Phosphorus-nitrogen type fire retardant and preparation method thereof

A flame retardant, diaminodiphenylmethane technology, applied in the field of flame retardants and their preparation, can solve problems such as hazards, flammability of polymer materials, etc., and achieve the effects of wide use, convenient operation, and improved flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

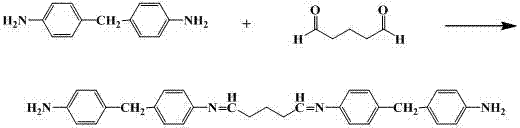

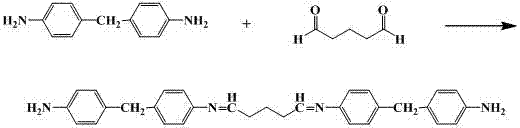

Image

Examples

example 1

[0025] Step 1: Add 3.97g of 4,4'-diaminodiphenylmethane and 1g of glutaraldehyde to a 250ml three-necked flask equipped with a magnetic stirrer, a reflux condenser, a thermometer, a nitrogen inlet tube and an exhaust gas absorption device, and add 20ml Dichloromethane was used as a solvent, nitrogen gas was passed through, the temperature was raised to 30° C., and then reacted for 5 hours. After the reaction was completed, it was cooled to room temperature, and the intermediate was obtained by suction filtration, washing, and drying.

[0026] Step 2: Add 4.61g of intermediates and 4.32g of DOPO to a 250ml three-neck flask equipped with a magnetic stirrer, reflux condenser, thermometer, nitrogen inlet tube and tail gas absorption device, add 20ml of toluene as a solvent, and feed nitrogen to raise the temperature After reaching 50°C, react for 5 hours. After the reaction, cool to room temperature, filter with suction, wash, and dry to obtain a phosphorus and nitrogen type flame ...

example 2

[0028] Step 1: Add 4.36g of 4,4'-diaminodiphenylmethane and 1g of glutaraldehyde to a 250ml three-neck flask equipped with a magnetic stirrer, a reflux condenser, a thermometer, a nitrogen inlet tube and an exhaust gas absorption device, and add 30ml Ethanol was used as a solvent, and nitrogen gas was passed through, and the temperature was raised to 30° C. and then reacted for 6 hours. After the reaction was completed, it was cooled to room temperature, and the intermediate was obtained by suction filtration, washing, and drying.

[0029] Second step: add 4.61g intermediate and 4.75g DOPO to the 250ml there-necked flask equipped with magnetic stirrer, reflux condenser, thermometer, nitrogen inlet pipe and tail gas absorption device, add 40ml xylene as solvent, feed nitrogen, Raise the temperature to 60°C and react for 6 hours. After the reaction, cool to room temperature, filter with suction, wash and dry to obtain a phosphorus and nitrogen type flame retardant.

example 3

[0031] Step 1: Add 4.76g of 4,4'-diaminodiphenylmethane and 1g of glutaraldehyde to a 250ml three-neck flask equipped with a magnetic stirrer, a reflux condenser, a thermometer, a nitrogen inlet tube and an exhaust gas absorption device, and add 30ml Acetonitrile was used as a solvent, and nitrogen gas was passed through, and the temperature was raised to 50° C. and then reacted for 6 hours. After the reaction was completed, it was cooled to room temperature, and the intermediate was obtained by suction filtration, washing, and drying.

[0032] Second step: add 4.61g intermediate and 5.18g DOPO to the 250ml there-necked flask equipped with magnetic stirrer, reflux condenser, thermometer, nitrogen inlet pipe and tail gas absorption device, add 30ml xylene as solvent, feed nitrogen, Raise the temperature to 70°C and react for 7 hours. After the reaction, cool to room temperature, filter with suction, wash and dry to obtain a phosphorus and nitrogen type flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com