Sewage treatment method

A sewage treatment method and adsorption treatment technology, applied in the direction of adsorption water/sewage treatment, magnetic field/electric field water/sewage treatment, chemical instruments and methods, etc., can solve problems such as hindering popularization and application, complicated equipment, complicated and cumbersome operation, etc. Achieve good control of molecular concentration and interaction, reduce energy consumption, and fine internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A sewage treatment method, comprising the steps of:

[0033] 1) Prepare porous composite material;

[0034] 2) Put the above-mentioned porous composite functional material in the sewage to adsorb the organic pollutants in the water body; use the large-density microporous structure of the particles and the hydrophobicity of PDMS to absorb common water body pollutants such as organic solvents toluene, sulfide, Thiophenol and thioether, etc.;

[0035] 3) The magnetic particles adsorbed with pollutants are first recovered by an external magnetic field, and then the magnetic field strength is increased to separate the magnetic particles from the pollutants.

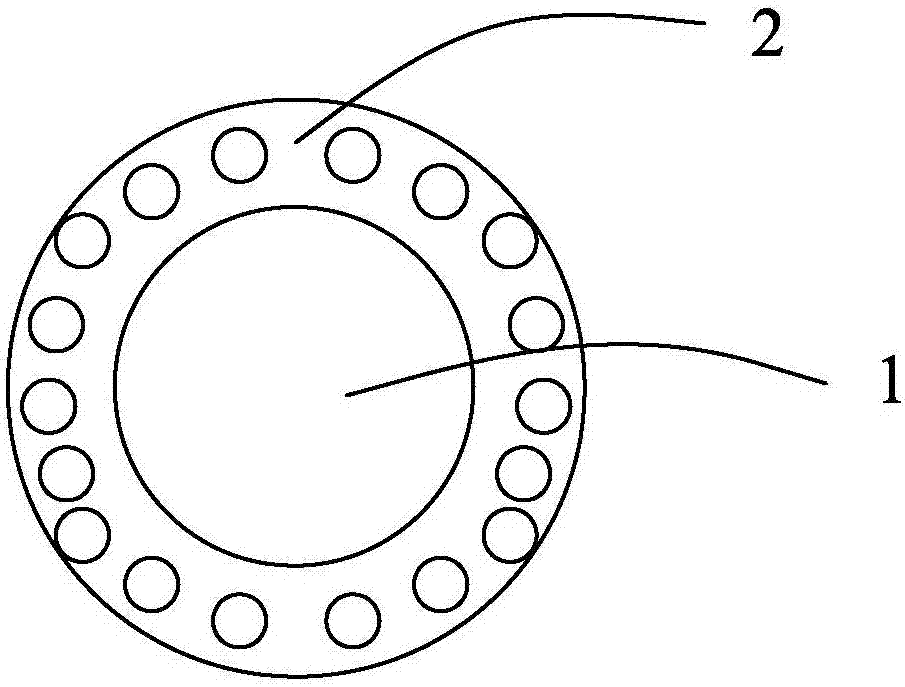

[0036] The porous composite material includes a magnetic core 1 and a porous shell 2 coated on the outside of the core, and the porous composite material is prepared by the following steps:

[0037] 1) Prepare a microfluidic chip in which channels with a two-stage copolymerization flow structure are connected in series ...

Embodiment 2

[0043] Sewage treatment method is the same as embodiment one.

[0044] The porous composite material includes a magnetic core 1 and a porous shell 2 coated on the outside of the core, and the porous composite material is prepared by the following steps:

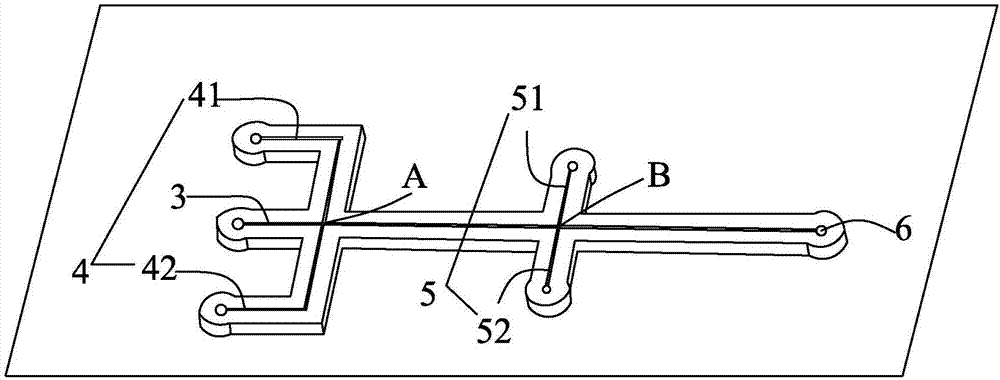

[0045] 1) Prepare a microfluidic chip in which channels with a two-stage copolymerization flow structure are connected in series by a soft photolithography method; the microfluidic chip includes an inner channel 3, a middle channel 4, an outer channel 5 and an outflow channel 6; The middle channel 4 includes a first middle channel 41 and a second middle channel 42; the outer channel 5 includes a first outer channel 51 and a second outer channel 52; the material of the microfluidic chip is an acrylic plate, and the length of the chip is 10 cm. 500μm wide and 500μm high;

[0046] 2) prepare three kinds of mutually immiscible liquid phases, as inner phase, intermediate phase and outer phase, prepare double emulsion template; De...

Embodiment 3

[0050] Sewage treatment method is the same as embodiment one.

[0051] The porous composite material includes a magnetic core 1 and a porous shell 2 coated on the outside of the core, and the porous composite material is prepared by the following steps:

[0052] 1) Prepare a microfluidic chip in which channels with a two-stage copolymerization flow structure are connected in series by a soft photolithography method; the microfluidic chip includes an inner channel 3, a middle channel 4, an outer channel 5 and an outflow channel 6; The middle channel 4 includes a first middle channel 41 and a second middle channel 42; the outer channel 5 includes a first outer channel 51 and a second outer channel 52; the material of the microfluidic chip is an acrylic plate, and the length of the chip is 10 cm. 500μm wide and 500μm high;

[0053] 2) prepare three kinds of mutually immiscible liquid phases, as inner phase, middle phase and outer phase, prepare double emulsion template; Describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com