PtNi nano-alloy electrochemical sensor for detecting dopamine

A nano-alloy and dopamine technology, applied in the field of detection applications, can solve the problems of complex sensor manufacturing process and cumbersome steps, and achieve the effects of excellent linear detection range, enhanced sensitivity, and excellent anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

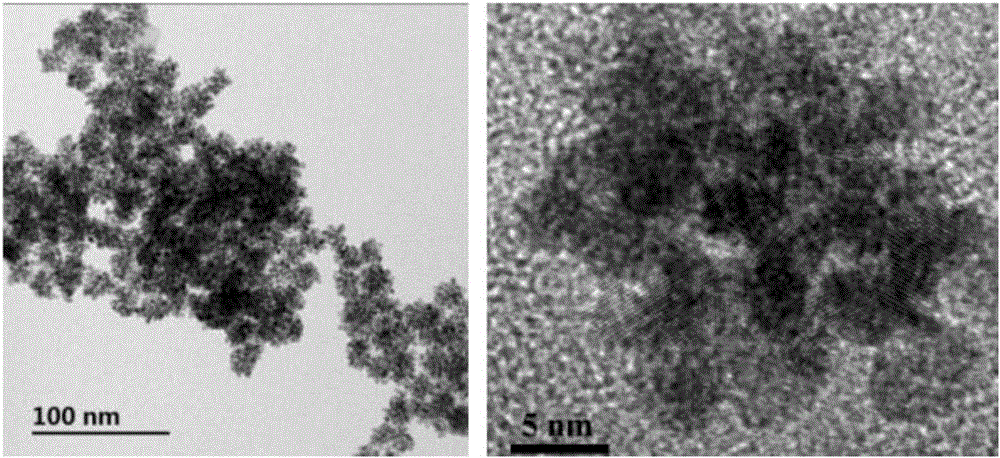

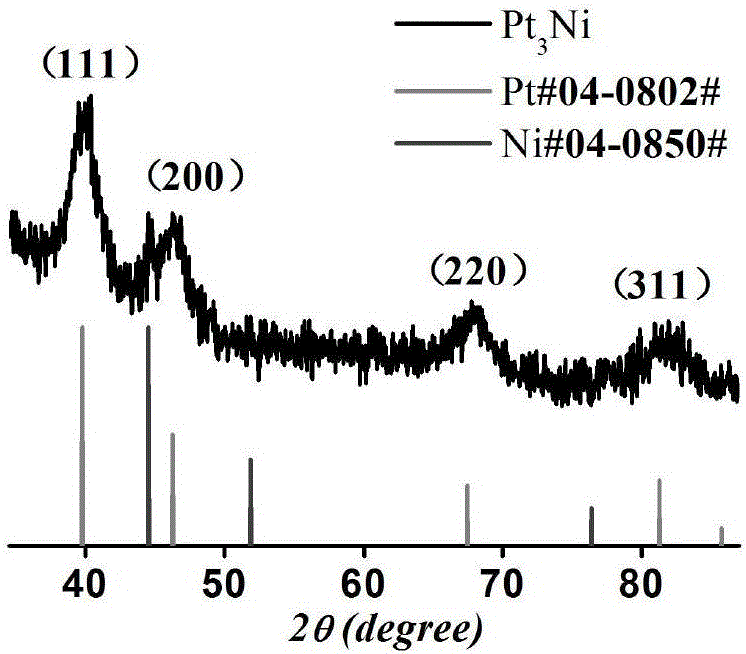

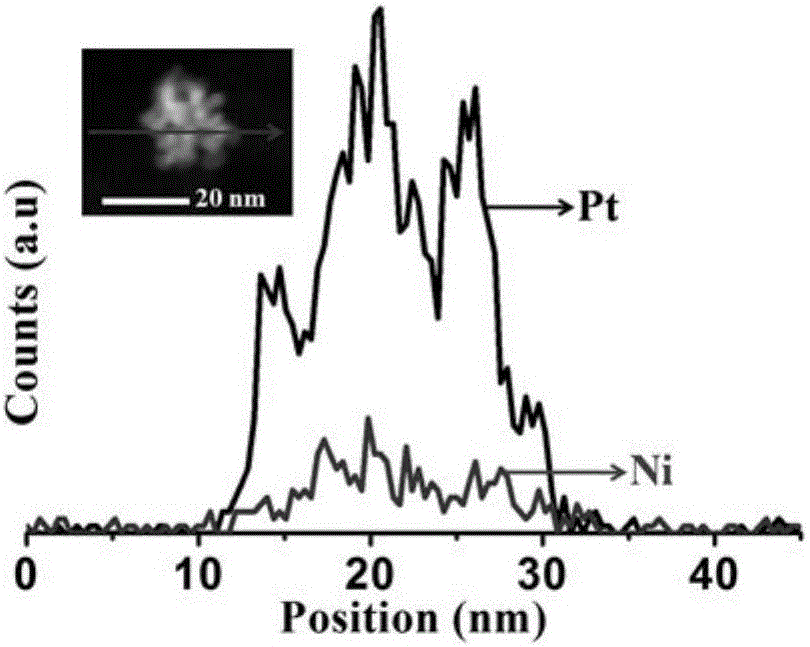

Image

Examples

Embodiment 1

[0017] The synthesis method of flower-like binary PtNi nanocrystals includes the following synthesis steps: (1) Add sodium chloride and PVP to dimethylacetamide, stir at room temperature for 5 minutes, and the mass ratio of sodium chloride to PVP is 1 :2; The amount of dimethylacetamide added needs to completely dissolve sodium chloride and PVP; (2) Add platinum acetylacetonate and nickel acetylacetonate precursors, metal salt precursors to the mixed solution obtained in step (1) The concentration is 0.1mol / L; stir at room temperature for 3 to 5 minutes; (3) add PVP to the mixed solution obtained in step (2), stir at room temperature for 10 to 30 minutes, the mass ratio of sodium chloride and PVP is 1: 5; (4) Transfer the mixed solution obtained in step (3) to an autoclave to react for 6 hours, the temperature is controlled at 180°C; (5) The product obtained in step (4) is cooled and washed, and after centrifugation, two Yuan PtNi nanocrystals.

Embodiment 2

[0019] The synthesis method of flower-like binary PtNi nanocrystals includes the following synthesis steps: (1) Add sodium chloride and PVP to dimethylacetamide, stir at room temperature for 6 minutes, and the mass ratio of sodium chloride to PVP is 1 :5; The amount of dimethylacetamide added needs to completely dissolve sodium chloride and PVP; (2) Add platinum acetylacetonate and nickel acetylacetonate precursors, metal salt precursors to the mixed solution obtained in step (1) The concentration is 0.5mol / L; stir at room temperature for 3 to 5 minutes; (3) add PVP to the mixed solution obtained in step (2), stir at room temperature for 10 to 30 minutes, the mass ratio of sodium chloride and PVP is 1: 7; (4) Transfer the mixed solution obtained in step (3) to an autoclave for reaction for 10 hours, the temperature is controlled at 150 ℃; (5) the product obtained in step (4) is cooled and washed, and after centrifugation, two Yuan PtNi nanocrystals.

Embodiment 3

[0021] The method for synthesizing flower-like binary PtNi nanocrystals includes the following synthesis steps: (1) Add sodium chloride and PVP to dimethylacetamide, stir at room temperature for 8 minutes, and the mass ratio of sodium chloride to PVP is 1 :4; The amount of dimethylacetamide added needs to completely dissolve sodium chloride and PVP; (2) Add platinum acetylacetonate and nickel acetylacetonate precursors, metal salt precursors to the mixed solution obtained in step (1) The concentration is 0.3mol / L; stir at room temperature for 3 to 5 minutes; (3) add PVP to the mixed solution obtained in step (2), stir at room temperature for 10 to 30 minutes, the mass ratio of sodium chloride and PVP is 1: 8; (4) The mixed solution obtained in step (3) is transferred to an autoclave for reaction for 2-12 hours, and the temperature is controlled at 200°C; (5) the product obtained in step (4) is cooled and washed, and then centrifuged. Obtain binary PtNi nanocrystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com