Culture medium for fermenting polymyxin B sulfate and method for fermenting and producing polymyxin B sulfate

A technology of polymyxin sulfate and culture medium, applied in the field of microbial fermentation, can solve problems such as difficult removal of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

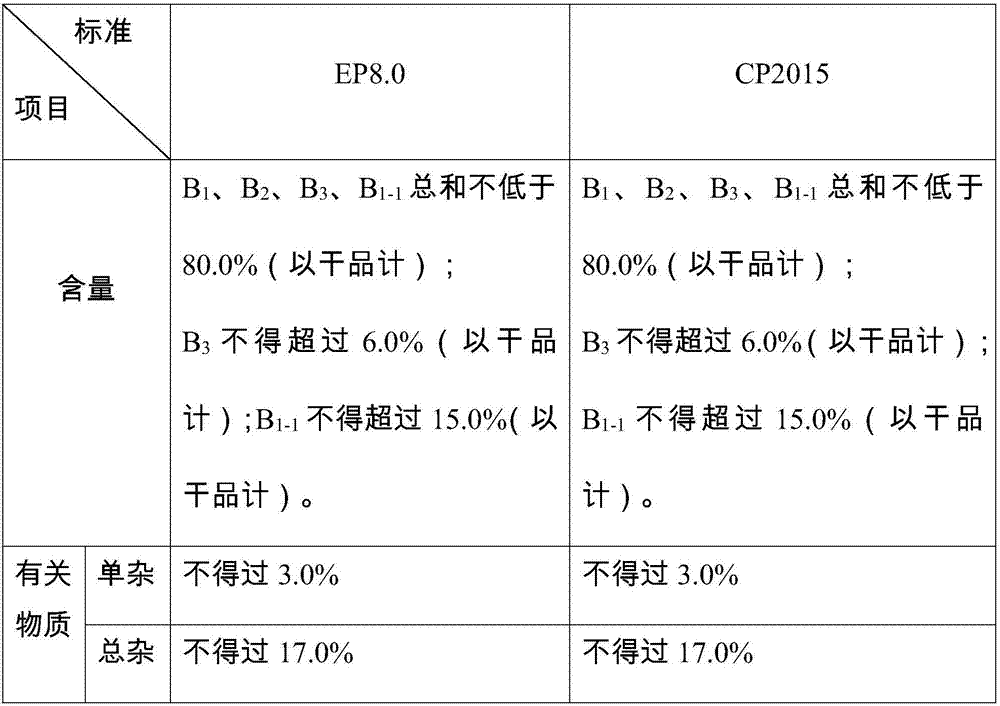

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Seed solution culture method: dig out about 1cm of polymyxin B sulfate slant culture with an inoculation shovel 2 The size is inserted into the seed medium of the shaker flask, wherein the shaker flask adopts a 500ml Erlenmeyer flask containing 70-80ml of the seed medium, and the shaker rotates at 220rpm and cultures at 29°C for 14-18 hours. The composition of the seed medium is: flour 8g / 100ml, yeast extract powder 0.3g / 100ml, dipotassium hydrogen phosphate 0.015g / 100ml, calcium carbonate 0.3g / 100ml, ammonium sulfate 0.45g / 100ml.

[0052] Put the seed culture of Paenibacillus polymyxa, a polymyxin B sulfate-producing bacterium, into the fermentation medium containing the following ingredients: flour 10g / 100ml, high-temperature amylase 4g / 100ml, cottonseed cake powder 1g / 100ml, corn steep liquor 0.5ml / 100ml, dipotassium hydrogen phosphate 0.015g / 100ml, ammonium sulfate 0.4g / 100ml, calcium carbonate 0.3g / 100ml, defoamer 0.05ml / 100ml, inoculum size 7%, temperature 29°C, ...

Embodiment 2

[0062] Put the seed culture of Paenibacillus polymyxa, a polymyxin B sulfate-producing bacterium, into the fermentation medium containing the following ingredients: flour 8g / 100ml, high-temperature amylase 5g / 100ml, cottonseed cake powder 0.8g / 100ml, corn steep liquor 0.8ml / 100ml, dipotassium hydrogen phosphate 0.012g / 100ml, ammonium sulfate 0.5g / 100ml, calcium carbonate 0.25g / 100ml, defoamer 0.06ml / 100ml, inoculum size 10%, temperature 30°C, culture for 46 hours and then end fermentation.

[0063] The fermentation broth and the extracted finished product were tested by high-pressure liquid phase with the external standard method, and the peak area ratios of the components and impurities are shown in Table 2 below.

[0064] Table 2 The peak area ratio of each component and impurity of the fermentation product in Example 2

[0065] Detection situation B 2P Proportion%

[0066] As can be seen from the results in Table 2, the main impurity B in the finished product ...

Embodiment 3

[0068]Put the seed culture of Paenibacillus polymyxa, a polymyxin B sulfate-producing bacterium, into the fermentation medium containing the following ingredients: flour 11g / 100ml, high-temperature amylase 3.5g / 100ml, cottonseed meal 1.5g / 100ml, corn steep liquor 0.4 ml / 100ml, dipotassium hydrogen phosphate 0.03g / 100ml, ammonium sulfate 0.3g / 100ml, calcium carbonate 0.5g / 100ml, defoaming agent 0.04ml / 100ml, inoculum size 15%, temperature 28°C, culture for 42 hours and end fermentation .

[0069] The fermentation broth and the extracted finished product were tested by high-pressure liquid phase with the external standard method, and the peak area ratios of the components and impurities are shown in Table 3 below.

[0070] Table 3 The peak area ratio of each component of the fermentation product and impurities in Example 3

[0071] Detection situation B 2P Proportion%

[0072] As can be seen from the results in Table 3, the main impurity B in the finished product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com