Preparation method of gamma-valerolactone

A technology of valerolactone and catalyst, which is applied in the application field of metal catalysts in the preparation of γ-valerolactone, which can solve the problems of reduction of catalytic active sites, agglomeration of metal nanoparticles, low catalyst activity, etc., and achieve increased recyclability The effect of frequency reduction, reduction of agglomeration and reduction of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] First add 0.1g RuCl 3 ·nH 2 O was dissolved in 5 g of deionized water, impregnated with 1 g of SBA-15, and dried overnight to obtain RuCl 3 / SBA-15 template; then dissolve 1.25g glucosamine hydrochloride in 5g deionized water, add 0.5ml concentrated sulfuric acid, impregnate RuCl 3 / SBA-15 template; dry at 100°C for 6 hours, and dry at 160°C for 6 hours; then dissolve 0.8g of glucosamine hydrochloride in 3g of water, add 3 drops of concentrated sulfuric acid, and impregnate RuCl again 3 / SBA-15 template; dry at 100°C for 6h, dry at 160°C for 6h; finally, under the protection of inert gas, calcine at 850°C for 3h to obtain a black powder, then remove the silicon template with 10wt% HF, and mix with water-absolute ethanol The solution was washed until neutral, and dried in vacuum at 110°C for 24 hours. The catalyst prepared by the embedding method is marked as Ru-NOMC, and the catalyst prepared in this example is marked as 5% Ru-NOMC.

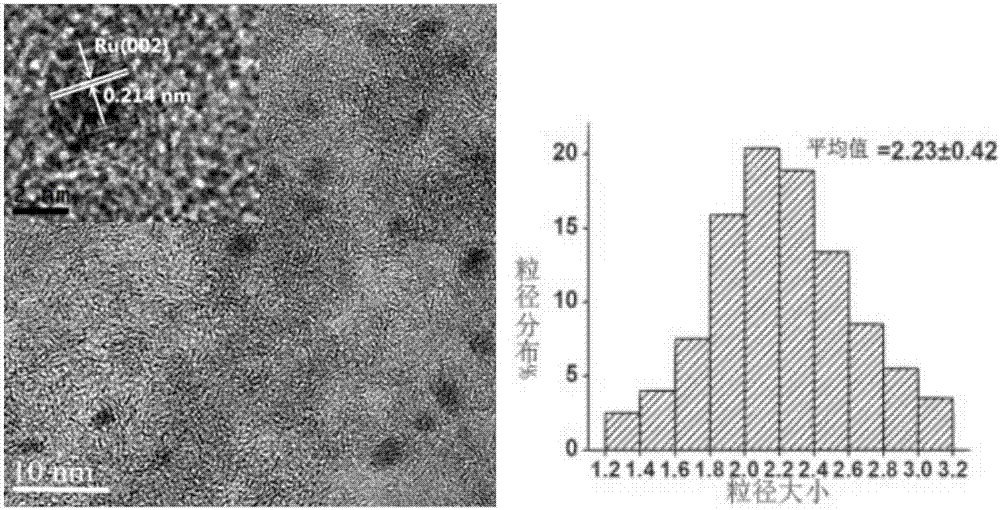

[0047] The TEM image of 5% Ru-NO...

Embodiment 2

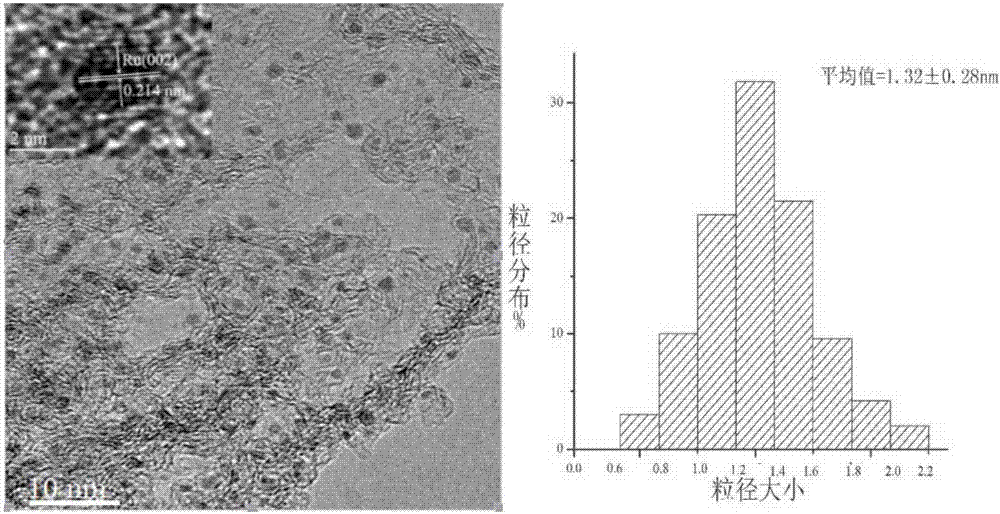

[0049] 0.1g RuCl 3 ·nH 2 O was dissolved in 5 g of deionized water, impregnated with 1 g of SBA-15, and dried overnight to obtain RuCl 3 / SBA-15 template; then dissolve 1.25g glucosamine hydrochloride in 5g deionized water, add 0.5ml concentrated sulfuric acid, impregnate RuCl 3 / SBA-15 template; dry at 100°C for 6h, 160°C for 6h; then under the protection of inert gas, calcined at 850°C for 3h to obtain a black powder, then remove the silicon template with 10wt% HF, and mix with water-absolute ethanol The solution was washed until neutral, and dried in vacuum at 110°C for 24 hours.

[0050] In the catalyst prepared in this embodiment, the average particle diameter of the Ru nanoparticles is 1.53±0.31 nm.

Embodiment 3

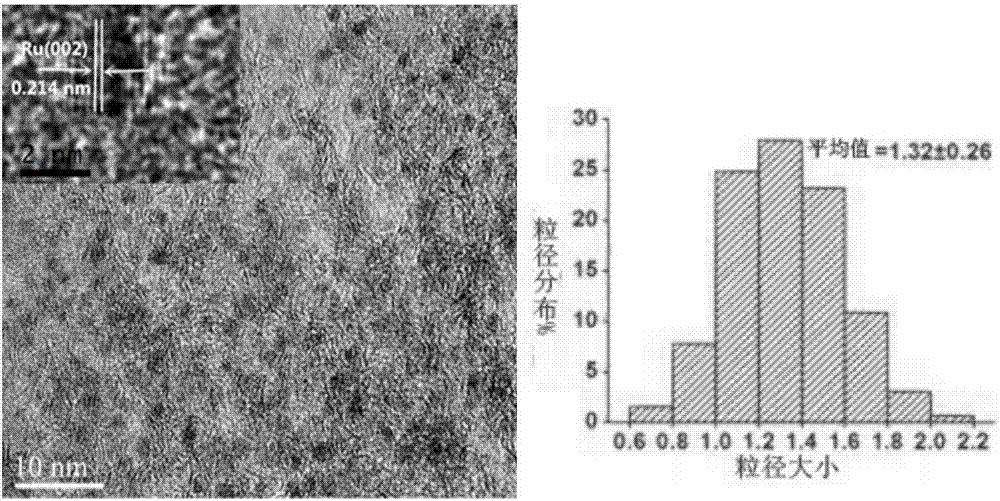

[0052] 0.1g RuCl 3 ·nH 2 O was dissolved in 5 g of deionized water, impregnated with 1 g of SBA-15, and dried overnight to obtain RuCl 3 / SBA-15 template; then dissolve 1.25g glucosamine hydrochloride in 5g deionized water, add 0.5ml concentrated sulfuric acid, impregnate RuCl 3 / SBA-15 template; dry at 160°C for 12h; then dissolve 0.8g of glucosamine hydrochloride in 3g of water, add 3 drops of concentrated sulfuric acid, and impregnate RuCl again 3 / SBA-15 template; dry at 160°C for 12h; finally, under the protection of inert gas, calcine at 850C for 3h to obtain a black powder, then remove the silicon template with 10wt% HF, and wash with water-absolute ethanol mixed solution until neutral, Vacuum drying at 110°C for 24 hours is enough.

[0053] In the catalyst prepared in this embodiment, the average particle diameter of the Ru nanoparticles is 1.44±0.29 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com