Preparation method and product of bio-carbon composite material

A composite material and biochar technology, which is applied in the direction of carbon preparation/purification, etc., can solve the problems that it is difficult to prepare highly water-absorbent biochar materials, and needs to be improved, so as to facilitate repair, low cost, and easy industrialization and commercialization The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of biochar composite material, comprises the steps:

[0026] (1) Wheat straw is used as the main ingredient, and at least two kinds of corn stalks, rice stalks and cotton stalks are used as auxiliary materials, and the mass percentages of each component are: 50-60% of wheat stalks, and no more than 36% of corn stalks %, rice stalk is not higher than 28%, cotton stalk is not higher than 16%;

[0027] (2) Drying the selected main and auxiliary materials, then pulverizing, mixing the main and auxiliary materials, and sealing and storing for a period of time;

[0028] (3) Carrying out anaerobic pyrolysis of the mixture obtained in the step (2) under the protection of an inert gas, and then cooling to room temperature in an inert gas atmosphere;

[0029] Based on the above method, a variety of agricultural biomass is selected as a raw material and subjected to anaerobic pyrolysis treatment after crushing to obtain a biocha...

Embodiment 1

[0033] The biochar composite material was prepared according to the above preparation method, and the specific parameters were as follows: Four agricultural biomasses of wheat straw, corn stalk, rice stalk and cotton stalk were selected as raw materials, and the mixed mass percentages were 50% of wheat straw, 24% of corn stalk, Rice stalk 18% and cotton stalk 8%; the four agricultural biomasses of wheat stalk, corn stalk, rice stalk and cotton stalk are dried to a water content of 6%-10%, and the particle size of the raw material after crushing and screening is below 0.25mm , sealed and stored at 25°C for 30 days, the pyrolysis temperature was 550°C, the pyrolysis reaction time was 30min, and the oxygen-free protective gas N 2 The air velocity is 0.32m / s. In this way, biochar composite materials were prepared.

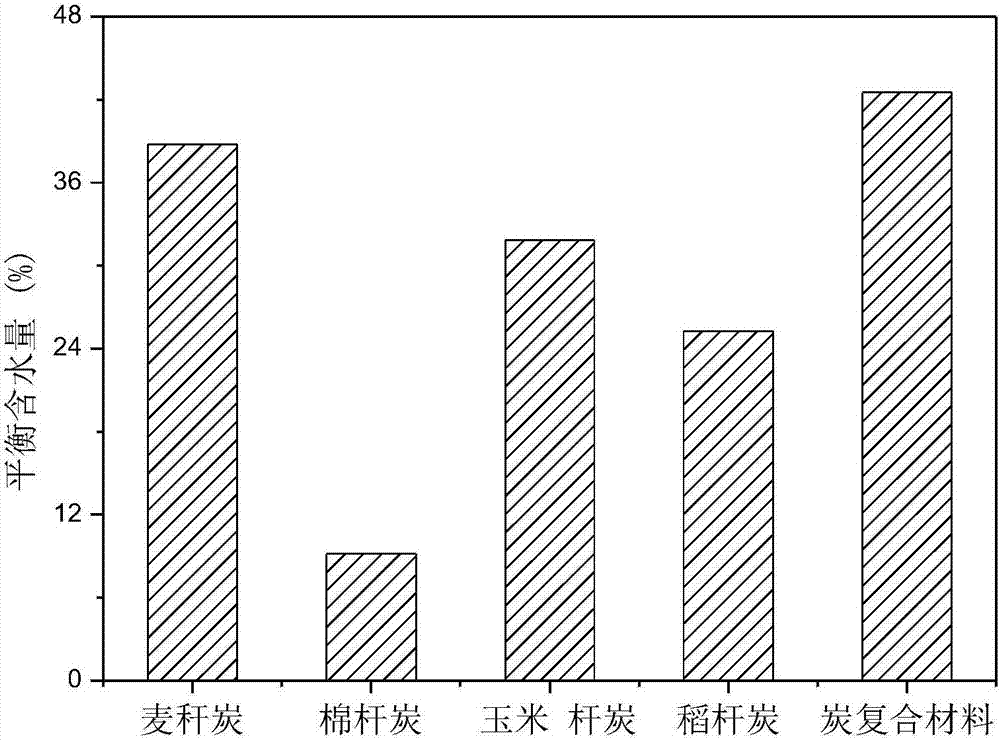

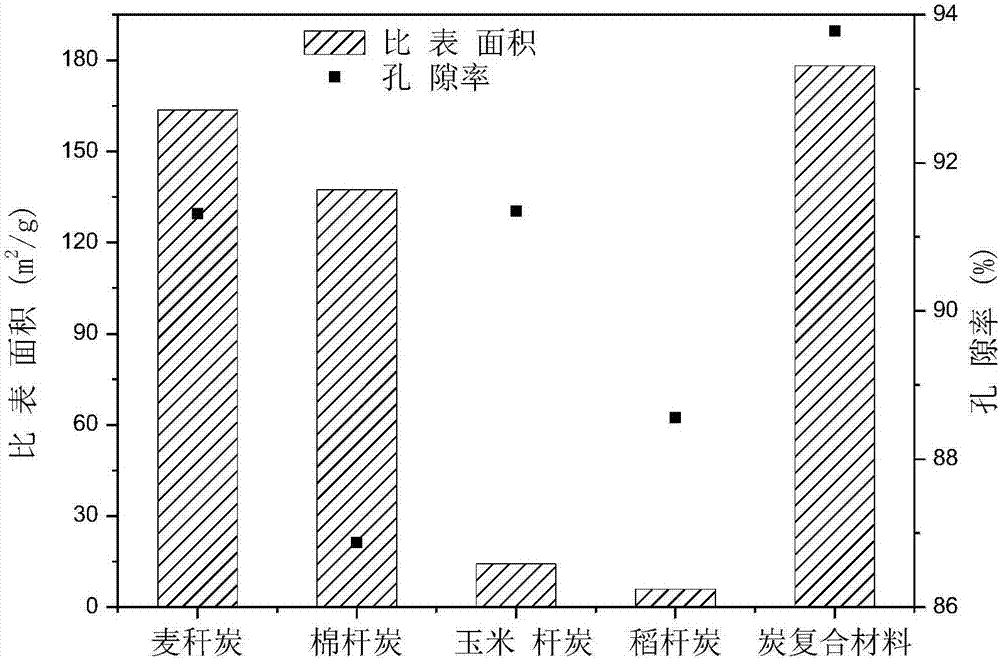

[0034] For the obtained above-mentioned biochar composite material, figure 1 and figure 2 A comparison of three performance parameters of the biochar composite mat...

Embodiment 2

[0036] The biochar composite material was prepared according to the above preparation method, and the specific parameters were as follows: Three kinds of agricultural biomass of wheat straw, corn stalk and cotton stalk were selected as raw materials, and the mixed mass percentages were 55% of wheat straw, 36% of corn stalk and 9% of rice stalk. %; wheat straw, corn stalk and rice straw are three kinds of agricultural biomass dried to a moisture content of 6%-10%. The temperature is 500°C, the pyrolysis reaction time is 40min, and the oxygen-free protective gas N 2 The air velocity is 0.25m / s. In this way, biochar composite materials were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com