High-capacity organic lithium storage material and application thereof

An organic storage, high-capacity technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems that restrict the development and large-scale application of organic lithium storage materials, poor conductivity, and increased molecular weight of materials, and achieve excellent battery life. Chemical cycle stability, cost and cost reduction, good elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 provides an application of a high-capacity organic lithium storage material for making lithium battery electrodes, specifically:

[0026] (a) fully mix 5g maleic acid with 1g PVDF (commercially available), 4g acetylene black (commercially available) in 20g N-methylpyrrolidone (NMP, commercially available) and make electrode slurry;

[0027] (b) Coat the electrode slurry on the copper foil current collector (commercially available), and use 2MPa / cm after drying 2 The pressure is pressed, and after slitting, dry at 140°C and vacuum for 10 hours;

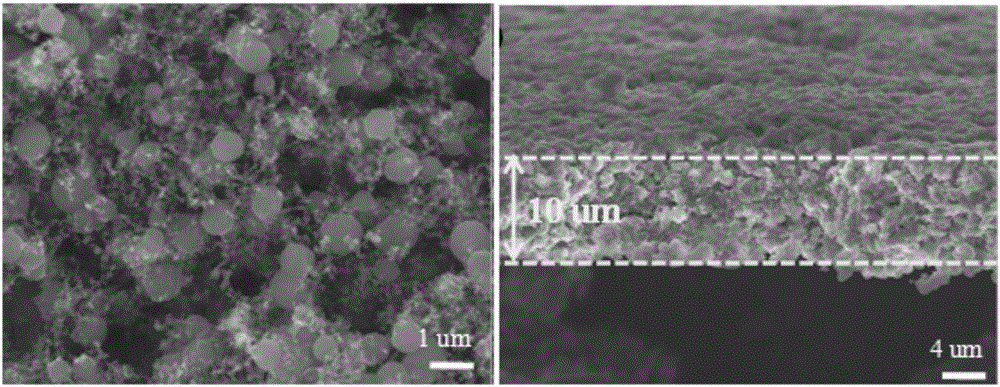

[0028] The SEM image of the prepared maleic acid electrode sheet is as follows figure 1 As shown, it can be seen that the maleic acid pellets and the acetylene black conductive agent are uniformly dispersed, and the thickness of the electrode is about 10 μm.

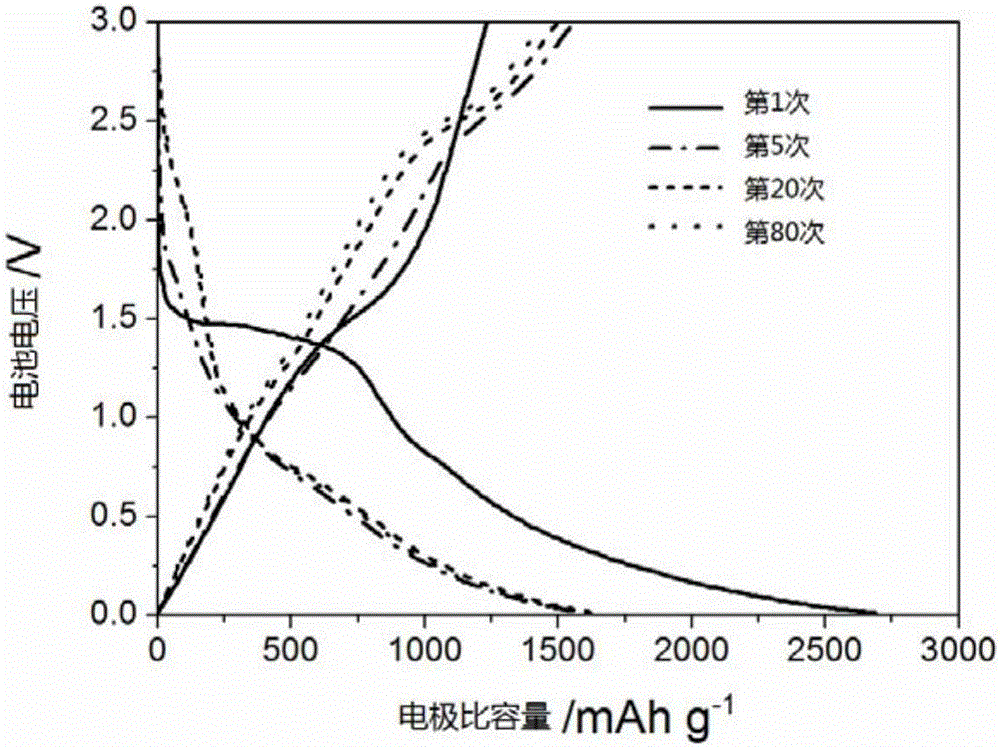

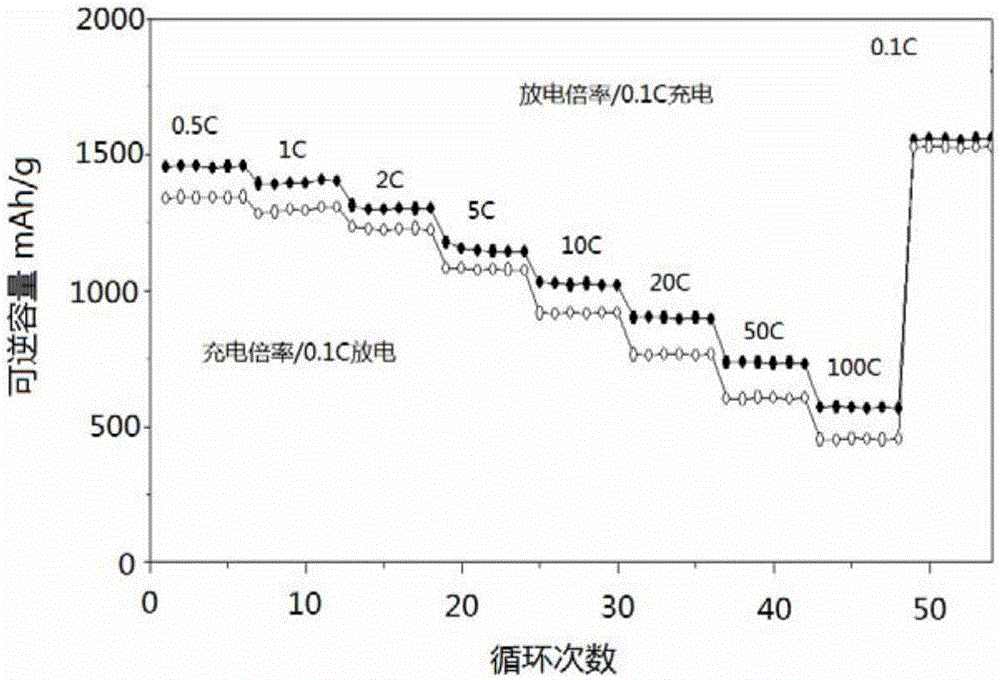

[0029]The maleic acid electrode will be made, according to the existing battery manufacturing method: the battery is assembled into a battery with lithium m...

Embodiment 2-12

[0031] Examples 2-12 respectively provide an application of a high-capacity organic lithium storage material, the difference is only in the type and quality of the organic lithium storage material, binder, conductive agent and dispersant, see Table 1 for details; wherein the insoluble The initial reversible capacity of the electrode made of iron maleate is slightly lower, which may be the reason for its more active electrochemical properties.

[0032] Table 1 Example 2-12 The formula ratio table for the application of high-capacity organic lithium storage materials

[0033]

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com