Anti-seepage anti-corrosion cement-clay solidifying slurry and preparation method thereof

A technology of clay slurry and clay, which is applied in the field of grouting materials and geotechnical engineering materials in the discipline of water conservancy and hydropower, can solve the problems that clay slurry is difficult to consolidate and the fusion of consolidation boundaries is poor, and achieves less loss, good deformation coordination, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

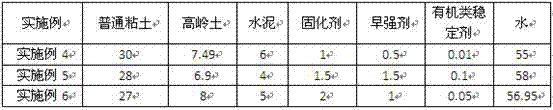

Examples

Embodiment 1

[0040] For the anti-seepage and anti-corrosion cement-clay solidified slurry of Example 1, the ratio of raw materials (100 parts as base) is 25 parts of ordinary clay (dry soil) with a clay content of 26.2%, 6.5 parts of kaolin, and ordinary silicate with P.O 42.5 6 parts of cement, 1.8 parts of curing agent (activated silica, class II fly ash, lime), 0.65 parts of early strength agent (calcium chloride, triethanolamine, sodium silicate, calcium sulfate, potassium aluminum sulfate), organic stabilizer Agent (polyacrylamide) 0.05 parts and water 60 parts.

[0041] The components of the parts by weight of the material (100 parts as the base) are as follows:

[0042] Ordinary clay (dry soil) 25 parts

[0043] Kaolin 6.5 parts

[0044] P. O 42.5 Ordinary Portland cement 6 parts

[0045] Active silica 0.3 parts

[0046] Class II fly ash 1 part

[0047] Lime 0.5 parts

[0048] Calcium chloride 0.2 parts

[0049] Triethanolamine 0.05 part

Embodiment 2

[0058] For the anti-seepage and anti-corrosion cement-clay solidified slurry of Example 2, the ratio of raw materials (100 parts as the base) is 25 parts of ordinary clay (dry soil) with a clay content of 26.2%, 6.5 parts of kaolin, and ordinary silicate with P.O 42.5 5 parts of cement, 2.5 parts of curing agent (activated silica, class II fly ash, lime), 0.95 parts of early strength agent (calcium chloride, triethanolamine, sodium silicate, calcium sulfate), organic stabilizer (polypropylene amide) 0.05 parts and water 60 parts.

[0059] The components of the parts by weight of the material (100 parts as the base) are as follows:

[0060] Ordinary clay (dry soil) 25 parts

[0061] Kaolin 6.5 parts

[0062] P.O 42.5 Ordinary Portland Cement 5 parts

[0063] Active silica 0.5 parts

[0064] Class II fly ash 1.5 parts

[0065] Lime 0.5 parts

[0066] Calcium chloride 0.2 parts

[0067] Triethanolamine 0.05 part

[0068] Sodium silicate 0.2 parts

[0069] Calcium sulfate...

Embodiment 3

[0075] For the anti-seepage and anti-corrosion cement-clay solidified slurry of Example 3, the ratio of raw materials (100 parts as base) is 25 parts of ordinary clay (dry soil) with a clay content of 26.2%, 6.5 parts of kaolin, and ordinary silicate with P.O 42.5 3.4 parts of cement, 3.5 parts of curing agent (activated silica, class II fly ash, lime), 1.5 parts of early strength agent (calcium chloride, triethanolamine, sodium silicate, calcium sulfate, potassium aluminum sulfate), organic stabilizer Agent (polyacrylamide) 0.1 part and water 60 parts.

[0076] The components of the parts by weight of the material (100 parts as the base) are as follows:

[0077] Ordinary clay (dry soil) 25 parts

[0078] Kaolin 6.5 parts

[0079] P.O 42.5 ordinary portland cement 3.4 parts

[0080] Active silica 0.5 parts

[0081] Class II fly ash 2 parts

[0082] 1 part lime

[0083] Calcium chloride 0.2 parts

[0084] Triethanolamine 0.05 part

[0085] Sodium silicate 0.5 parts

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com