Biological clean type composite fuel and preparation method thereof

A composite fuel, clean technology, applied in the fields of biochemical equipment and methods, microorganism-based methods, fuels, etc., can solve the problems of low desulfurization efficiency and long operation cycle, achieve good ecological benefits, simple preparation process, repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

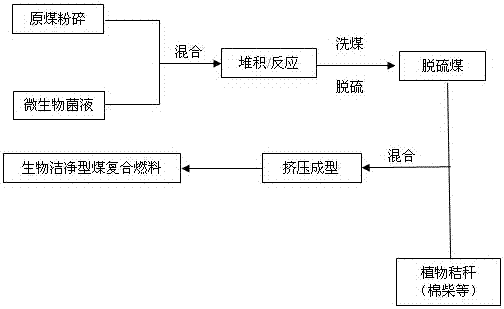

Method used

Image

Examples

Embodiment 1

[0042] (1) Crush 100 parts of lean coal until the particle size is less than 10mm, add 2 parts of water and 1 part of microbial bacterial solution, mix well, and accumulate and react at room temperature for 6 days;

[0043] (2) washing the lean coal after the stacking reaction in step (1) with water while stirring, drying after filtering, so that the moisture content is less than 20%, and obtaining the desulfurized coal after the microbial bacterial liquid treatment;

[0044] (3) Add 20 parts of cottonwood stalks and 5 parts of water to the desulfurized coal treated with the microbial liquid in step (2), the length of the cottonwood stalks is 10-15 mm, stir and mix well, and pass through the briquette forming equipment Extrude for 40 minutes at a temperature of 180°C and a pressure of 15 tons, so that the moisture content is less than 9%;

[0045] (4) The briquettes extruded in step (3) are cooled and demolded to obtain a bio-clean briquette composite fuel product.

[0046] A...

Embodiment 2

[0049] (1) Grinding 120 parts of lean coal until the particle size is below 9mm, adding 3 parts of water and 1.4 parts of microbial bacterial solution, mixing, and stacking reaction at room temperature for 7 days;

[0050] (2) washing the lean coal after the stacking reaction in step (1) with water while stirring, drying after filtering, so that the moisture content is less than 20%, and obtaining the desulfurized coal after the microbial bacterial liquid treatment;

[0051] (3) Add 35 parts of cottonwood stalks and 8 parts of water to the desulfurized coal treated with the microbial liquid in step (2), the length of the cottonwood stalks is 10-15 mm, stir and mix well, and pass through the briquette forming equipment Extrude for 50 minutes at a temperature of 200°C and a pressure of 20 tons, so that the moisture content is less than 9%;

[0052] (4) The briquettes extruded in step (3) are cooled and demolded to obtain a bio-clean briquette composite fuel product.

[0053] Ac...

Embodiment 3

[0056] (1) Grinding 80 parts of lean coal until the particle size is below 15mm, adding 4 parts of water and 1.6 parts of microbial bacterial solution, mixing, and stacking reaction at room temperature for 10 days;

[0057] (2) washing the lean coal after the stacking reaction in step (1) with water while stirring, drying after filtering, so that the moisture content is less than 20%, and obtaining the desulfurized coal after the microbial bacterial liquid treatment;

[0058] (3) Add 15 parts of cottonwood stalks and 3 parts of water to the desulfurized coal treated with microbial liquid in step (2). Extrude for 40 minutes at a temperature of 180°C and a pressure of 15 tons, so that the moisture content is less than 9%;

[0059] (4) The briquettes extruded in step (3) are cooled and demolded to obtain a bio-clean briquette composite fuel product.

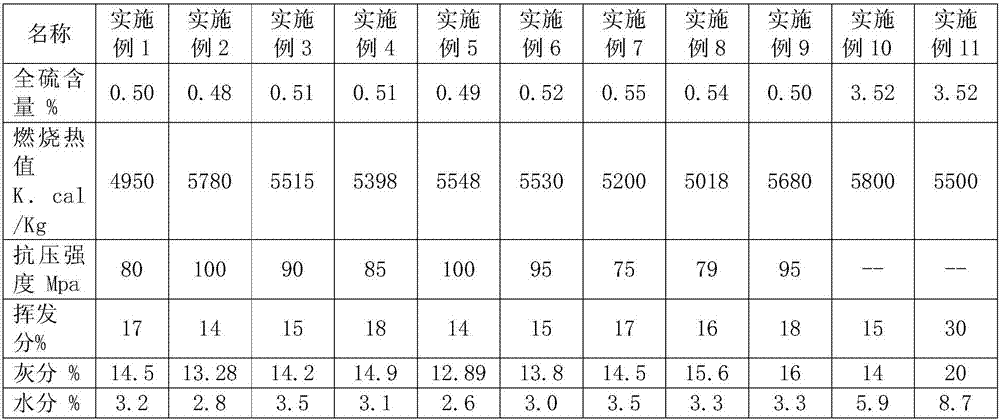

[0060] According to the determination method of total sulfur in coal specified in GB / T 214-2007, the total sulfur content of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com