Preparation of a Biomass Emulsion Separation Membrane and Its Application in Selective Emulsion Separation

An emulsion separation and biomass technology, which is applied in the fields of composite membrane materials and oil-water separation, can solve the problems of difficult realization of responsive copolymers or responsive surface creation and limitations of large-scale preparation, and achieves low cost, convenient operation and high separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the preparation of biomass emulsion separation membrane

[0031] Coprinus comatus is dried and crushed to a particle size of 0.1-0.3 μm; stirred in 2.0-4.0 mol / L NaOH solution for 120-150 min, filtered, and dried;

[0032] Fully disperse the alkali-treated Coprinus comatus powder and sodium alginate in water respectively to form Coprinus comatus powder solution and sodium alginate solution, and then mix the two solutions. In the mixed solution, the concentration of Coprinus comatus powder is 6.0 ~ 8.0 mg / mL, the concentration of sodium alginate is 8 ~ 12 mg / mL; then the mixed solution was stirred and reacted at 20 ~ 30°C for 10 ~ 20 min to obtain the reaction solution;

[0033] A microporous filter membrane is fixed in the vacuum filtration device, and the microporous filter membrane is a PVDF filter membrane with a pore size of 0.40-0.45 μm. Add the reaction liquid to the microporous filter membrane, then vacuum filter under the pressure of 0.07 ~ 0.09 ...

Embodiment 2

[0034] Embodiment 2, biomass emulsion separation membrane separates kerosene emulsion in water

[0035] Preparation of kerosene-in-water emulsion: Mix surfactant, kerosene and water at a ratio of 0.05: (1-5): (100-500), and stir at 600-1500 rpm for 3-6 h. Among them, the surfactant is Tween 80 (Tween80), and the oil is kerosene. The particle size distribution figure of the prepared water-in-kerosene emulsion is shown in Figure 4 (a). It can be seen from the figure that the particle size of the kerosene-in-water emulsion is 200-1300 nm, which belongs to the micro / nano-scale stable emulsion.

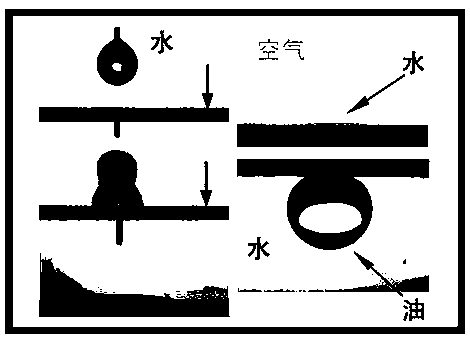

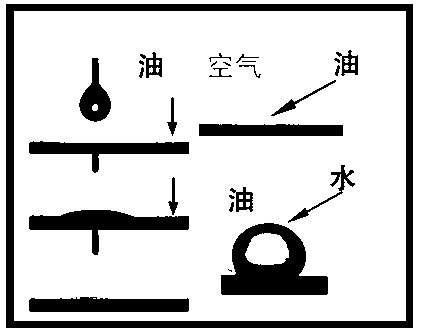

[0036] Emulsion separation experiment test: After the emulsion separation membrane is fixed on the suction filtration device, it is pre-soaked with water. After being completely infiltrated, pour the kerosene-in-water emulsion prepared above onto the emulsion separation membrane in the suction filtration device for suction filtration. As the suction filtration proceeds, the emulsion i...

Embodiment 3

[0038] Embodiment 3, separation of water-in-kerosene emulsion by biomass emulsion separation membrane

[0039] Preparation of water-in-kerosene emulsion: Mix surfactant, water and kerosene at a ratio of 0.05: (1-5): (100-500), and stir at 600-1500 rpm for 3-6 h. Among them, the surfactant is Span 80 (Span80), and the oil is kerosene. The particle size distribution figure of the prepared water-in-kerosene emulsion is shown in Figure 4 (b). It can be seen from the figure that the prepared water-in-kerosene emulsion has a particle size of 200-1300 nm, which belongs to the micro / nano-scale stable emulsion.

[0040] Emulsion separation experiment test: After the emulsion separation membrane is fixed on the suction filtration device, it is pre-soaked with kerosene. After being completely infiltrated, the above-mentioned water-in-kerosene emulsion is poured onto the biomass emulsion separation membrane in the suction filtration device for suction filtration. As the suction filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com