Water-based interface fusion agent suitable for synthetic leather

A technology of fusion agent and synthetic leather, applied in the field of synthetic leather functional auxiliaries, can solve the problems of inability to meet product use requirements, reduce the surface quality of synthetic leather, unclear texture of synthetic leather, etc., and achieve excellent interface fusion and excellent surface quality. , Improve the effect of poor polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

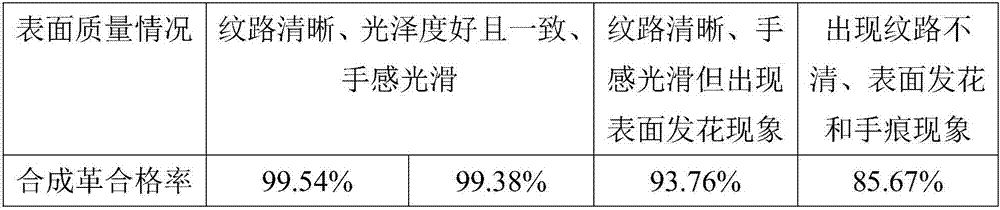

Embodiment 1

[0027] (1) Add 1 part of activated clay, 0.5 part of polyaluminum sulfate and 0.2 part of sepiolite fiber to 3 parts of polyethylene glycol 4000, and heat up to 80-85 ° C at a heating rate of 5 ° C / min and mix for 10 min. Then add 1 part of hydrogenated palm oil and 0.05 part of bistrifluoromethanesulfonimide, continue to heat up to 110-115 ° C at a heating rate of 5 ° C / min and mix for 10 min, then naturally cool to room temperature to obtain material I;

[0028] (2) Add 10 parts of oxidized polyethylene wax-hydrolyzed polymaleic anhydride graft copolymer and 3 parts of hydroxypropyl methylcellulose to 100 parts of water, and heat up to reflux state at a heating rate of 5°C / min and keep mixing 10 minutes, then add 10 parts of cationic polyacrylamide and 5 parts of water-soluble modified cross-linked povidone, continue to reflux and heat-preserve and mix for 5 minutes, and then naturally cool to room temperature to obtain material II;

[0029] (3) Add material I, 10 parts ...

Embodiment 2

[0034] (1) Add 1 part of activated clay, 0.5 part of polyaluminum sulfate and 0.1 part of sepiolite fiber to 2 parts of polyethylene glycol 4000, and heat up to 80-85 ° C at a heating rate of 5 ° C / min and mix for 10 min. Then add 0.5 parts of hydrogenated palm oil and 0.1 parts of bistrifluoromethanesulfonimide, continue to heat up to 110-115°C at a heating rate of 5°C / min and mix for 10 minutes, then naturally cool to room temperature to obtain material I;

[0035] (2) Add 5 parts of oxidized polyethylene wax-hydrolyzed polymaleic anhydride graft copolymer and 5 parts of hydroxypropyl methylcellulose to 100 parts of water, and heat up to reflux state at a heating rate of 5°C / min and keep mixing 10 minutes, then add 15 parts of cationic polyacrylamide and 3 parts of water-soluble modified cross-linked povidone, continue to reflux and heat-preserve and mix for 5 minutes, and then naturally cool to room temperature to obtain material II;

[0036](3) Add material I, 15 parts o...

Embodiment 3

[0041] (1) Add 1 part of activated clay, 0.5 part of polyaluminum sulfate and 0.1 part of sepiolite fiber to 2 parts of polyethylene glycol 4000, and heat up to 80-85 ° C at a heating rate of 5 ° C / min and mix for 10 min. Then add 0.5 parts of hydrogenated palm oil and 0.1 parts of bistrifluoromethanesulfonimide, continue to heat up to 110-115°C at a heating rate of 5°C / min and mix for 10 minutes, then naturally cool to room temperature to obtain material I;

[0042] (2) Add 5 parts of oxidized polyethylene wax-hydrolyzed polymaleic anhydride graft copolymer and 5 parts of hydroxypropyl methylcellulose to 100 parts of water, and heat up to reflux state at a heating rate of 5°C / min and keep mixing 10 minutes, then add 15 parts of cationic polyacrylamide and 3 parts of cross-linked povidone, continue to reflux and heat-preserve and mix for 5 minutes, and then naturally cool to room temperature to obtain material II;

[0043] (3) Add material I, 15 parts of cold-soluble polyvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com