Smoking and processing method for bacon with low nitrite content

A low-nitrite and processing method technology, applied in the field of low-nitrite bacon smoking and processing, can solve the problems of unscientific demonstration of the smoking method, irregular smoking process conditions, no scientific basis for the effect, etc. Corruption, flavor health and safety, unique flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

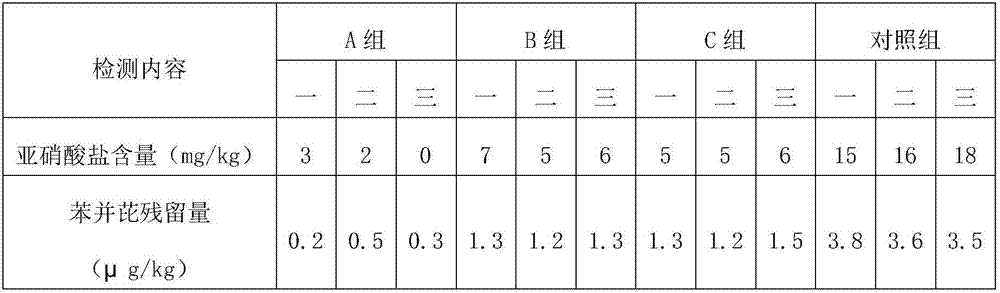

Examples

Embodiment 1

[0022] a. Raw material preparation: choose fresh pork belly, cut into 300g long strips, and the thickness of the meat strips should not exceed 4cm;

[0023] b. Preparation of ingredients: in parts by weight, take 7 parts of cinnamon, 2 parts of cloves, 6 parts of grass fruit, 19 parts of scallion and 9 parts of rosemary, mix and pulverize them, and then mix them with 2 parts of tea polyphenols to make seasoning powder ; By weight, get 10 parts of apple juice, 4 parts of holy maiden fruit juice and 0.4 part of honey, mix and make sauce;

[0024] c. Marinating: Spread 18g of salt, 6ml of cooking wine, and 12g of seasoning powder evenly on each piece of fresh meat, and then marinate at 5-10°C for 6 days. From the third day of marinating, turn it over once a day. Turn the meat that was originally located on the bottom layer to the upper layer, and the meat that was originally located on the upper layer to the bottom layer;

[0025] d. Heat baking: Drain the marinated meat pieces,...

Embodiment 2

[0030] a. Raw material preparation: choose fresh pork belly, cut into 250g long strips, and the thickness of the meat strips should not exceed 4cm;

[0031] b. Preparation of ingredients: in parts by weight, take 5 parts of cinnamon, 1 part of clove, 5 parts of grass fruit, 18 parts of scallion and 8 parts of rosemary, mix and pulverize them, and then mix them with 1 part of tea polyphenols to make seasoning powder ; In parts by weight, get 9 parts of apple juice, 3 parts of holy maiden fruit juice and 0.3 part of honey, and mix them evenly to make a sauce;

[0032] c. Marinating: Evenly spread 15g of salt, 6ml of cooking wine, and 10g of seasoning powder on each piece of fresh meat, and then marinate at 5-10°C for 5 days. From the third day of marinating, turn it over once a day. Turn the meat that was originally located on the bottom layer to the upper layer, and the meat that was originally located on the upper layer to the bottom layer;

[0033] d. Heat baking: Drain the ...

Embodiment 3

[0038] a. Raw material preparation: choose fresh pork belly, cut into 450g long strips, and the thickness of the meat strips should not exceed 4cm;

[0039] b. Preparation of ingredients: in parts by weight, take 8 parts of cinnamon, 2 parts of cloves, 8 parts of grass fruit, 20 parts of scallion and 10 parts of rosemary, mix and pulverize them, and then mix them with 2 parts of tea polyphenols to make seasoning powder ; In parts by weight, get 12 parts of apple juice, 5 parts of holy maiden fruit juice and 0.5 part of honey, and mix them evenly to make a sauce;

[0040] c. Marinating: Evenly spread 30g of salt, 8ml of cooking wine, and 15g of seasoning powder on each piece of fresh meat, and then marinate at 5-10°C for 8 days. From the third day of marinating, turn it over once a day. Turn the meat that was originally located on the bottom layer to the upper layer, and the meat that was originally located on the upper layer to the bottom layer;

[0041] d. Heat baking: Drain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com