Nanosheet prepared from transition metal oxide nano particles and preparation method thereof

A transition metal, nanoparticle technology, applied in nanotechnology, nickel oxide/nickel hydroxide, cobalt oxide/cobalt hydroxide, etc., can solve the problems of complex process, narrow application range, large particles, etc., and achieves simple operation and low cost. Inexpensive and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

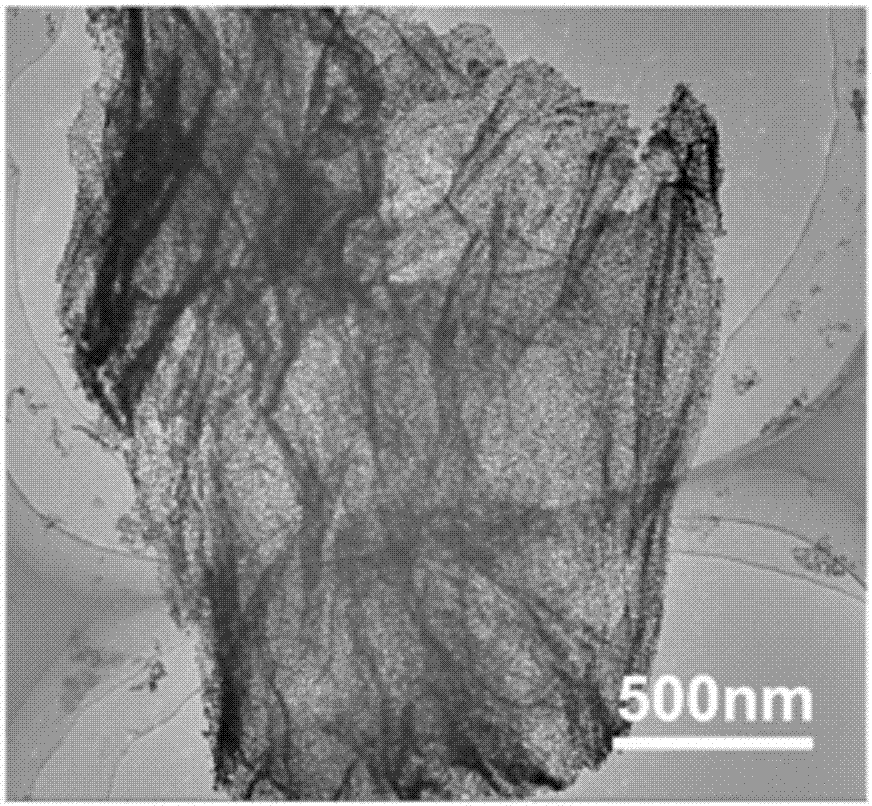

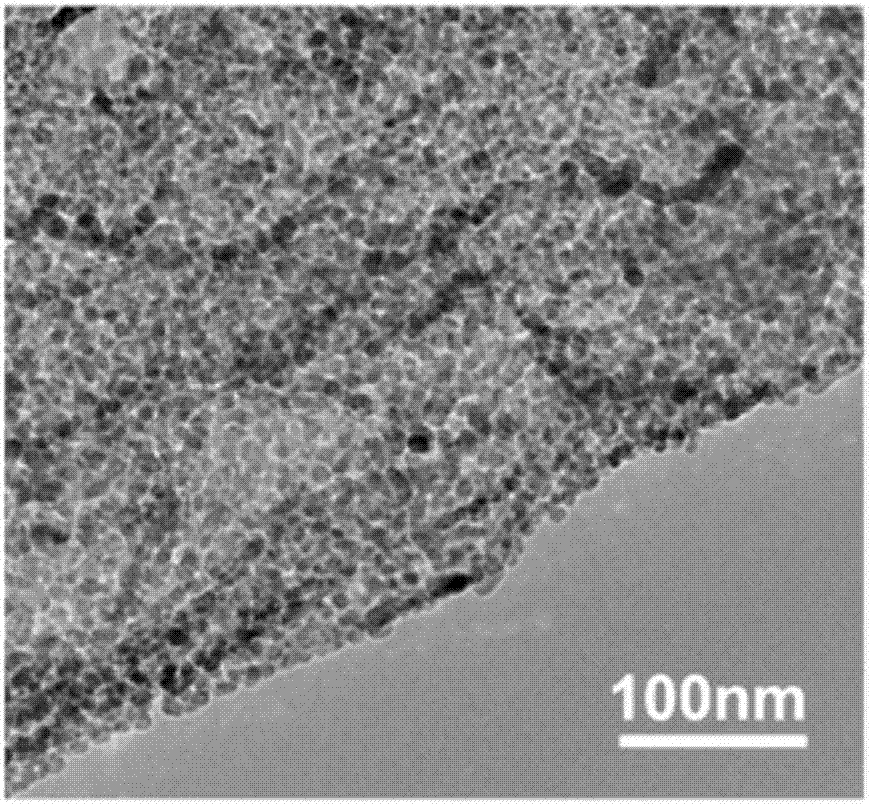

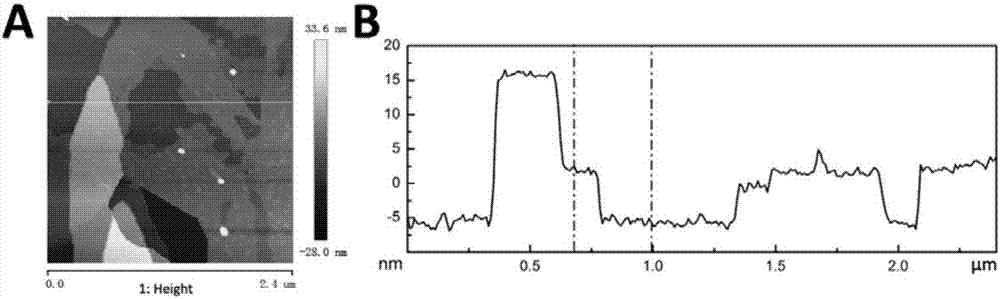

specific Embodiment approach 1

[0020] Specific embodiment one: in the present embodiment, the nano sheet that is made of tricobalt tetroxide nanoparticle is to use cobalt phthalocyanine as metal source, with graphene oxide as template, be the hydrazine hydrate of 20% (mass) as reducing agent with water content, with Distilled water is used as a medium and finally obtained by calcination; in terms of weight percentage, the ratio of raw materials is as follows: 0.22% graphene oxide, 0.90% cobalt phthalocyanine, 8.99% hydrazine hydrate and 89.89% distilled water; specific preparation method It is carried out according to the following steps: Step 1, adding graphene oxide into distilled water, ultrasonically vibrating for 30min at an ultrasonic frequency of 40kHz, adding cobalt phthalocyanine, and continuing ultrasonically vibrating for 1h at an ultrasonic frequency of 40kHz; Step 2 , Then add hydrazine hydrate, stir at 40°C for 1h, centrifuge and dry at 80°C; step 3, put it in a muffle furnace, calcine at a con...

specific Embodiment approach 2

[0033] Specific embodiment two: In this embodiment, the nanosheets made of ferric oxide nanoparticles are iron phthalocyanine as the metal source, graphene oxide as the template, and hydrazine hydrate with a water content of 20% (mass) as the reduction agent. The agent is obtained by calcination with distilled water as the medium; in terms of weight percentage, the ratio of raw materials is as follows: 0.46% graphene oxide, 1.94% iron phthalocyanine, 10.43% hydrazine hydrate and 87.17% distilled water; The specific preparation method is carried out according to the following steps: Step 1. Add graphene oxide into distilled water, ultrasonically vibrate for 50 minutes under the condition of ultrasonic frequency of 40 kHz, add iron phthalocyanine, and continue ultrasonic vibration for 4 hours under the condition of ultrasonic frequency of 40 kHz ;Step 2, then add hydrazine hydrate, stir at 20°C for 2h, centrifuge and dry at 80°C; Step 3, put it in a muffle furnace, and calcine at...

specific Embodiment approach 3

[0037] Specific embodiment three: in the present embodiment, the nanosheet made of nickel oxide nanoparticles is nickel phthalocyanine as a metal source, graphene oxide as a template, and hydrazine hydrate with a water content of 20% (mass) as a reducing agent, Using distilled water as a medium, it is finally obtained by calcination; in terms of weight percentage, the ratio of raw materials is as follows: 0.36% graphene oxide, 1.64% nickel phthalocyanine, 9.43% hydrazine hydrate and 88.57% distilled water; specific preparation The method is carried out according to the following steps: step 1, adding distilled water into graphene oxide, ultrasonically vibrating for 40 minutes under the condition of ultrasonic frequency of 40 kHz, adding nickel phthalocyanine, and continuing ultrasonic vibration for 2 hours under the condition of ultrasonic frequency of 40 kHz; step 2 , then add hydrazine hydrate, stir at 30°C for 1.5h, centrifuge and dry at 80°C; step 3, put it in a muffle furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com