Secondary hydraulic jacking installation method of smoke desulfurizing tower transformation of coal-fired power plant

A secondary hydraulic, installation method technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., to achieve uniform jacking force, reduced use, and guaranteed welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

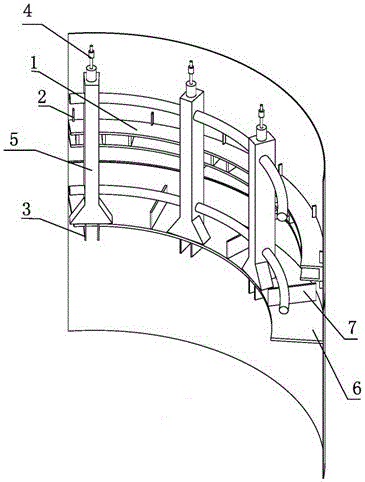

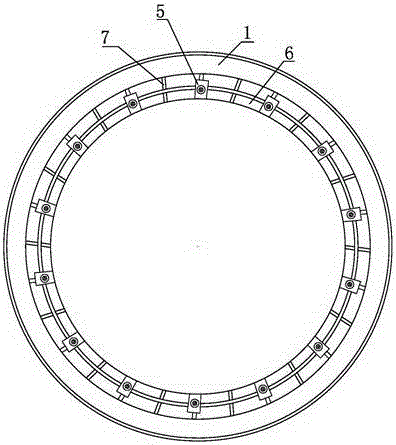

[0045] A secondary hydraulic jacking installation method for the renovation of a flue gas desulfurization tower in a coal-fired power plant. In the renovation of the desulfurization tower in this embodiment, the original tower body is cut twice, and the height of the tower body is raised by two hydraulic jackings. remodel. It includes the following construction process steps: pre-construction preparation → dismantling the external connection of the tower → dismantling the demister → strengthening the tower body → arranging the lifting device → cutting and lifting the tower body → assembling the tower wall.

[0046] Such as Figures 1 to 2 As shown, the first lifting: lift 5.6 meters from the slurry area (6.2 meters above sea level).

[0047] 1. Construction preparation

[0048] a. Draw out the vertical and horizontal centerlines of the tower body to prepare for the positioning needs of the new tower body and other equipment;

[0049] b. According to the needs of lifting, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com