Ultra-fine grain ferrite/nano bainite dual-phase medium carbon steel and preparation method thereof

A nano-bainite and ferrite technology, applied in the field of steel material engineering, can solve the problems of low tensile strength and insufficient toughness, and achieve the effects of low yield ratio, easy control, and high strength and plastic product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A. According to the mass percentage of C 0.35, Si 1.55, Mn 0.74, Cr 0.51, Mo0.2, P 0.006, S 0.002, the balance is the proportion of Fe and unavoidable impurities, calculate the feeding ratio, and use it in a vacuum medium frequency induction furnace It is melted in a medium and poured into a cylindrical steel ingot with a diameter of 170 mm, and refined in a vacuum.

[0023] B. Annealing and hot rolling: heat the steel ingot to 1220°C for 2 hours for homogenization treatment, and air-cool it to 1150°C to start rolling. The final rolling temperature is 880°C. After 6 passes of rolling, it is air-cooled to room temperature after rolling to obtain 20 mm thick hot rolled slab.

[0024] C. Quenching: reheat the hot-rolled slab to 920° C. in the furnace, keep it warm for 40 minutes, and put it into oil to quench and cool to room temperature after being out of the furnace to obtain a quenched slab.

[0025] D. Warm rolling: put the quenched slab into a furnace at 550°C for 1 ...

Embodiment 2

[0033] A. According to the mass percentage of C 0.30, Si 1.70, Mn 0.78, Cr 0.45, Mo0.20, P 0.003, S 0.001, the balance is the ratio of Fe and unavoidable impurities, calculate the feeding ratio, and put it in the vacuum medium frequency induction furnace It is melted in a medium and poured into a cylindrical steel ingot with a diameter of 170 mm, and refined in a vacuum.

[0034] B. Annealing and hot rolling: heat the steel ingot to 1220°C for 2 hours for homogenization treatment, and air-cool it to 1150°C to start rolling. The final rolling temperature is 880°C. After 7 passes of rolling, it is air-cooled to room temperature after rolling to obtain 20 mm thick hot-rolled slabs.

[0035] C. Quenching: reheat the hot-rolled slab to 920° C. in the furnace, keep it warm for 1 hour, put it in oil and quench it to room temperature after being out of the furnace, and obtain the quenched slab.

[0036]D. Warm rolling: put the quenched slab into a furnace at 550°C to keep it warm for...

Embodiment 3

[0041] The difference from Example 1 is: Step D, putting the quenched slab into a furnace at 570 °C for 1 h, taking it out of the furnace to carry out multi-pass warm rolling deformation with a total reduction of 40%, and then air cooling to room temperature to obtain Warm-rolled sheet with a thickness of 12 mm; step E, put the warm-rolled sheet into a furnace with a temperature of 780 °C, keep it warm for 0.5 h, then quickly put it into a salt-bath furnace with a temperature of 240 °C for 2 h, and then take it out of the furnace and air-cool it to room temperature.

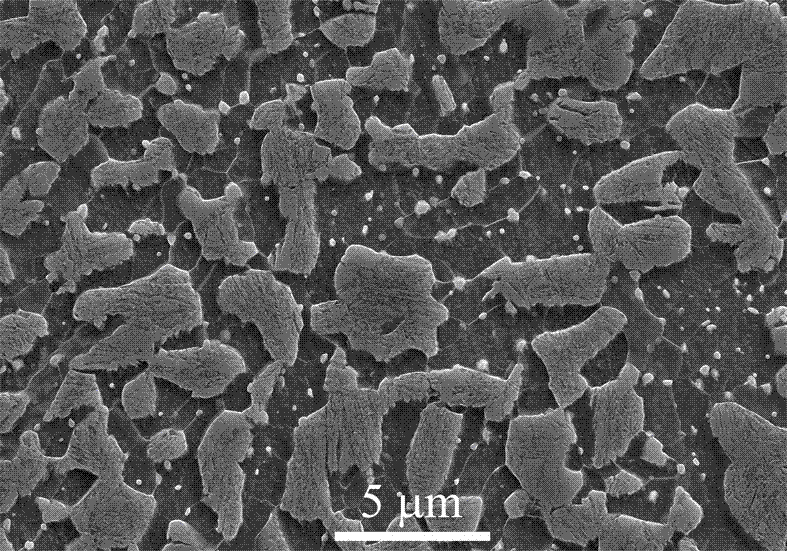

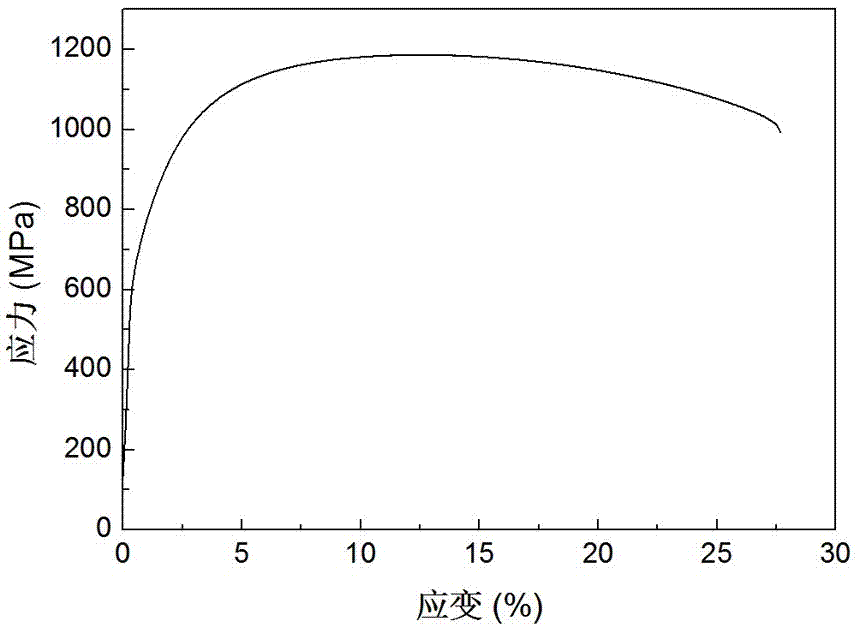

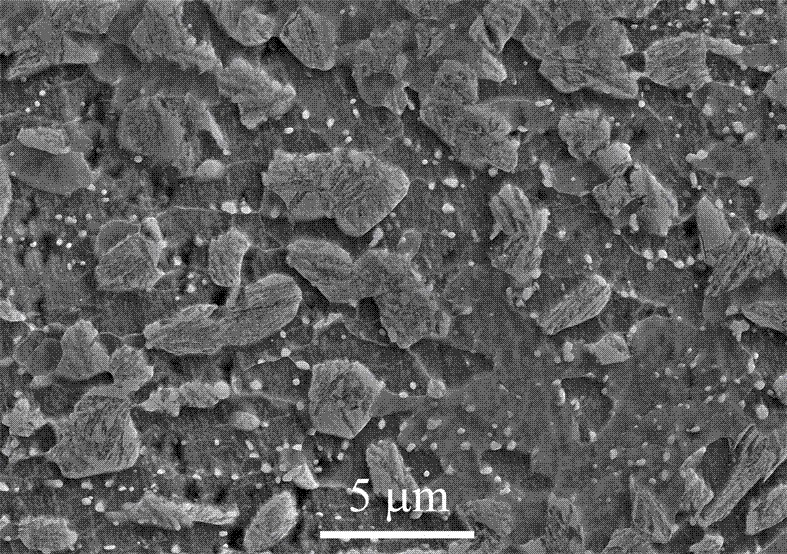

[0042] A scanning electron microscope (SEM) analysis and a tensile test were carried out on the plates prepared in this example, and the results are shown in Table 1.

[0043] The results show that: the ultra-fine-grained ferrite / nano-bainite dual-phase steel prepared in this example has high strength, high plasticity, low yield ratio, high strength-plastic product, and good comprehensive mechanical properties. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com