Separation method of acetophenone from 1-phenethyl alcohol

A separation method and acetophenone technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, separation/purification of carbonyl compounds, etc., can solve the problem of unsuitability for industrial-scale production, low product purity, and long operation cycle. and other problems, to achieve the effect of high product recovery rate, stable chemical properties, and less three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

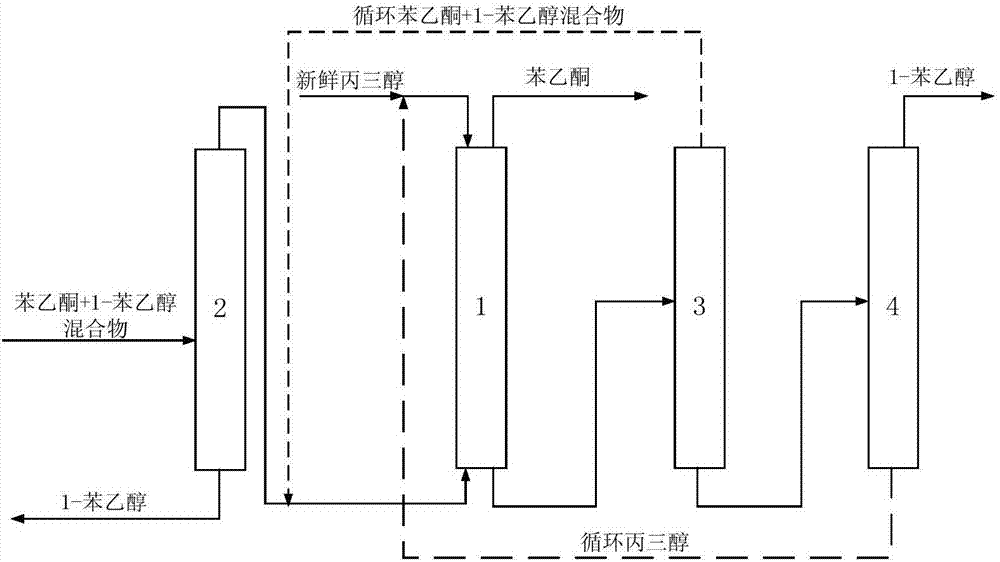

[0026] A method for separating acetophenone and 1-phenylethanol, such as figure 1 As shown, including the following steps:

[0027] (1) The mixture of acetophenone with a mass percentage of 28% acetophenone and 1-phenylethanol is fed into the first distillation tower 2 for initial distillation, and the top of the tower obtains a mass percentage of acetophenone of 52 % Of the mixture of acetophenone and 1-phenylethyl alcohol, 1-phenylethyl alcohol product is obtained at the bottom of the tower (sample analysis, purity of 99.4%), the operating pressure of the first distillation tower 2 is 0.1MPa, the temperature of the top and bottom of the tower Are the boiling point of the system;

[0028] (2) The tower top mixture obtained in step (1) is pumped into the bottom of the extraction tower 1, and the extractant glycerol added from the top of the extraction tower 1 is in countercurrent contact in the extraction tower 1 for extraction. The top of the extraction tower 1 obtains the produc...

Embodiment 2

[0033] A method for separating acetophenone and 1-phenylethanol, such as figure 1 As shown, including the following steps:

[0034] (1) The mixture of acetophenone and 1-phenylethanol whose mass percentage concentration of acetophenone is 3% is fed into the first distillation tower 2 for preliminary distillation, and the top of the tower obtains a mass percentage concentration of acetophenone of 41 % Of the mixture of acetophenone and 1-phenylethyl alcohol, 1-phenylethyl alcohol product is obtained at the bottom of the tower (sampling analysis, purity of 99.2%), the operating pressure of the first distillation tower 2 is 0.02MPa, the temperature of the top and bottom of the tower Are the boiling point of the system;

[0035] (2) The tower top mixture obtained in step (1) is pumped into the bottom of the extraction tower 1, and the extractant glycerol added from the top of the extraction tower 1 is in countercurrent contact in the extraction tower 1 for extraction. The top of the e...

Embodiment 3

[0040] A method for separating acetophenone and 1-phenylethanol, such as figure 1 As shown, including the following steps:

[0041] (1) The mixture of acetophenone and 1-phenylethanol whose mass percentage concentration of acetophenone is 95% is fed into the first distillation tower 2 for initial distillation, and the top of the tower obtains a mass percentage concentration of acetophenone of 96.2 % Of the mixture of acetophenone and 1-phenylethyl alcohol, 1-phenylethyl alcohol product is obtained at the bottom of the tower (sample analysis, purity is 99.7%), the operating pressure of the first distillation tower 2 is 0.001MPa, the temperature of the top and bottom of the tower Are the boiling point of the system;

[0042] (2) The tower top mixture obtained in step (1) is pumped into the bottom of the extraction tower 1, and the extractant glycerol added from the top of the extraction tower 1 is in countercurrent contact in the extraction tower 1 for extraction. The top of the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com