Preparation method and device for preparing microspheres through gas

A preparation device and gas preparation technology, applied in the polymer field, can solve the problems of complex separation steps, complex preparation process, not green enough, etc., and achieve the effects of rapid preparation, simple method and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

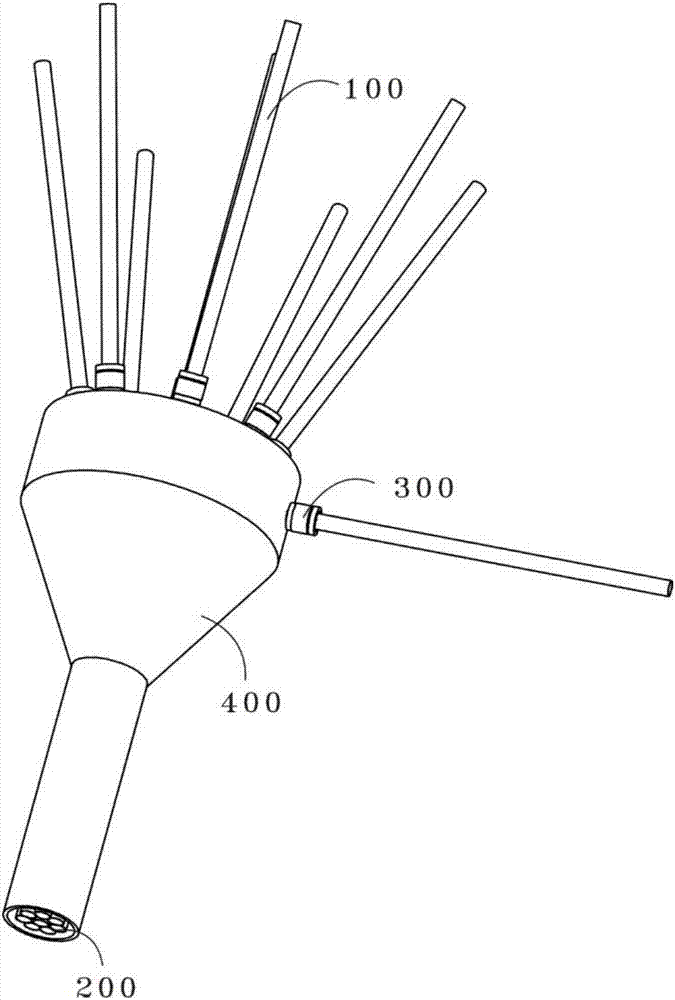

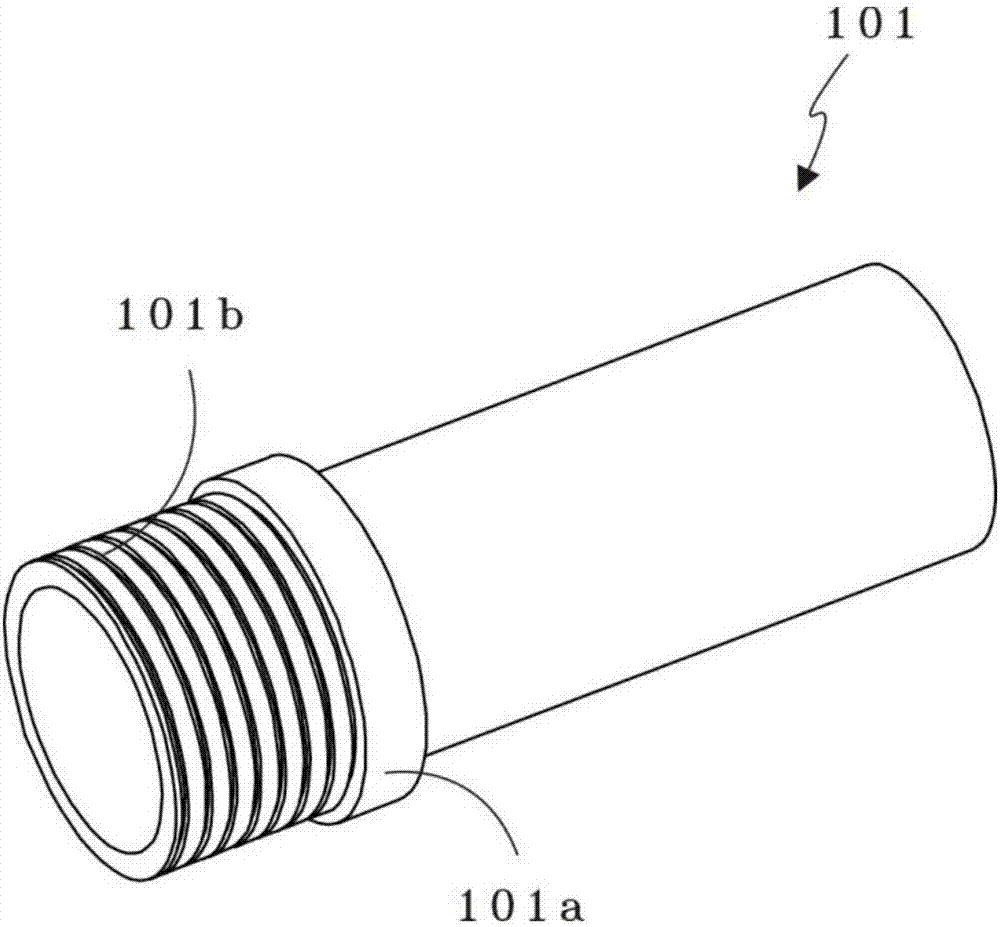

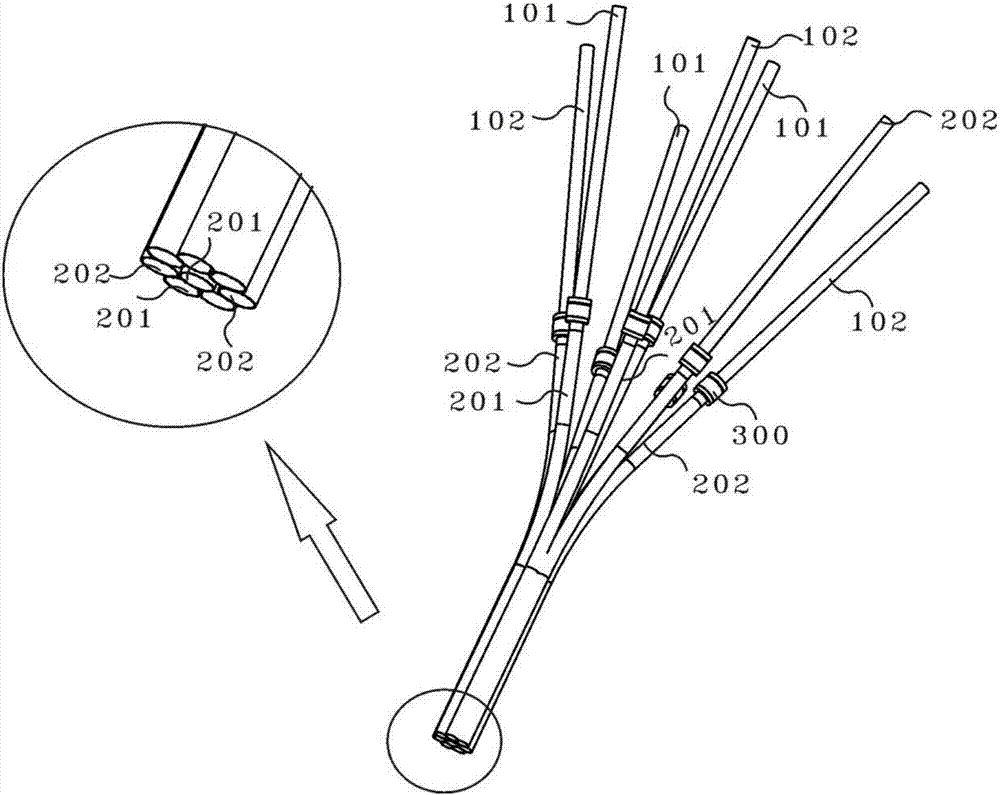

[0038] Such as Figure 14 and see Figure 1-13 , the invention provides a preparation method utilizing gas to prepare microspheres, which comprises three steps:

[0039] The first step is to push the protective gas into the preparation device;

[0040] In the second step, the solution is dripped into the preparation device;

[0041] In the third step, the dripped solution is solidified into balls in the solution of the receiving device, and the target microspheres are obtained.

[0042] The first step is to introduce protective gas into the preparation device, where the protective gas can be nitrogen, and the protective gas is transferred from the third one-way pipe 103 of the preparation device to the reducing pipe part 200, and the flow rate of the protective gas is 0.2-0.8 L / min.

[0043] Said solution in the second step can be the mixed solution of pure sodium alginate and 0.2% ferric oxide solution and 2% sodium alginate solution, here in 2% sodium alginate solution, ...

Embodiment 1

[0048] In the first embodiment of the present invention, the method for preparing sodium alginate homogeneous microspheres using gas comprises three steps,

[0049] First, prepare sodium alginate microspheres. The preparation of sodium alginate microspheres includes preparing sodium alginate solution, preparing calcium chloride solution, and preparing the sodium alginate microspheres with a device for preparing sodium alginate homogeneous microspheres.

[0050] When preparing the sodium alginate solution, first prepare sodium alginate solutions of different concentrations. The specific operation is to weigh 0.1g, 0.5g, 1g, 2g, and 3g of sodium alginate, respectively, and dissolve them in 50ml of distilled water to obtain different concentrations. concentration of sodium alginate solution, and then add ferric oxide (made into 0.2% ferric oxide solution), the significance of adding ferric oxide here is: in order to characterize the successful preparation of microspheres. By obs...

Embodiment 2

[0056] Second embodiment of the present invention, utilize gas to prepare the method for chitosan homogeneous microsphere, comprise three steps:

[0057] First, chitosan microspheres were prepared. The preparation of chitosan microspheres includes preparing chitosan solution, preparing sodium hydroxide solution, and preparing the chitosan microspheres with a device for preparing chitosan homogeneous microspheres.

[0058] When configuring the chitosan solution, first configure chitosan solutions with different concentrations. The specific operation is to weigh 0.1g, 0.5g, 1g, 2g, and 3g of sodium alginate, respectively, and dissolve them in 60ml of 2% acetic acid aqueous solution. Promptly obtain the chitosan solution of different concentrations, then respectively add ferric oxide nano-microspheres (being made into 0.2% ferric oxide nano-microspheres solution), the meaning of adding nanometer ferric oxide microspheres here is: for Characterize the successful preparation of mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com