Natural gas hydrate replacement method for combining hot seawater injection methane extraction enhancement and carbon dioxide storage

A carbon dioxide and hydrate technology, which is applied in the fields of mining fluids, earthwork drilling, climate sustainability, etc., can solve the problems of low carbon dioxide sequestration rate and replacement rate, unfavorable carbon dioxide diffusion, and large energy dissipation of thermal shock method, etc., to achieve The effect of reducing the greenhouse effect, promoting diffusion, and increasing the storage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

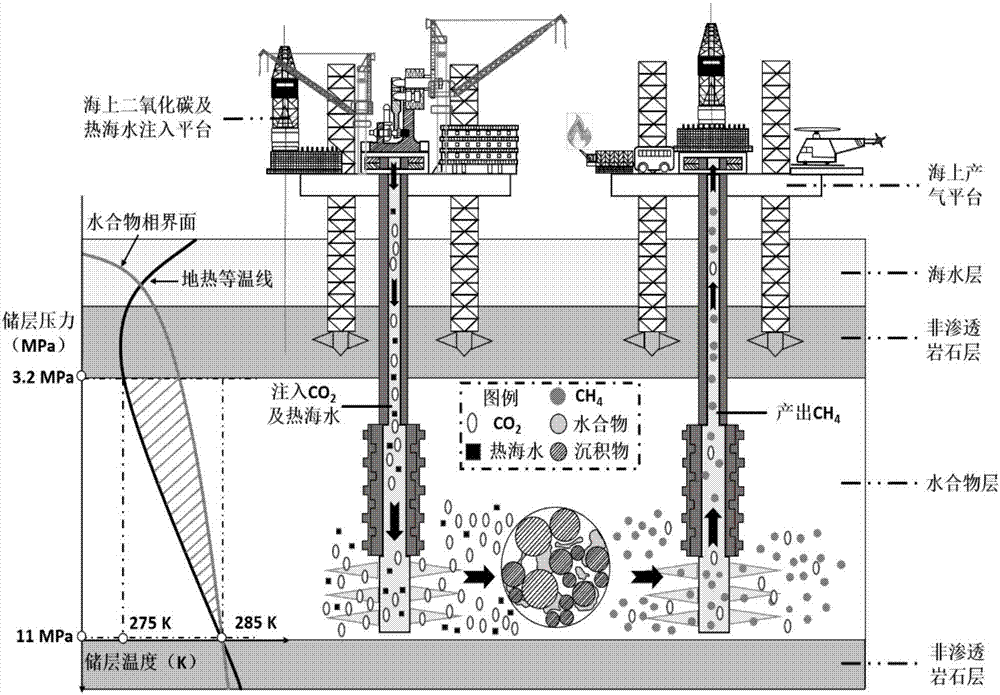

[0026] as attached figure 1 As shown, gas hydrate reservoirs often exist in marine sediments at 1200-1500 meters below sea level, and the temperature and pressure conditions are 275-285K, 3.2-11MPa. The hydrate reservoir at 1,200 meters below sea level, with a reservoir temperature of 275K and a reservoir pressure of 3.2MPa is now selected as the target area to describe the standardized mining process and describe the optimal conditions.

[0027] (1) Build offshore injection platform and gas production platform, if attached figure 1 As shown, carbon dioxide and hot seawater injection wells and methane gas production wells are drilled. After the drilling is completed, the pressure of the hydrate reservoir decreases, and the gas hydrate around the wellbore is in a metastable state.

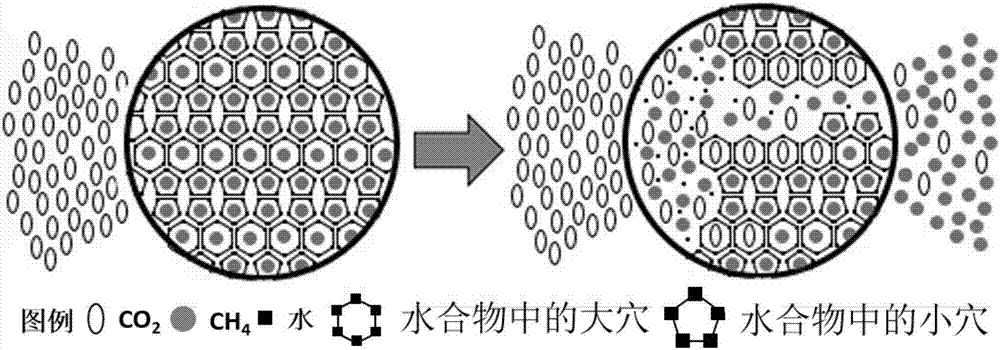

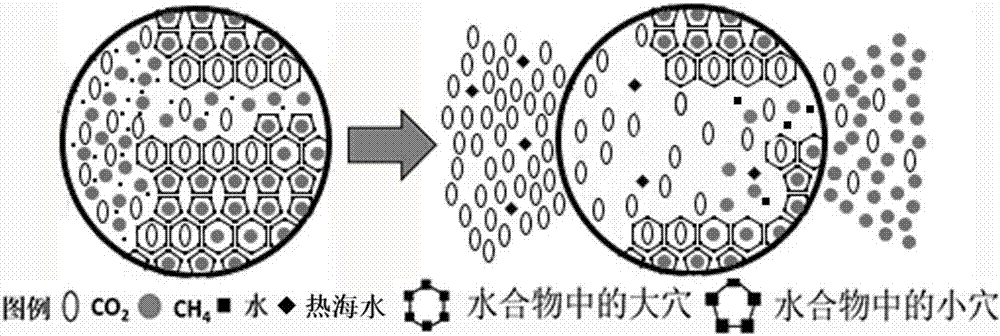

[0028] (2) As attached figure 2 As shown, carbon dioxide is injected into the hydrate reservoir from the carbon dioxide and hot seawater injection well, and the reservoir pressure is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com