High-precision optical fiber composite cable intelligent monitoring platform

An optical fiber composite cable and intelligent monitoring technology, which is applied in the direction of temperature control, non-electric variable control, and temperature control using electric methods, can solve the problems of large maintenance, loss, and complicated wiring, and achieve strong anti-electromagnetic interference ability, High temperature measurement and positioning accuracy, good safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further perfected and described below according to the accompanying drawings of the description.

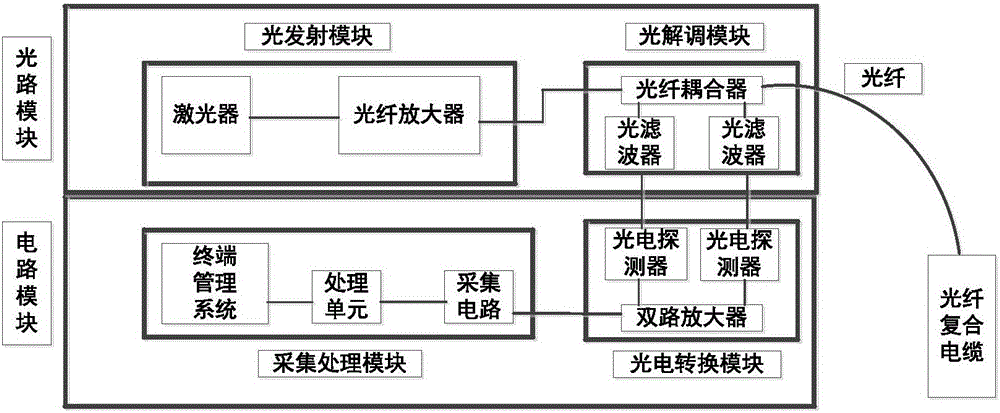

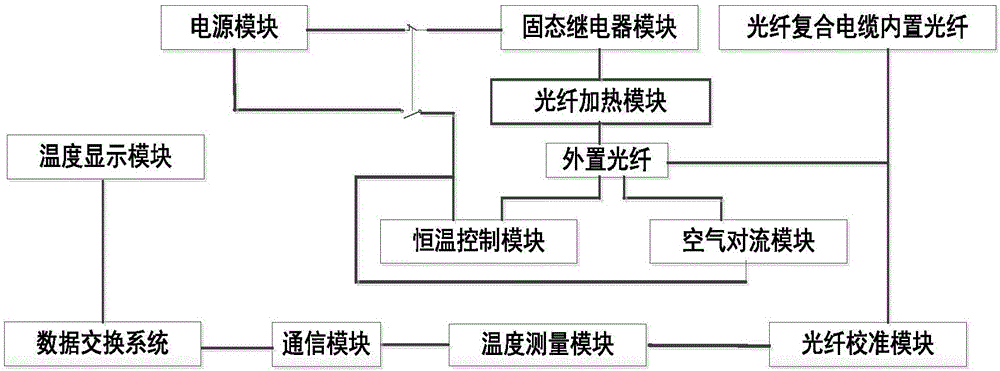

[0025] Such as figure 1 The distributed optical fiber temperature measurement system shown, this system and the optical fiber temperature measurement calibration system (such as image 3 ) temperature signal channel is connected to the temperature measurement channel 1 of the fiber optic temperature measurement host through an optical fiber jumper to realize the connection configuration between the optical fiber temperature measurement calibration system and the optical fiber temperature measurement host.

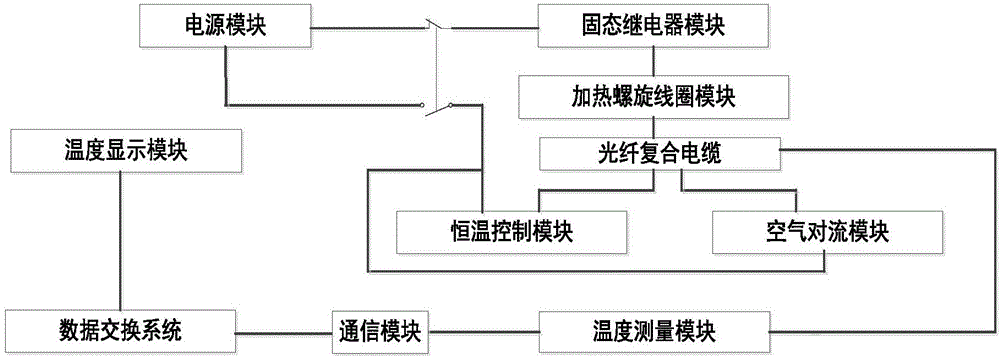

[0026] Such as figure 2 The cable heating temperature control system shown, the system and the distributed optical fiber temperature measurement system (such as figure 1) through the built-in optical fiber of the optical fiber composite cable and the temperature measurement channel 2 of the optical fiber temperature measurement host thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com