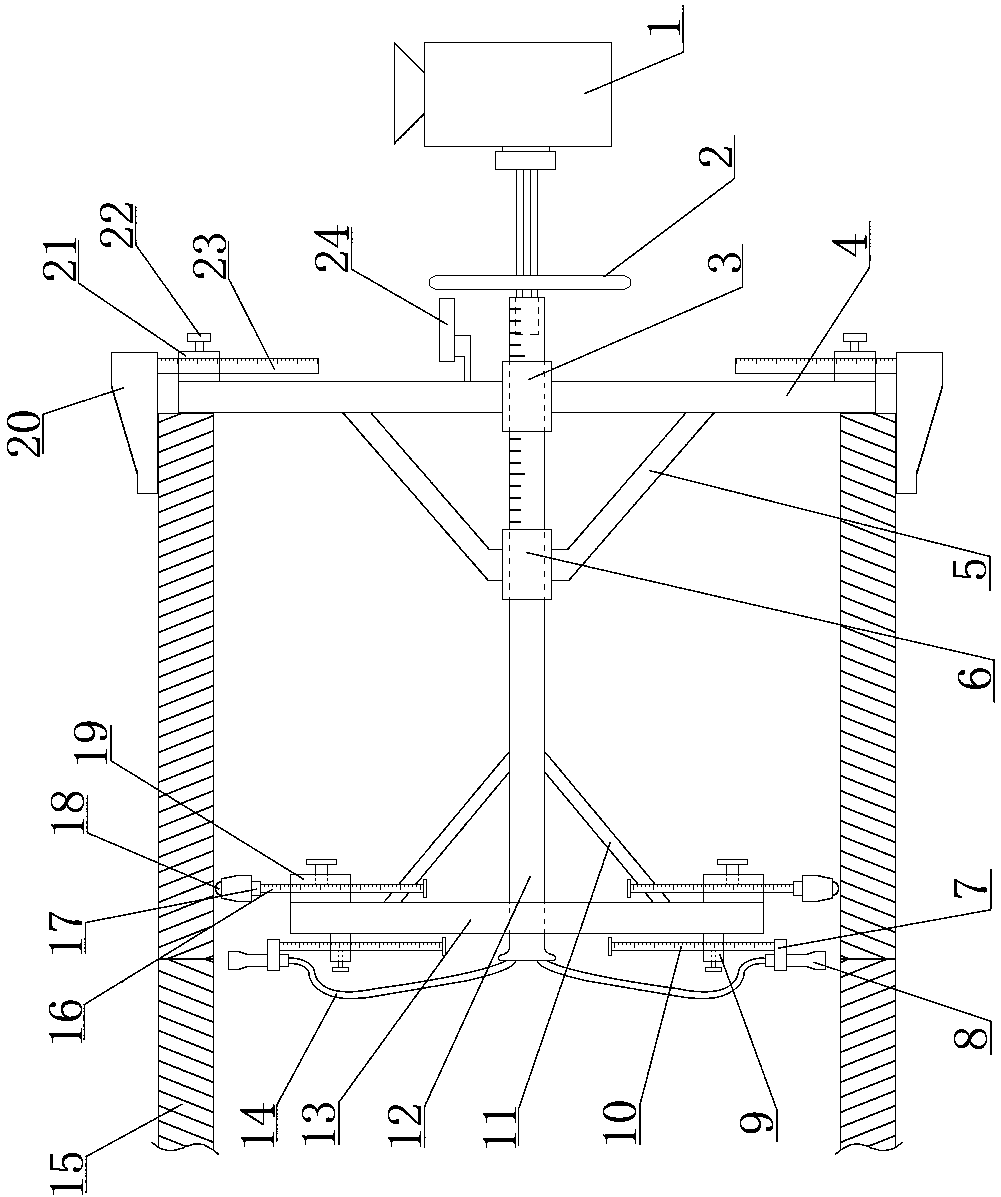

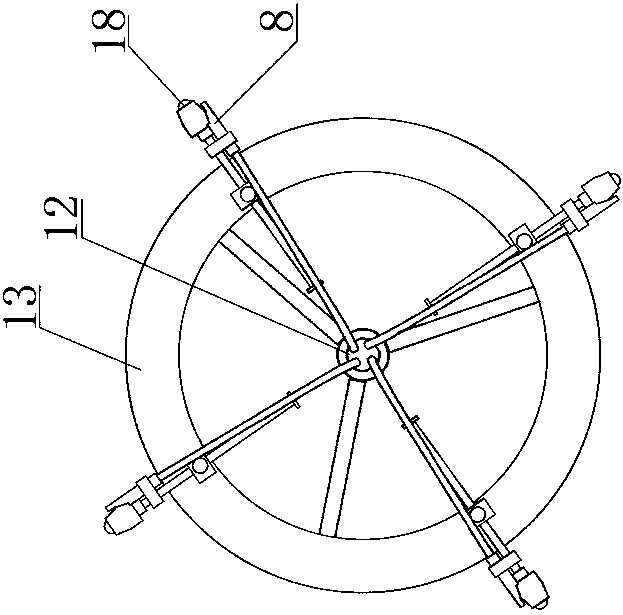

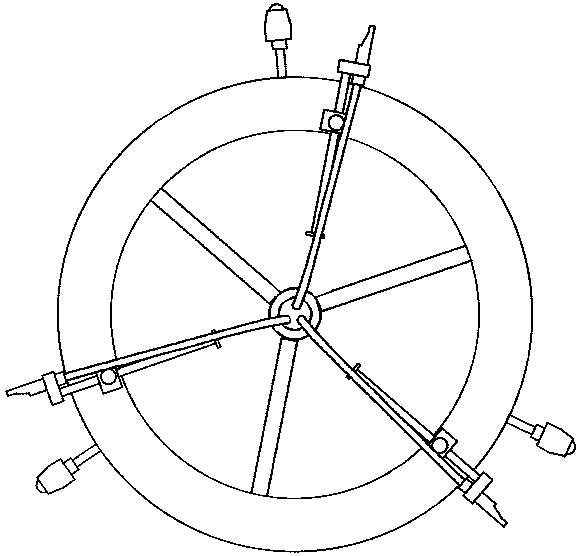

[0041] Refer to attached figure 1 to attach Figure 5 , the present invention includes a walking device and a fixing device;

[0042] The walking device includes a support disc 13, and the center of the support disc 13 is fixed with a support sleeve 12 whose front end is vertically connected to it;

[0043] The two sides of the outer diameter of the support disc 13 are respectively provided with a corresponding walking base 19 and a rubber base 9; the walking base 19 and the rubber base 9 are respectively provided with a telescopic support arm I16 with a scale and the telescopic support arm II10, and the telescopic support arm I16 and the telescopic support arm II10 are respectively fastened and limited by fastening bolts, the walking base 19 and the rubber base 9; connected to each other; the top of the telescopic support arm II10 is connected to the glue injection nozzle 8; the glue injection nozzle 8 communicates with the glue pumping station 1 through the hose 14;

[00...

Embodiment 2

[0062] The present invention also relates to the improvement of the universal rubber wheel material, specifically, the universal rubber wheel is prepared according to the following process:

[0063] 1) Add diatomaceous earth to twice the weight of 1M sodium hydroxide solution, stir evenly, then let it stand for 60 minutes, collect the precipitate, and then add silane coupling agent (vinyl silane), formaldehyde and Melamine was mixed evenly, and then sent into a supercritical carbon dioxide reactor, the temperature was adjusted to 50°C, the pressure was 3MPa, carbon dioxide was introduced, stirred for 90min, taken out, and dried at 80°C for 3h to obtain material 1; the diatomite, silane The mass ratio of coupling agent, formaldehyde and melamine is 10:1:3:2;

[0064] 2) Add graphite powder, glass fiber and serine into the stirring tank in turn, and stir while heating. When heated to 90°C, add titanate coupling agent (kh550), and continue to stir for 30 minutes under heat preser...

Embodiment 3

[0067] The performance test of the universal rubber wheel material that the embodiment of the present invention 2 prepares:

[0068] Set up a control group: Control 1: replace material 1 with diatomaceous earth, and the rest are the same as in Example 2; Control 2: do not add graphite powder, and the rest are the same as in Example 2; Control 3: do not add glass fiber, and the rest are the same as in Example 2; The above-mentioned groups of materials were made into standard test pieces according to the test standards, and the performance test was carried out. Among them, MM1000 inertial brake testing machine was used for the wear test, the brake pressure was 0.5MPa, and the brake speed was 3000prm. The specific test results are shown in Table 1:

[0069] Table 1

[0070] group

[0071] Conclusion: The universal rubber wheel of the present invention has the advantages of reasonable raw material compatibility, simple and feasible process, small friction coefficient, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com